Welcome!

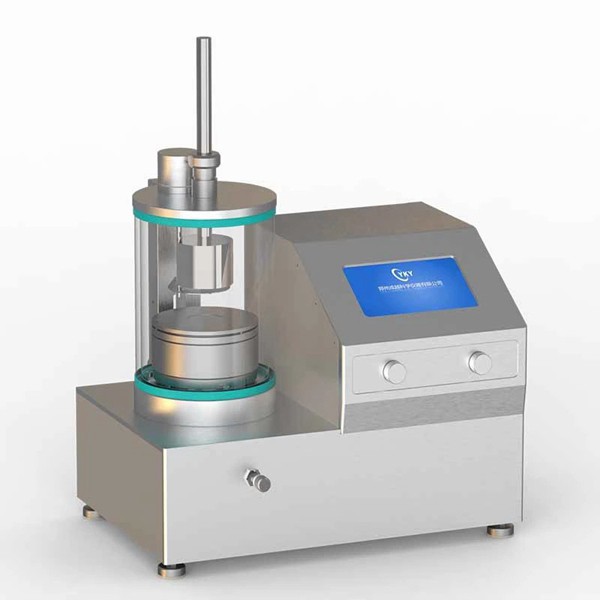

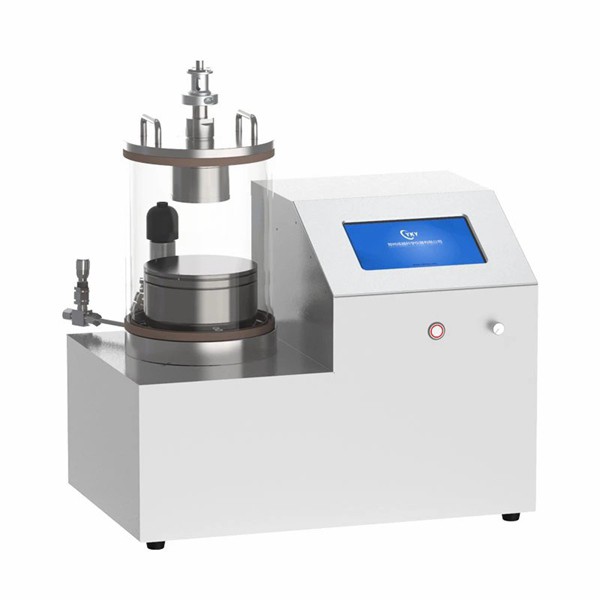

China Supplier Magnetron Sputtering Vacuum Metallizer PVD Sputter Coater

Product Description

Coating machines have been widely used in industries such as semiconductors, optoelectronics, healthcare, and aviation. In the field of chemical drugs, coating technology is used to ensure the purity and stability of materials; In the field of electronic optics, the manufacturing of high-precision components and devices cannot be separated from coating technology; In the fields of machinery and automotive manufacturing, coating technology is used for the treatment of metal surfaces; In the field of medical devices and food packaging, coating technology provides corrosion resistance and wear resistance.

Each type of coating machine has its specific working principle and application field. For example, a physical vapor coating machine utilizes energy such as electric arcs and high frequencies to evaporate or ionize metal and deposit it onto the substrate; The sputtering coating machine uses an arc beam, electron beam, or ion beam to peel off the metal target material and form a thin film.

The basic components include a vacuum system, sedimentation chamber, power supply, and control system. The vacuum system is used to create a vacuum, and the deposition chamber is the main area for depositing thin films. The power supply controls parameters such as material deposition speed and temperature, and the control system ensures that the deposition thickness, uniformity, and quality of the thin film meet the requirements. According to different processes, requirements, and applications, coating machines can be divided into various types, such as physical vapor coating machines, chemical vapor coating machines, ion coating machines, magnetron coating machines, sputtering coating machines, etc.

With the continuous development of materials science, vacuum technology, electronic technology and other fields, sputtering coating technology is also constantly innovating and improving. In the future, sputtering coating machines will pay more attention to technological innovation in improving coating quality, reducing production costs, and improving production efficiency. With the continuous development and improvement of sputtering coating technology, its application fields will also continue to expand. In the future, sputtering coating machines will be more widely used in emerging fields such as new energy, environmental protection, and biomedicine, providing strong support for the development of these fields.

Sputtering coating machine usually consists of vacuum chamber, target material, substrate frame, working gas conveying system, power supply and control system, etc. In the vacuum chamber, gas is evacuated to create a vacuum environment and avoid interference from gas molecules during the sputtering process. The target material is a key component of the sputtering coating machine, usually made of the required material, which is heated and excited by electric arcs, ion beams, or magnetic fields to achieve atomic or molecular sputtering.

Recommended Products

Recently Viewed

New Design Factory Price Triple Targets Magnetron Sputter Coater with DC and RF Power Supply for Multilayer Films

New Design Factory Price Triple Targets Magnetron Sputter Coater with DC and RF Power Supply for Multilayer Films High Quality High Vacuum Triple Target Magnetron Sputter Coater for Thin Film Coating Process

High Quality High Vacuum Triple Target Magnetron Sputter Coater for Thin Film Coating Process Wholesale Price Dual-Target Magnetron Generator 300W Sputter Coater

Wholesale Price Dual-Target Magnetron Generator 300W Sputter Coater China Supplier High Vacuum Triple Target Magnetron Sputter Coater for Thin Film Coating Process

China Supplier High Vacuum Triple Target Magnetron Sputter Coater for Thin Film Coating Process New Design Factory Price Magnetron Sputtering Vacuum Metallizer PVD Sputter Coater

New Design Factory Price Magnetron Sputtering Vacuum Metallizer PVD Sputter Coater

Contact Us

Yantai Haige Machine Tools Co., Ltd.