Welcome!

Industrial Automatic industrial guillotine paper cutter Cutting Machine Round Paper Cutter

Product Description

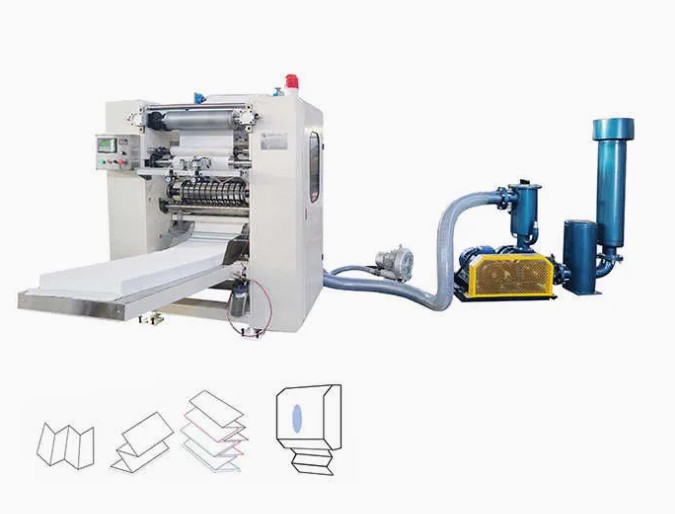

A paper cutter, as the name suggests, is a machine specifically designed for cutting paper. It is manufactured with precision mechanical structure and high-quality materials, ensuring stable performance and precise cutting effect even during long-term use. According to different needs, paper cutting machines can be divided into two types: manual and electric. The manual paper cutter is easy to operate and suitable for small batch and low-frequency cutting needs; Electric paper cutting machines, on the other hand, have higher efficiency and accuracy, making them suitable for large-scale and high-frequency cutting tasks.

matters needing attention

Cutting ability: Determine the maximum paper thickness that the machine can handle.

Safety function: Find blade protection devices and safety locks to prevent accidents from occurring.

Cutting mechanism: Choose between manual, electric, or hydraulic systems according to your needs.

The advantages of paper cutting machines

Accuracy: Ensure accurate cutting, reduce errors and waste.

Efficiency: Accelerate the cutting process, save time, and improve productivity.

Multifunctionality: can be used for various materials, such as paper, cards, etc.

From the perspective of structure and working principle, the paper cutting machine adopts precise mechanical design. Its core component - the paper cutter, is driven by hydraulic or pneumatic pressure to achieve oblique cutting. This design not only improves cutting efficiency, but also makes the incision smoother and more neat. In addition, modern paper cutting machines are mostly controlled by computers, making operation more convenient and accurate. Through the collaborative work of components such as motors, pulleys, and electronic clutches, the paper cutter can perform precise cutting according to the preset program.

Recommended Products

Recently Viewed

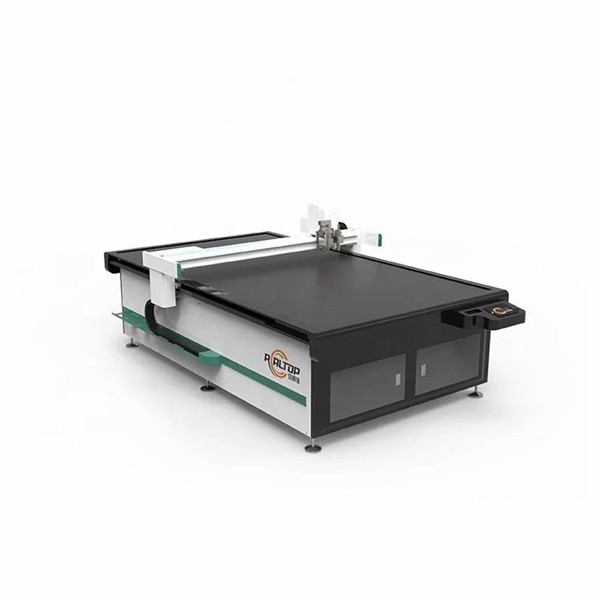

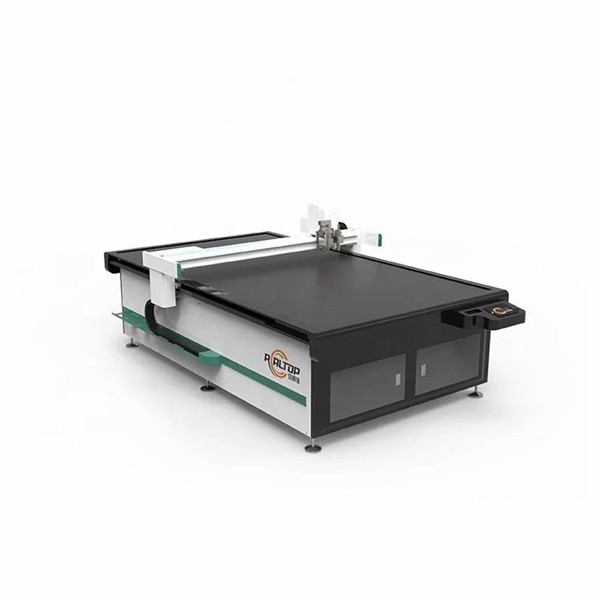

High-speed automatic corrugated carton box machine paperboard cutting machine

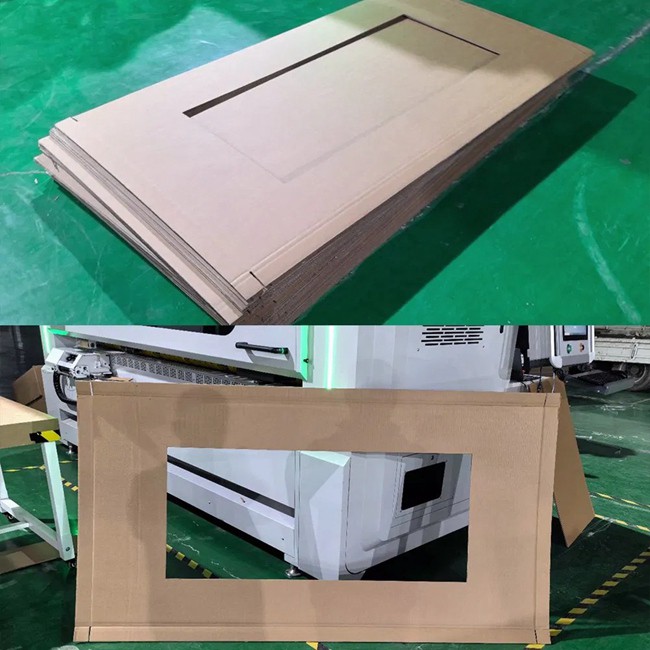

High-speed automatic corrugated carton box machine paperboard cutting machine High-efficiency corrugated cardboard machine with cutting function

High-efficiency corrugated cardboard machine with cutting function Exploring the Efficiency and Versatility of Paperboard Machines

Exploring the Efficiency and Versatility of Paperboard Machines The Ultimate Guide to Paperboard Machines: Revolutionizing the Packaging Industry

The Ultimate Guide to Paperboard Machines: Revolutionizing the Packaging Industry Efficient and Reliable Paperboard Machines: Revolutionizing the Packaging Industry

Efficient and Reliable Paperboard Machines: Revolutionizing the Packaging Industry

Contact Us

Changzhou Kexiang Drying Equipment Co., Ltd.