Welcome!

Semi Automatic Small Hang Plating Machine Metal Electroplating Machine for Production Line

Product Description

Electroplated copper is used as a base for mold, nickel, chromium, silver, and gold plating to repair worn parts, prevent localized carburization, and improve electrical conductivity. It is divided into two methods: alkaline copper plating and acidic copper plating. Generally, in order to obtain a thin, fine, and smooth copper coating, parts such as steel with oil rust removed from the surface are used as cathodes, and pure copper plates are used as anodes. They are hung in an alkaline electroplating solution containing copper cyanide, sodium cyanide, and sodium carbonate to undergo alkaline (cyanide) copper plating. In order to obtain a thicker copper coating, it is necessary to first conduct alkaline copper plating on the plated piece, and then place it in an electrolyte containing copper sulfate, nickel sulfate, and sulfuric acid to conduct acidic copper plating.

During electroplating, the plated metal or other insoluble material is used as the anode, and the workpiece to be plated is used as the cathode. The cations of the plated metal are reduced on the surface of the workpiece to be plated to form a coating. In order to eliminate the interference of other cations and make the coating uniform and firm, it is necessary to use a solution containing the metal cations of the coating as the plating solution to maintain the concentration of the metal cations of the coating unchanged. The purpose of electroplating is to coat the substrate with a metal coating that changes the surface properties or dimensions of the substrate. Electroplating can enhance the corrosion resistance of metals (most plating metals use corrosion resistant metals), increase hardness, prevent abrasion, improve electrical conductivity, smoothness, heat resistance, and surface aesthetics.

Recommended Products

Recently Viewed

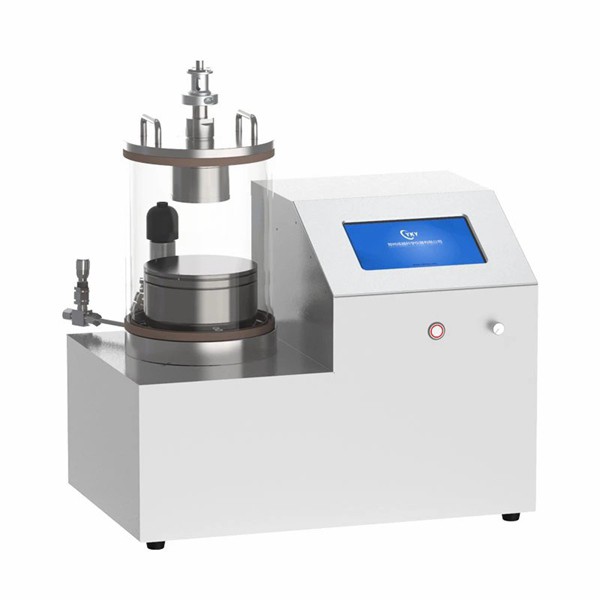

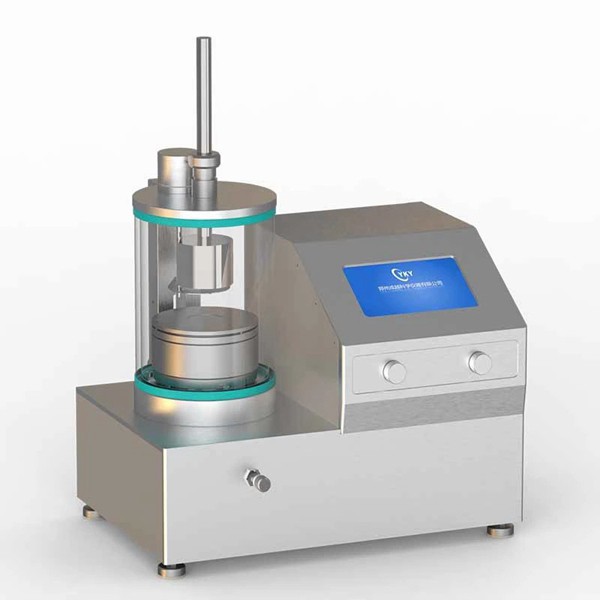

New Design Factory Price Triple Targets Magnetron Sputter Coater with DC and RF Power Supply for Multilayer Films

New Design Factory Price Triple Targets Magnetron Sputter Coater with DC and RF Power Supply for Multilayer Films High Quality High Vacuum Triple Target Magnetron Sputter Coater for Thin Film Coating Process

High Quality High Vacuum Triple Target Magnetron Sputter Coater for Thin Film Coating Process Wholesale Price Dual-Target Magnetron Generator 300W Sputter Coater

Wholesale Price Dual-Target Magnetron Generator 300W Sputter Coater China Supplier High Vacuum Triple Target Magnetron Sputter Coater for Thin Film Coating Process

China Supplier High Vacuum Triple Target Magnetron Sputter Coater for Thin Film Coating Process New Design Factory Price Magnetron Sputtering Vacuum Metallizer PVD Sputter Coater

New Design Factory Price Magnetron Sputtering Vacuum Metallizer PVD Sputter Coater

Contact Us

Linyi City Lanshan District Wenbo Power Supply Equipment Factory