Welcome!

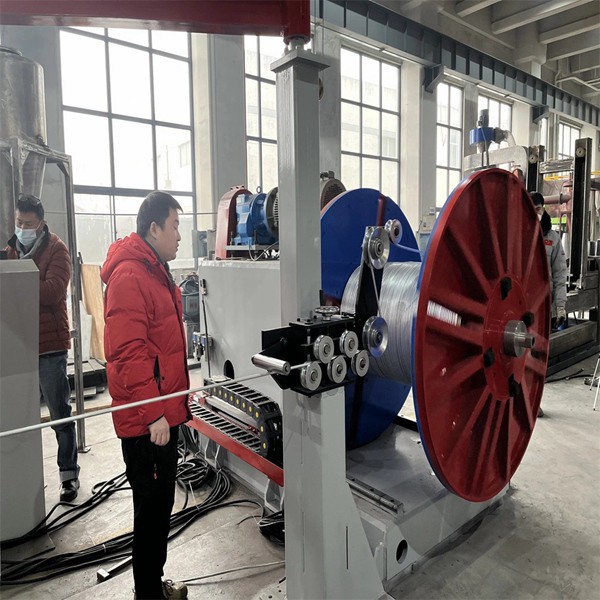

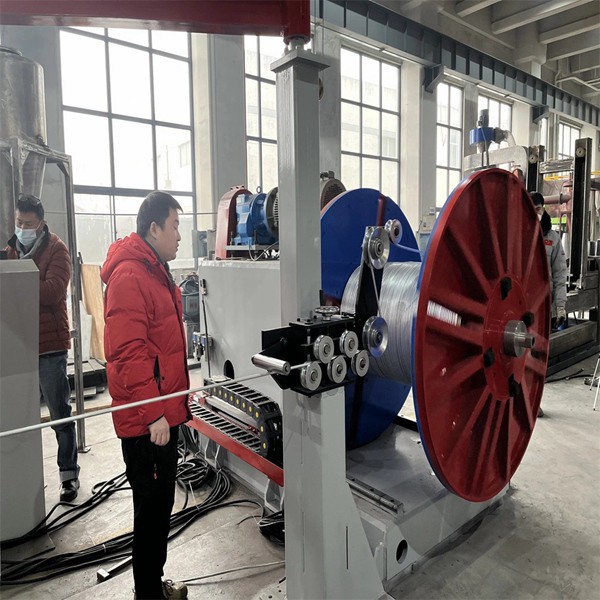

China Manufacture Copper Wire Wrapping Braiding Machine for Choke Transformer

Product Description

By operating the tensioning device to tighten the rope or strip, ensure the firmness of the tying. Finally, tie the rope or thin strip onto the copper wire using a binding device to complete the binding process.

The copper wire winding machine adopts advanced automation technology, greatly improving production efficiency and reducing labor costs. At the same time, the equipment has a fast mold changing function, which can easily adapt to the production needs of wires and cables of different specifications and models.

Copper wire bundling machine is a device used for bundling copper wires. Its working principle is similar to a typical strapping machine, which uses mechanical or electric devices to tighten ropes or thin strips and tie copper wires. Copper wire tying machines are usually made of sturdy metal materials, with a stable structure and support. When using a copper wire bundling machine, first place the copper wire that needs to be bundled on the load module, and then adjust the position of the fixture or mold as needed.

As one of the important equipment in the manufacturing process of wires and cables, copper wire winding machines provide strong support for the development of the wire and cable industry with their efficient and precise performance characteristics. With the continuous progress of technology and the continuous development of the market, copper wire winding machines will continue to play an important role in the wire and cable industry, promoting the sustainable development and innovation of the industry.

Recommended Products

Recently Viewed

China Manufacture Copper Wire Wrapping Braiding Machine for Choke Transformer

China Manufacture Copper Wire Wrapping Braiding Machine for Choke Transformer Factory Hot Sales Sintering Line Copper Wire Wrapping Machine for Wire Harness

Factory Hot Sales Sintering Line Copper Wire Wrapping Machine for Wire Harness China Manufacture Shielded Round Wire Copper Foil Wrap Taping Machine for Choke Transformer

China Manufacture Shielded Round Wire Copper Foil Wrap Taping Machine for Choke Transformer Factory Hot Sales Copper Wire Wrapping Braiding Machine for Choke Transformer

Factory Hot Sales Copper Wire Wrapping Braiding Machine for Choke Transformer Automatic Copper foil winding wrapping packing machine wiring Harness Taping Machine For Wire Harness for Choke Transformer

Automatic Copper foil winding wrapping packing machine wiring Harness Taping Machine For Wire Harness for Choke Transformer

Contact Us

WUHU TRUCHUM ALLOY-COPPER CO., LTD.