Welcome!

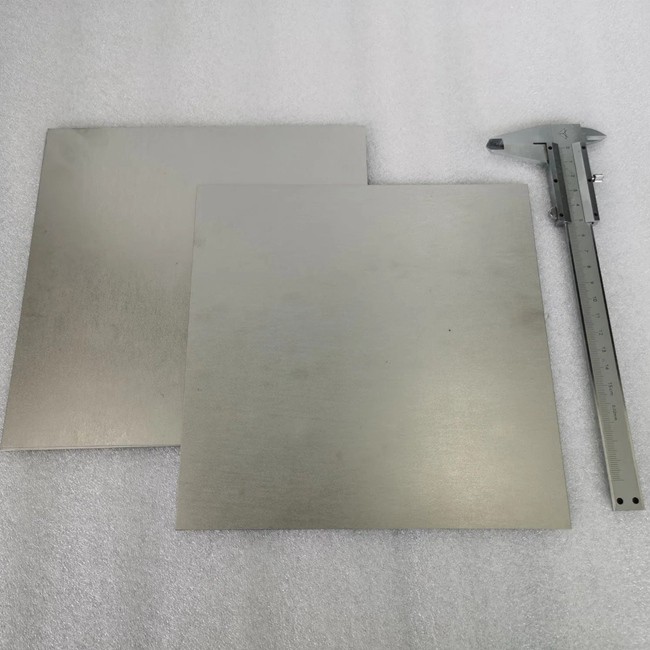

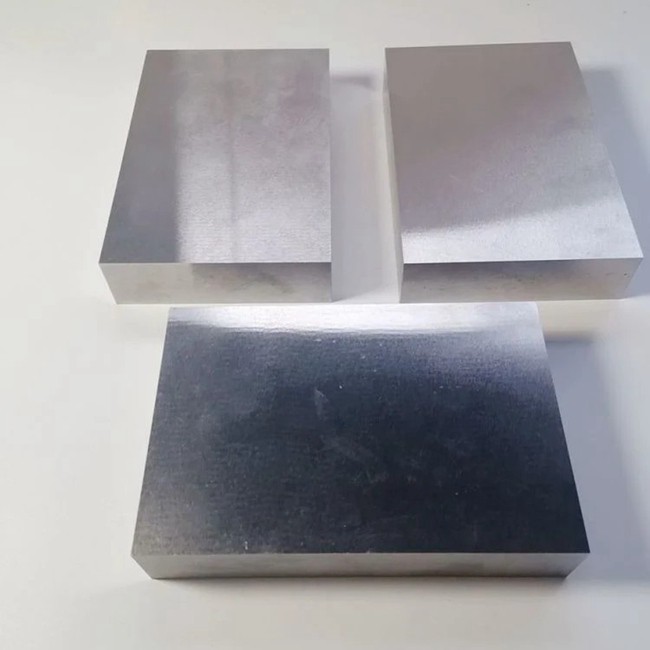

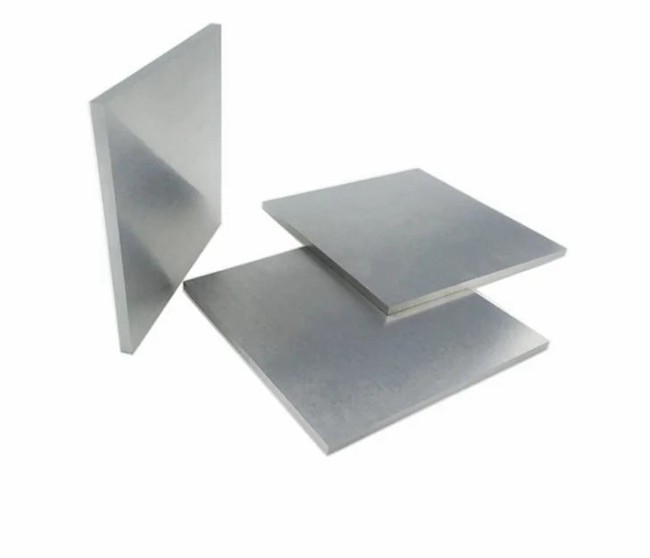

Factory Made Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Mold Making

Product Description

Tungsten sheet is a type of plate made from tungsten metal with a unique set of physical and chemical properties. Tungsten sheet is a metal material with unique physical and chemical properties that plays an important role in many fields. With the continuous progress of science and technology and the continuous improvement of process, the application fields of tungsten plate will be further expanded and the market demand will continue to grow.

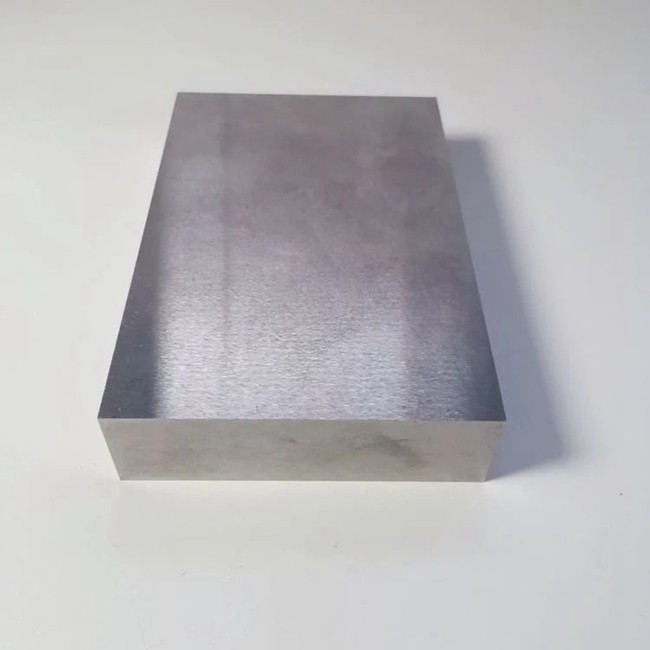

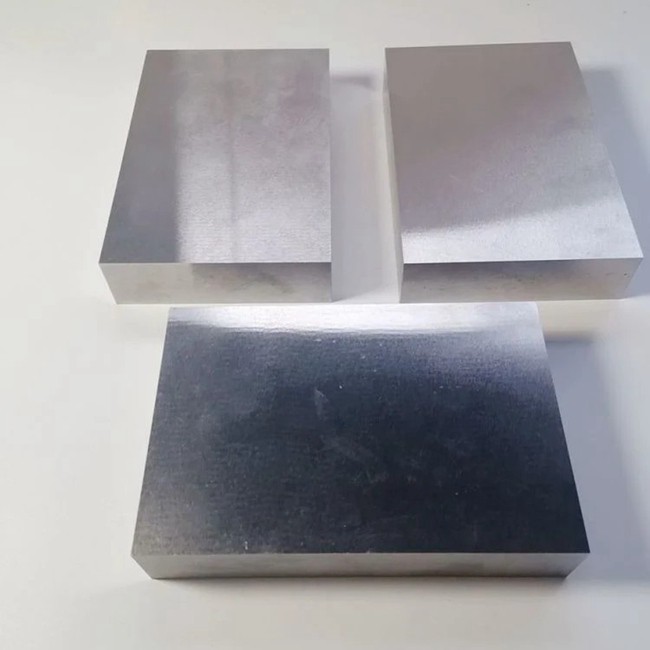

Tungsten alloy plates also have good mechanical properties, including high strength, high hardness and good wear resistance. These properties make tungsten alloy plates widely used in machining, mold making and other fields, and can withstand high loads and high abrasion working environments. Tungsten alloy plates also have excellent thermal stability and corrosion resistance. The high melting point of tungsten allows the alloy plate to maintain good performance in high temperature environments, while its resistance to a wide range of chemicals allows it to work in harsh chemical environments, such as applications in chemical equipment and nuclear energy facilities.

The melting point of tungsten is as high as 3422 degrees Celsius, which is the highest among all metals. As a result, tungsten alloy sheet excels in high-temperature environments and can withstand extreme thermal stability requirements, making it an ideal material for high-temperature applications such as aerospace and nuclear energy. Tungsten alloy sheet is resistant to a wide range of chemicals, including acid and alkali solutions, oxides and salt solutions. Its good chemical stability and corrosion resistance make it widely used in chemical, semiconductor and electronic fields for manufacturing equipment and components with high corrosion resistance requirements.

The density of tungsten alloy plate is extremely high, generally between 16.5~19.0g/cm³, which is equivalent to more than twice the density of steel. This characteristic gives it excellent tensile strength and compression resistance. The tensile strength of W-Ni-Fe high-density alloy in sintered state can be up to 800~1000MPa, and the strength can be further increased to 1300~1500MPa after heat treatment and deformation processing.

Recommended Products

Recently Viewed

Factory Made Tungsten Carbide Wear Parts Tungsten Carbide Plate for Making Industry Cutting Tools

Factory Made Tungsten Carbide Wear Parts Tungsten Carbide Plate for Making Industry Cutting Tools Factory Custom Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools

Factory Custom Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools Factory Made Carbide Sheet Tungsten Steel Plate for Mold Making

Factory Made Carbide Sheet Tungsten Steel Plate for Mold Making 100% Virgin Material Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools

100% Virgin Material Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools Factory Custom Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools

Factory Custom Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools

Contact Us

Jiangsu Xinmechan Technology Co., Ltd.