Welcome!

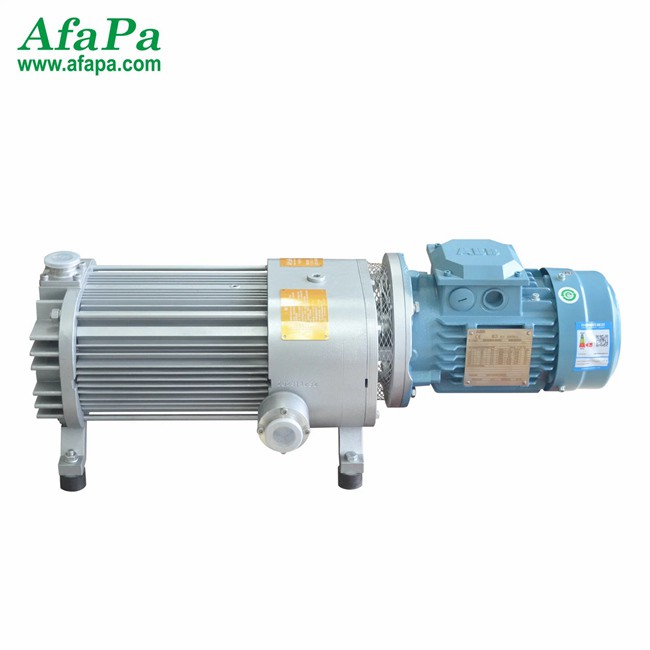

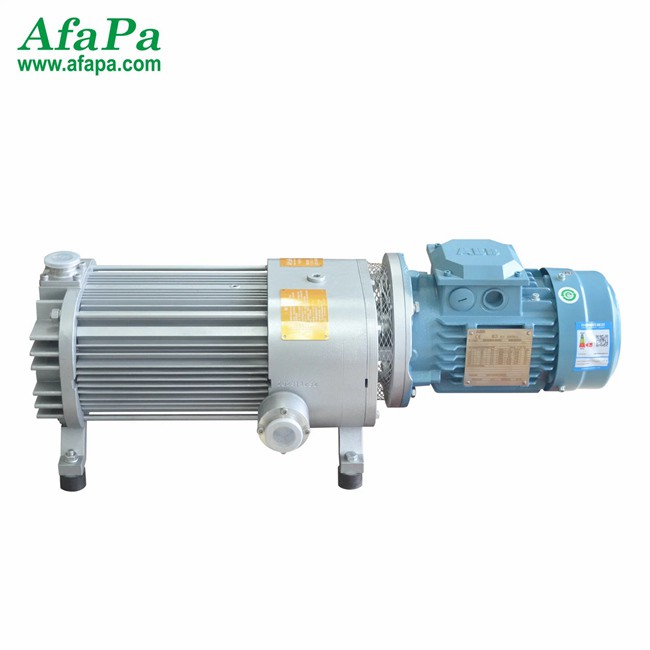

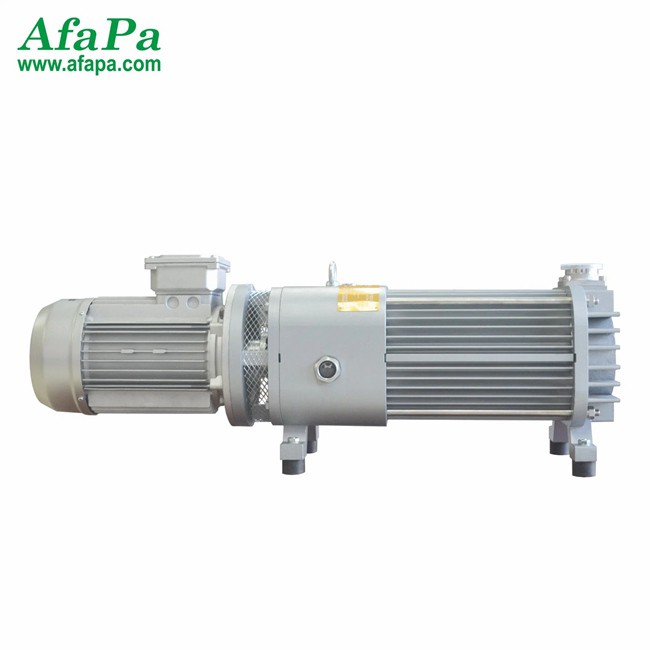

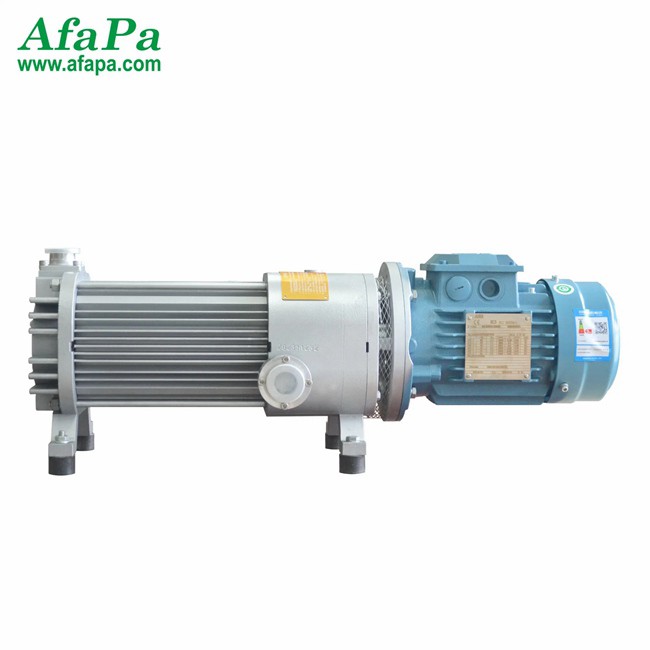

Multifunctional Dry Oil Free Screw Vacuum Pump for Oil Vapor Recycling for PCB Board

Product Description

As an important equipment in industrial production, the application scope and importance of vacuum pumps are constantly expanding. With the advancement of technology and the development of the industry, the types and performance of vacuum pumps will continue to be optimized, providing a more efficient, stable, and reliable vacuum environment for industrial production. In the future, vacuum pumps will continue to play a crucial role in various fields, promoting the progress and development of industrial production.

advantage:

The structure is simple and compact, with the characteristic of isothermal compression.

There is no metal friction surface inside the pump, with minimal wear and gas can be continuously and stably pumped out.

Not sensitive to dust and water vapor in the extracted gas.

The vacuum pump extracts gas from the container being pumped through different mechanisms, thereby creating and maintaining a vacuum state in the space. According to the different working principles, vacuum pumps are mainly divided into two categories: gas capture pumps and gas transfer pumps. Gas capture pumps mainly capture gas molecules through physical or chemical means, such as molecular sieve adsorption vacuum pumps; Gas transfer pumps, on the other hand, transmit gas from one location to another through mechanical movements such as rotation and reciprocating motion, such as reciprocating vacuum pumps and turbine vacuum pumps.

Vacuum pump, as a device that uses mechanical, physical, chemical or physicochemical methods to extract air from the container being pumped to obtain a vacuum environment, plays a crucial role in industrial production. It is widely used in various fields such as metallurgy, chemical industry, food, electronic coating, and aerospace, and has become an indispensable part of modern industry.

Recommended Products

Recently Viewed

Contact Us

Shanghai Afapa Vacuum Technology Co., Ltd.