Welcome!

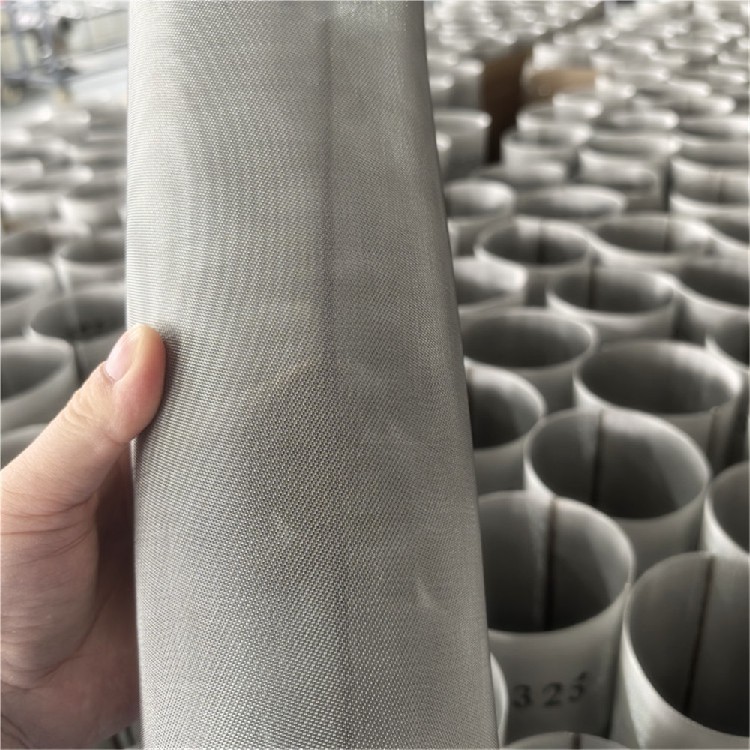

Factory Direct Sale Ultra Fine Stainless Steel Mesh Stainless Steel Mesh Cloth Micro Mesh Screen

Product Description

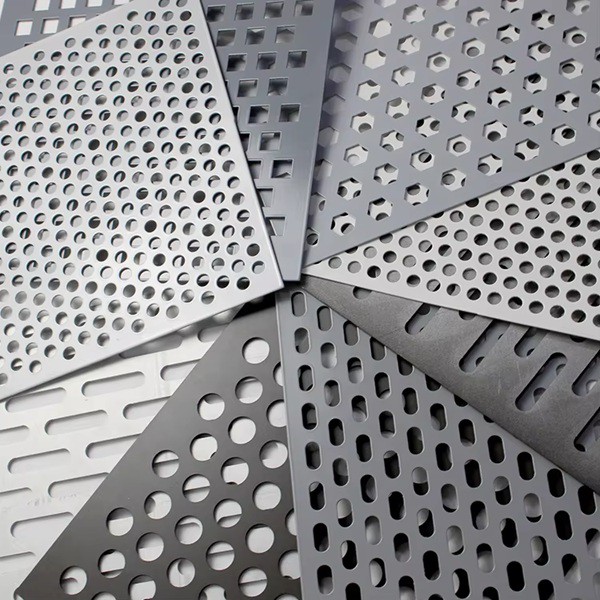

Stainless steel screen mesh has a tight structure, uniform mesh arrangement and smooth and flat surface. Its mesh shapes and sizes can be customized according to specific needs, such as square, rectangle, rhombus, round and so on. Different shapes and sizes of mesh are suitable for different screening and filtering needs. Meanwhile, the thickness of stainless steel screen mesh is also one of the important factors affecting its performance and service life, and the appropriate thickness is usually selected according to the actual needs.

In order to maintain the good performance and prolong the service life of stainless steel screen mesh, you need to regularly use water or mild detergent to clean the surface of the screen mesh to remove the attached dirt and impurities. For residues that are difficult to clean, a soft bristle brush or high-pressure water gun can be used. Regularly check the wear and tear of the screen mesh and whether the mesh holes are clogged. If any serious wear and tear or clogged mesh holes are found, the screen should be replaced or cleaned in time.

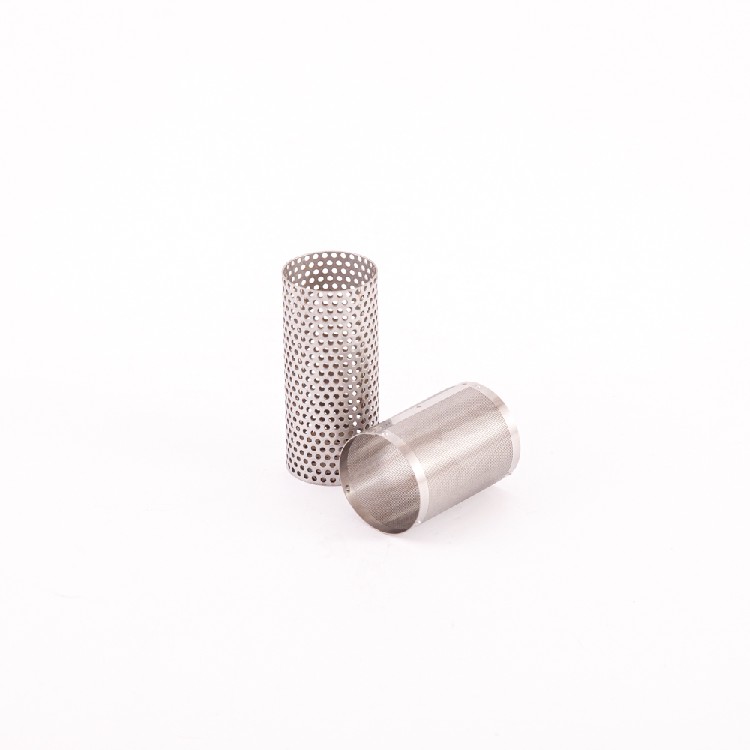

As an important filtration and separation equipment, sieve mesh is widely used in many fields, such as chemical industry, medicine, food and so on. Among them, ultrafine screens have become an indispensable tool due to their unique properties and wide range of applications. Ultrafine screens, as the name suggests, have extremely small sieve hole sizes, usually reaching micron level (e.g. 1μm). This fine screening capability gives ultrafine screens a significant advantage in material separation and filtration. Its main features include:

Ultra-fine sieve mesh can effectively separate out the fine particles in the material to ensure the purity and uniformity of the product. High temperature resistance, acid and alkali resistance: many ultra-fine screens are made of stainless steel, which has excellent high temperature resistance, acid and alkali resistance, and can operate stably in harsh working environments. High-quality stainless steel wires are woven into the screen mesh, which has good abrasion resistance and prolongs the service life. According to the customer's demand, we can customize the screen mesh with different sizes, hole types and precision to meet the diversified production needs.

As one of the important equipments in modern industrial production, ultrafine screen plays an important role in many fields with its features of high precision screening, high temperature resistance, acid and alkali resistance, and good abrasion resistance. With the continuous development of material science and manufacturing process, ultrafine screen technology will usher in a broader development prospect. In the future, we expect to see more innovative technology applications and further enhancement of screen performance, injecting new vitality into the production activities of various industries.

Recommended Products

Recently Viewed

Contact Us

Hebei Aegis Metal Materials Co., Ltd.