Welcome!

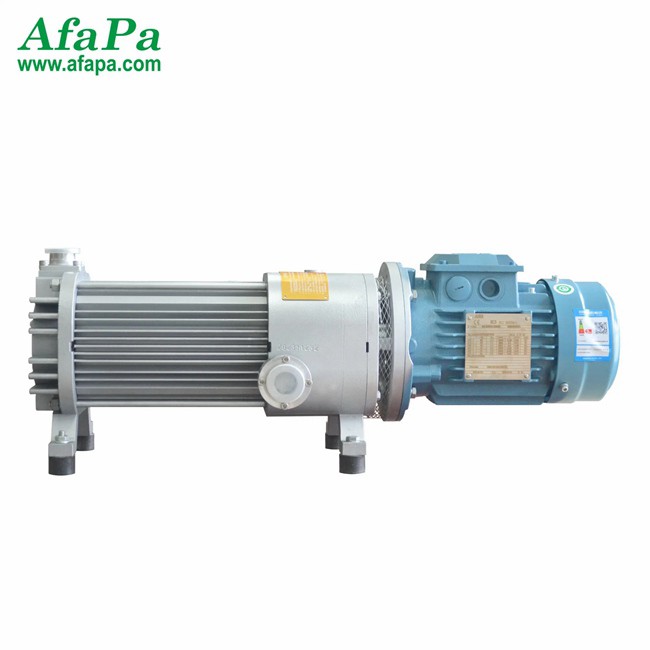

High Efficiency Anti-Explosion Dry Screw Vacuum Pump for Lab Vacuum Distillation

Product Description

An oil-free vacuum pump is a type of pump that does not use lubricants in the chamber to generate vacuum or cool the pump. It achieves gas suction and vacuum creation through specific mechanical structures and working principles. Due to not using oil as a lubricant, it avoids oil pollution and oil vapor emissions, which meets environmental requirements. The oil-free design reduces the maintenance cost of the pump and extends its service life. Due to its unique performance and advantages, oil-free vacuum pumps are widely used in multiple fields.

advantage:

The structure is simple and compact, with the characteristic of isothermal compression.

There is no metal friction surface inside the pump, with minimal wear and gas can be continuously and stably pumped out.

Not sensitive to dust and water vapor in the extracted gas.

Vacuum pumps are widely used in processes such as distillation, drying, degassing, concentration, and reaction in chemical production. For example, in the field of petrochemicals, vacuum pumps are used for crude oil distillation and refining; In organic synthesis, used for degassing operations; In the polymer industry, it is used for degassing and concentration in polymerization reactions. In the pharmaceutical production process, vacuum pumps are used for drying, concentrating, and extracting drugs to ensure the purity and quality of the products.

The reciprocating vacuum pump achieves gas suction through the reciprocating motion of the piston in the pump chamber. When the piston moves outward, the gas in the pump chamber is discharged; When the piston moves inward, the pump chamber is open to the atmosphere and draws in more gas. By continuously repeating this process, the effect of continuous suction is achieved. Liquid ring vacuum pump is similar to reciprocating vacuum pump, but uses liquid as the working medium. There is an eccentric wheel in the pump chamber. When the eccentric wheel rotates, the liquid will form a circulation along the inner wall of the pump chamber, and the gas is sucked in and discharged through the volume change of the liquid ring.

Recommended Products

Recently Viewed

Contact Us

Shanghai Afapa Vacuum Technology Co., Ltd.