Welcome!

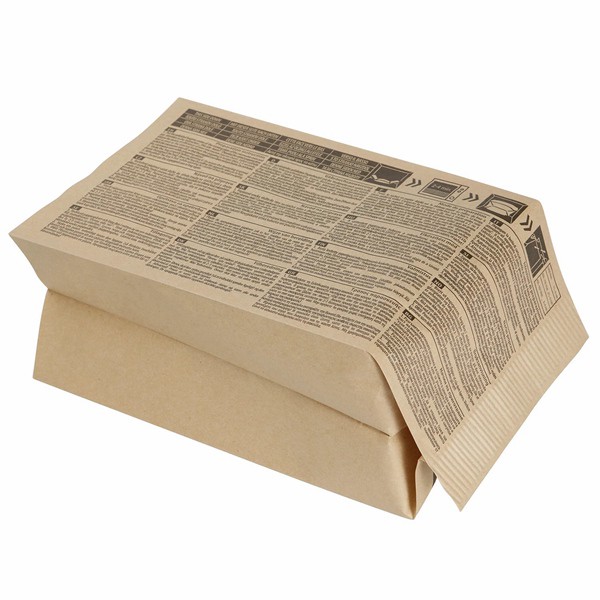

Custom Design Greaseproof Paper Kemasan Makanan Bag with Reflective Film

Product Description

The entire production process focuses on environmental protection, safety, and efficiency, ensuring the high quality and practicality of microwave popcorn paper bags. Meanwhile, with the continuous development of technology, production processes are also constantly optimized and updated to meet the growing needs and expectations of consumers.

The composite paper is then loaded onto a printing machine or printing machine for positioning and gluing. The paper after printing glue is dried and sterilized through a medium temperature drying device to ensure the hygiene and safety of the paper bag. This step also enhances the firmness and durability of the paper bag.

Then, the printed surface paper and inner paper are laminated using a cold adhesive method. This composite method is not only sturdy, but also environmentally friendly, ensuring that the paper bag is not easily layered or damaged during use.

Next, the printed face paper will be subjected to film application on the laminating machine. This step is mainly to increase the durability and sealing of the paper bag, ensuring that it will not break or leak during microwave heating.

The production process of microwave popcorn paper bags is a combination of modern technology and traditional craftsmanship, aimed at manufacturing popcorn packaging that is both safe and convenient. The following are the detailed steps of the production process:

In the fast-paced modern life, microwave popcorn paper bags are loved by consumers for their convenience and deliciousness. This paper bag not only simplifies the process of making popcorn, but also retains the original taste and aroma of popcorn, allowing people to enjoy food while also feeling the ease and joy of life.

Recommended Products

Recently Viewed

Wholesale Empty Plastic Drawstring Packing 25kg 50kg Firewood Vegetable Onion Potato Cabbage Fruit Orange

Wholesale Empty Plastic Drawstring Packing 25kg 50kg Firewood Vegetable Onion Potato Cabbage Fruit Orange Factory Price 50lb 50kg Leno Fruit Vegetable Plastic Packaging Drawstring Bean Onion Potato PP Mesh Net Bag

Factory Price 50lb 50kg Leno Fruit Vegetable Plastic Packaging Drawstring Bean Onion Potato PP Mesh Net Bag Factory Price Anti-UV Vegetable Onions Garlic Potato Fruit Plastic PP Tubular Leno Net Drawstring Mesh Sack Bags

Factory Price Anti-UV Vegetable Onions Garlic Potato Fruit Plastic PP Tubular Leno Net Drawstring Mesh Sack Bags Factory Price Empty Plastic Drawstring Packing 25kg 50kg Firewood Vegetable Onion Potato Cabbage Fruit Orange

Factory Price Empty Plastic Drawstring Packing 25kg 50kg Firewood Vegetable Onion Potato Cabbage Fruit Orange China Factory PE Leno Tubular Plastic Mono Mesh Bag for Packing Vegetables and Fruits

China Factory PE Leno Tubular Plastic Mono Mesh Bag for Packing Vegetables and Fruits

Contact Us

NINGBO BOHONGCHUANGYI INTERNATIONAL CO., LTD.