Welcome!

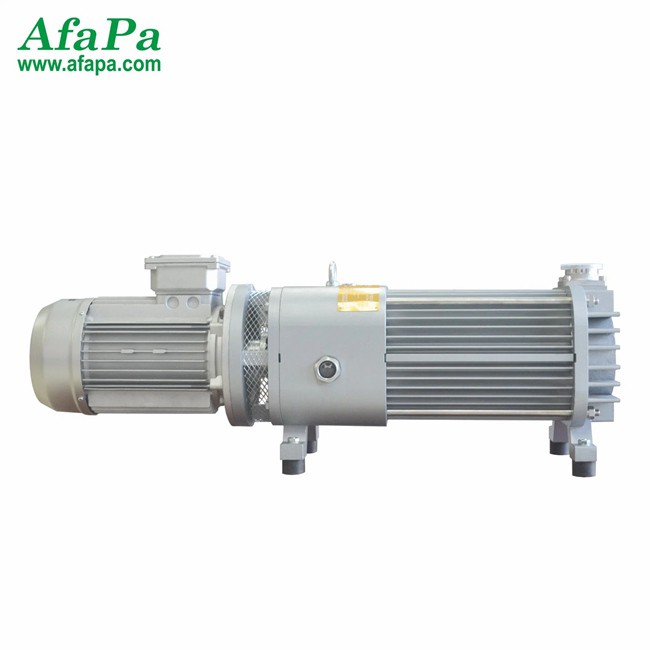

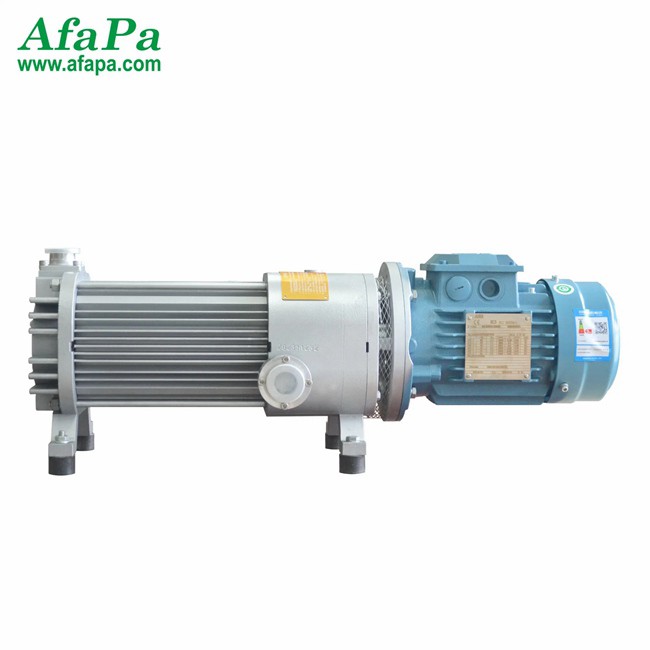

High Efficiency Vacuum Evaporating Using Water Ring Vacuum Pump for Lab Vacuum Distillation

Product Description

Oil free vacuum pumps draw air into the pump through specific mechanical structures such as molecular pumps, dry screw pumps, etc. Compress the gas inside the pump to reduce its volume and increase pressure. The compressed gas is discharged from the pump through the exhaust pipe to form a certain negative pressure, thereby achieving a vacuum effect. Oil free vacuum pump is an environmentally friendly, efficient, and reliable vacuum pump equipment widely used in multiple fields. During the selection and use process, it is necessary to pay attention to relevant matters to ensure its normal operation and extend its service life.

advantage:

The structure is simple and compact, with the characteristic of isothermal compression.

There is no metal friction surface inside the pump, with minimal wear and gas can be continuously and stably pumped out.

Not sensitive to dust and water vapor in the extracted gas.

Vacuum pumps are widely used in processes such as distillation, drying, degassing, concentration, and reaction in chemical production. For example, in the field of petrochemicals, vacuum pumps are used for crude oil distillation and refining; In organic synthesis, used for degassing operations; In the polymer industry, it is used for degassing and concentration in polymerization reactions. In the pharmaceutical production process, vacuum pumps are used for drying, concentrating, and extracting drugs to ensure the purity and quality of the products.

Turbovacuum pumps use the rotation of the turbine to extract gas. A limited working chamber is formed between the turbine and the pump chamber. When the turbine rotates, the gas in the working chamber is discharged and new gas is sucked in. Molecular sieve adsorption vacuum pump utilizes the adsorption effect of molecular sieve on gas to achieve suction. Molecular sieves have a highly porous structure and can selectively adsorb gas molecules. When the molecular sieve is saturated with adsorption, it is released by heating to restore its adsorption capacity.

Recommended Products

Recently Viewed

Contact Us

Shanghai Afapa Vacuum Technology Co., Ltd.