Welcome!

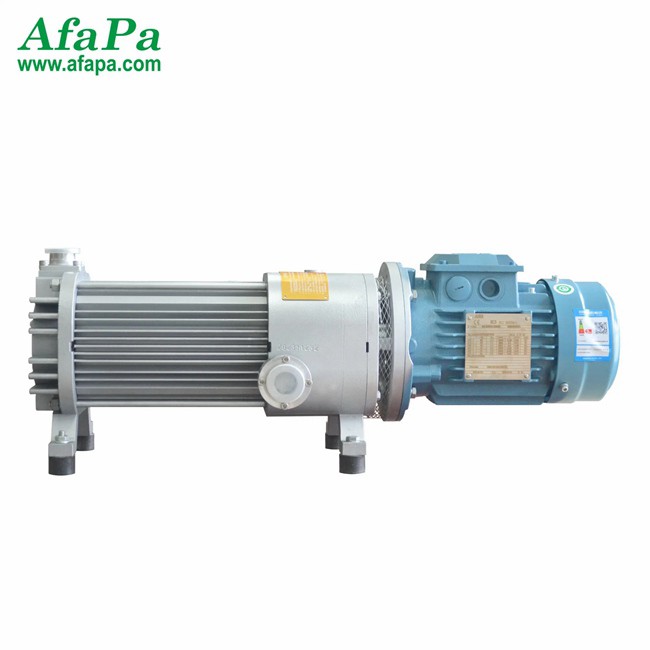

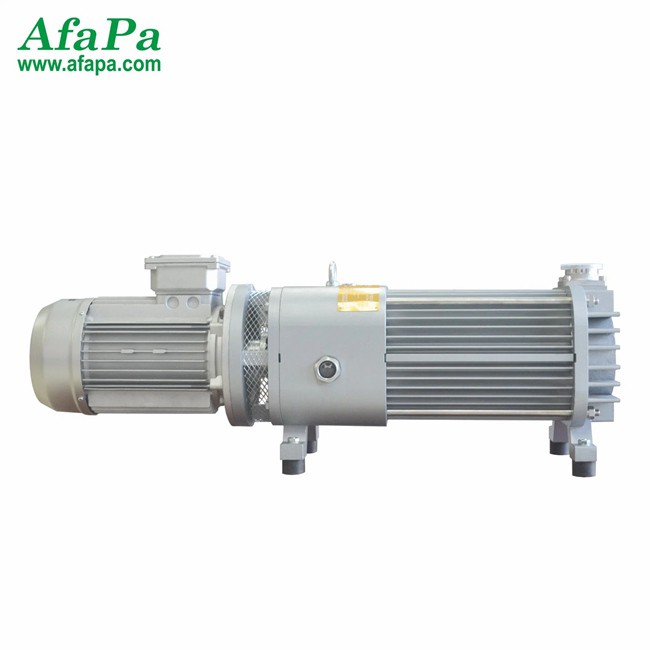

High Efficiency Air Cooled Dry Oil Free Screw Vacuum Pump for Lab Vacuum Distillation

Product Description

Oil free vacuum pumps draw air into the pump through specific mechanical structures such as molecular pumps, dry screw pumps, etc. Compress the gas inside the pump to reduce its volume and increase pressure. The compressed gas is discharged from the pump through the exhaust pipe to form a certain negative pressure, thereby achieving a vacuum effect. Oil free vacuum pump is an environmentally friendly, efficient, and reliable vacuum pump equipment widely used in multiple fields. During the selection and use process, it is necessary to pay attention to relevant matters to ensure its normal operation and extend its service life.

As an important equipment in industrial production, the application scope and importance of vacuum pumps are constantly expanding. With the advancement of technology and the development of the industry, the types and performance of vacuum pumps will continue to be optimized, providing a more efficient, stable, and reliable vacuum environment for industrial production. In the future, vacuum pumps will continue to play a crucial role in various fields, promoting the progress and development of industrial production.

Vacuum pumps play an important role in food packaging and processing. Vacuum packaging can extend the shelf life of food, reduce oxygen exposure, and prevent food oxidation and spoilage. Meanwhile, in the food processing process, vacuum pumps are used for degassing and concentration, improving the quality and taste of food. In the semiconductor production process, a vacuum pump is used to provide an ultra-high vacuum environment to ensure the smooth progress of process operations such as thin film deposition and ion implantation. Vacuum pumps are used to simulate space environments and test the performance and reliability of aerospace devices.

Turbovacuum pumps use the rotation of the turbine to extract gas. A limited working chamber is formed between the turbine and the pump chamber. When the turbine rotates, the gas in the working chamber is discharged and new gas is sucked in. Molecular sieve adsorption vacuum pump utilizes the adsorption effect of molecular sieve on gas to achieve suction. Molecular sieves have a highly porous structure and can selectively adsorb gas molecules. When the molecular sieve is saturated with adsorption, it is released by heating to restore its adsorption capacity.

Recommended Products

Recently Viewed

Contact Us

Shanghai Afapa Vacuum Technology Co., Ltd.