Welcome!

cheap price light weight UV resistant waterproofing breathable membrane

- T/T D/P D/A MoneyGram Credit Card

- Shanghai

- 60000 Square Meter / Square Meters per Month

Basic Info

| Brand Name | KangDa | Model Number | KDBG110 | Place of Origin | Jiangsu, China |

|---|

Product Description

Product Description

Water vapour Permeable Breather membrane used for pitched roofing underlayment or steel construction

Feature: Good tearing strength, waterproof, good breathability, soft handle, heat insulation

Excellent performance of breather membrane allows vapour to pass through while keep water or rain outside, it can keep the construction structure dry and long term usage.

Constructed from high tensile spun-bonded polypropylene layers

Highest levels of water resistance

Full moisture vapour permeability

Breathable underlay for tiled and slated pitched roofs

Eco-friendly to be completely recyclable

UV resistant

Others as buyers requirements

Width: 100cm, 150cm

Weight: 90GSM

Length: 50M, 100M

Hydrostatic head (pa): >2000

Tensile Strength (N): 120(CD) 180(MD)

Elongation (N): 150(CD) 150(MD)

Water-vapor Permeability: >2000G/M2:

Annual output: 2500ton

<![if !vml]><![endif]><![if !vml]><![endif]>

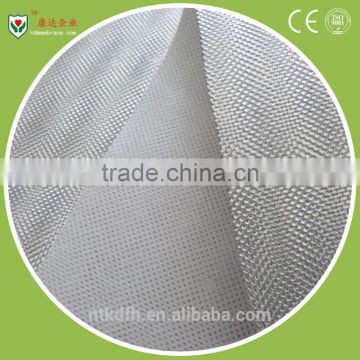

3 layer waterproofing breathable roofing membrane

Material: A three layer highly breathable, fully waterproof membrane, constructed from high

tensile spunbonded polypropylene layers, combined with a microporous polypropylene film. The outer

layer forms the functional waterproof surface; the middle layer is the breathable waterproof

membrane and the inner layer protects the membrane from abrasion and damage, also

giving additional strength. Such structure enables the fabric to allow moisture vapour to pass through,

whilst remaining fully waterproof. We can provide various colors on upper surface, printed with

the customer’s logo and head lap lines.

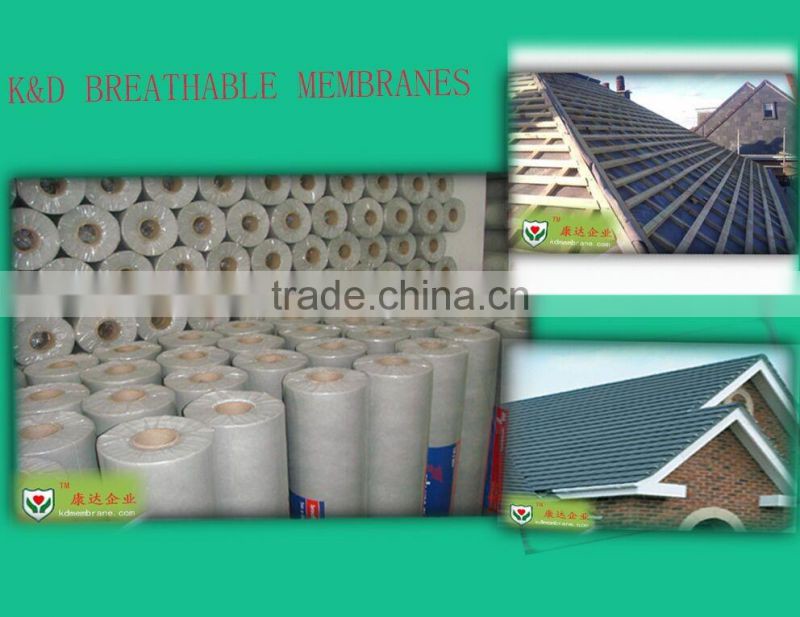

Use: Breathable roofing underlay positioned immediately above the insulation layer in a warm

pitched roof, or in a cold pitched roof (ventilated or unventilated). Breathable roofing underlay

for use under tiles and sheeted roofs, over open rafters or on to fully boarded substrates

Breather membrane for timber frame wall construction

About Breathable membrane Application:

Breathable membrane mainly for used as pitched roofing underlay for European customers, and mainly used for house wrap or wall wrap for America customers, as for our China mainland customer, the breathable membrane is used for steel construction. After years of deverlopment, we have reached out different ways to produce different breathbility membranes, which will sastisfy different customer's requirements.

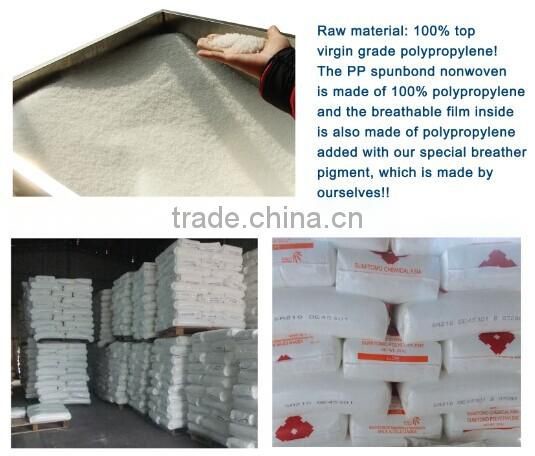

Raw material:

Raw material: 100% top virgin grade polypropylene! The PP spunbond nonwoven is made of 100% polypropylene, and the breathable film inside is also made of polypropylene, added with our special breather pigment, which is made by ourselves!!

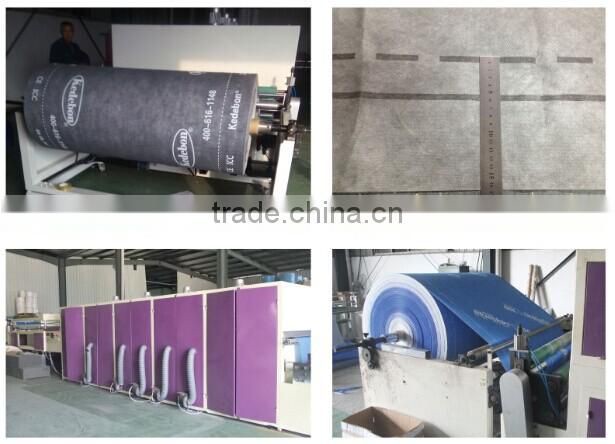

Printing and Slitting:

As a OEM factory, we would like to make customer's logo on the breathable membrane. Our company now have 3 printing lines, two of which are silk-screen printing. The silk-screen printing makes the logo very clear, any kind of color is acceptable; the shortcoming is the low speed of production, higher cost. and only one color logo is available.

Packing and Delivery:

Packing: Normally is free PE wrap, with two inches paper core inside. Our new shrink film packing machine will be added by the end of this year. Free loading and pallet packing loading are both OK. Customer specialized label is available.

Testing:

Our lab is certified by National Certification Department.

Exhibition:

Batimat show in Paris!

International Builder's Show in Las Vegas!

Contact:

Recommended Products

Recently Viewed

Contact Us

Nantong Kangda Complex Material Co., Ltd.