Welcome!

JH21 series Pneumatic Clutch punch press

- 7 days

- T/T L/C D/P D/A

- 100 Piece / Pieces per Month

Basic Info

| Brand Name | HR | Model Number | JH21 | Place of Origin | China |

|---|

Product Description

Product Description

The machine features fine steel plates welded machine body, tempering treatment (or vibration relief), shot blasting, rigidness, accuracy and stability.

Vertical located crank shaft, compact structure; the crank shaft undergoes grinding treatment after high frequency quenching, which has a good smooth finish and rotates flexibly; lengthened rectangle hex guideway with a surface of bronze plate, which has high guide accuracy.

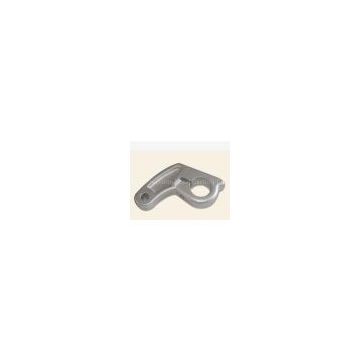

Pneumatic dual balance cylinder, balanced sliding block and punch weight, which reduce impact and noise, eliminate the clearance between connecting rod and sliding block, reduce the impact and wear of the stress parts. The whole machine adopt PLC centralized control, the gas circuits adopt imported safety dual valve, which can achieve jog, inch, single and continuous punching; the key parts such as sliding block, guideways, worktable plate, connecting rod, and are all castings made of resin sand, which improved the surface roughness 1-2 level, and improve the size accuracy 2-3 level.

The 60T-level machines adopt the electrical control device to adjust the die height. Fine configuration, the key parts like pneumatic components, electrical components, sealing parts, buttons and etc all adopt imported parts. There are optional dry or wet friction clutch, and optional hydraulic overload protection device or press-down type safety device, all of them can be equipped with automatic lubrication, photoelectric protection, frequency conversion and speed control, air blowing device and etc according to customer needs.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Recommended Products

Recently Viewed

Wheeled slip loader rotary small forklift miniature loader

Wheeled slip loader rotary small forklift miniature loader High quality sintered friciton material non-asbestos brake pad

High quality sintered friciton material non-asbestos brake pad Slip loaders can be installed with hammer sweepers

Slip loaders can be installed with hammer sweepers Micro-slip loader Small forklift for operation in narrow areas of the farm Multi-functional transport handling loading vehicle video miniature

Micro-slip loader Small forklift for operation in narrow areas of the farm Multi-functional transport handling loading vehicle video miniature Mini loader interior decoration forklift belongs to crawler loader operating technology

Mini loader interior decoration forklift belongs to crawler loader operating technology

Contact Us

AnHui Lai-Fu NC Machine Tool Co.,Ltd