Welcome!

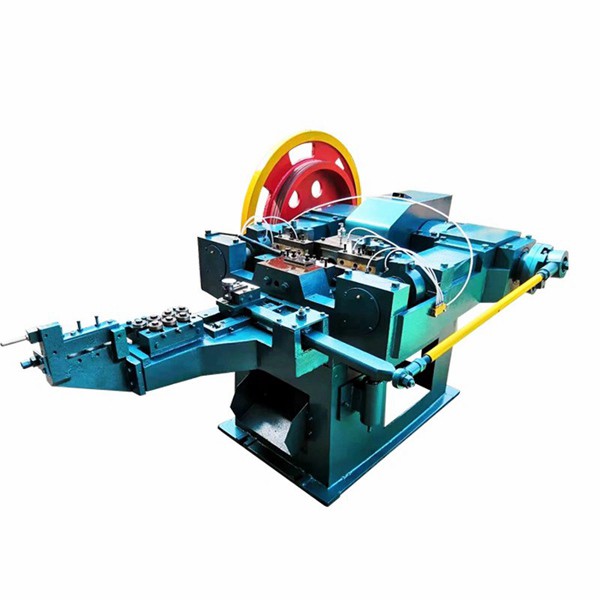

China Factory Steel Iron Nail Making Manufacturing Machine

Product Description

Steel nail manufacturing machine is a specialized mechanical equipment used for producing various specifications and types of steel nails. The steel nail manufacturing machine will pay more attention to the improvement of intelligence and automation, and achieve more efficient and accurate production by introducing advanced control technology and sensor technology. Meanwhile, with the increasing awareness of environmental protection, steel nail manufacturing machines will also pay more attention to energy conservation, emission reduction, and environmental performance improvement.

The steel nail manufacturing machine adopts an automated production process, which can continuously produce and greatly improve production efficiency. Through precise control systems and mechanical structures, the steel nail manufacturing machine can ensure the accurate size and stable quality of the produced steel nails. The steel nail manufacturing machine can adjust production parameters as needed to adapt to different specifications and types of steel nail production. Equipment is usually equipped with comprehensive safety protection devices to ensure the safety of operators.

Steel nail manufacturing machine is an automated production line equipment that integrates functions such as feeding, stamping, cutting, and forming. It can continuously and quickly produce steel nail products that meet standards through high-precision mechanical operation and control systems.

High speed nail making machines are widely used in industries such as construction, furniture manufacturing, and packaging, especially in situations where a large and fast production of nails is required, such as construction sites and furniture factories. High speed nail making machines will develop towards a more intelligent and automated direction, while focusing on energy conservation, emission reduction, and environmental performance improvement. The high-speed nail making machine ensures the accurate size and stable quality of the produced nails through precise control systems and mechanical structures. It can produce various nails with diameters ranging from 2.0mm to 3.5mm and lengths ranging from 45mm to 90mm.

The nail making machine adopts an automated production process, greatly improving production efficiency and reducing production costs. Through precise stamping and cutting systems, nail making machines can produce nails with accurate dimensions and stable quality. The nail making machine can adapt to the production needs of nails of different specifications and materials, and has strong flexibility. The nail making machine adopts multiple safety protection measures to ensure the personal safety of operators.

Recommended Products

Recently Viewed

Customized Wire Straightening Tool with 18 Rollers Copper Wire Straightener

Customized Wire Straightening Tool with 18 Rollers Copper Wire Straightener Wholesale Wire Straightening Tool with 18 Rollers Copper Wire Straightener

Wholesale Wire Straightening Tool with 18 Rollers Copper Wire Straightener Factory Directly Wire Straighteners for Drawing Lines Steel Wire Straightening Machine

Factory Directly Wire Straighteners for Drawing Lines Steel Wire Straightening Machine Wholesale Wire Forming Machine Metal Straightening Machinery Steel Straightener

Wholesale Wire Forming Machine Metal Straightening Machinery Steel Straightener High Quality Wire Forming Machine Metal Straightening Machinery Steel Straightener

High Quality Wire Forming Machine Metal Straightening Machinery Steel Straightener

Contact Us

WuXi JingJie Robot Technology Co., Ltd.