Welcome!

2014 high sales chicken layer farm

- T/T MoneyGram Credit Card

- Qingdao

- 10000 Set / Sets per Month

Basic Info

| Brand Name | XGZ | Material | Hot galvanizing steel | Model Number | QDXR14CH-01 . |

|---|---|---|---|---|---|

| Place of Origin | Shandong, China | Use | Chicken | ||

Product Description

Product Description

Specifications

1. A type chicken cages

2.20 years no rustiness

3.perfect temperature control

4.original design,OEM

5.poutltry house

Broiler layout farm

Please Supply your poultry house size orchicken raising quantity, Our engineers will supply you the suitable, economical and efficient design.

Our broiler chicken farm Project pictures

Sample of Specification of Broiler Chicken and Egg Laying Chicken Cage System

The followed details are recommended, welcome your request and own design, our Professional research and development group will deal with it seriously for your birds laying and feeding.

Item | Broiler Cage | Egg Laying Chicken Cage |

3-tier /2-door | 3-tier /5-door | |

Set capacity | 120 birds | 120 birds |

Cell capacity | 10 birds | 4 birds |

Cage size | 5.25 by 6.89 by 5.4 feet | 7.2 by 7.9 by 5.0 feet |

Cell size | 31.5 by 13.8 by 16.54 inch | 16.9 by 16.6 by 16.5inch |

Fittings | Cages, cage frame, water pipe, drinkers, feeders, other necessary fittings Drinking system is automatic, after installation then put birds and food | |

Materials | Q195 steel wire , Q235 steel wire | |

Recommended Sets/Row | 10 sets to 55 sets | |

Lifespan | 5 years to 30 years as different countries' climate and poultry house design | |

Accessories Of automatic cages for chickens

Cage mesh | wire diameter from 2.0mm to 4.0mm cold galvanized or hot deep galvanized |

Cage frame | Angle bar frame and U- type steel frame |

Feeding trough | 1) 80*90*110mm 2) 70*80*120mm 3) 70*80*90mm The loading capacity of each layer of one Group: 60KG/PC Above Size is as to different usage, different quality. |

Water pressure controlling system | Supply cleaning and average fresh water for each chicken |

Drinkers | Stainless steel nipple drinkers Warranty of best quality is 15 years |

Automatic cages for chickens Wire Mesh Welding Process

Hard-drawn wire, Straightening wire, Molding Process, Row welding, Spot welding, Cutting Process,

Shaping Process, Galvanizing Process.

Regular common cage mesh panel is made by Automatic welding machines.

Irregular cage mesh panel is made irregular by manual welding.

Chicken Trolley Feeding Equipment ( Automatic or Semi Automatic )

For A type or H type Cage System - The unique choice of your large-scale layer chicken farms

Excellent Structure

Strong structure design, working stability, low noise, heavy load capability and high efficiency in conveying

Reposeful Walking system

Excellent shock resistance performance,chain transmission,Travelling wheel and hopper frame are fused together,walking Steadily,corrosion resisting

Well balanced Feed output system

Manufacture Process: Made by professional mold under numerically-controlled machine tool

Feed output: feed regulator control well-proportioned Feed output

The output rate: 1.25kg-5.85kg/12m/Min by adjusting the speed motor

Automatic Poultry Farm Egg Collecting Equipment

For A type or H type cage system - the unique choice of your large-scale layer chicken farms

Major Accessories

Front-end Egg-collection Machine

Soft Egg Sorting Equipment

Egg Conveyor Belt

Terminal Equipment

Transverse Central Egg-collection System

Advantage

Eggs are sent to the same egg storage house from all chicken house by connection of Front-end Egg-collection Machine and Transverse Central Egg-collection System

Reduce the egg damaging rate lower than 0.50%

Save labor force, Improving farm’s economical efficiency

Egg Conveyor Belt is imported from Italy under EU product quality standard

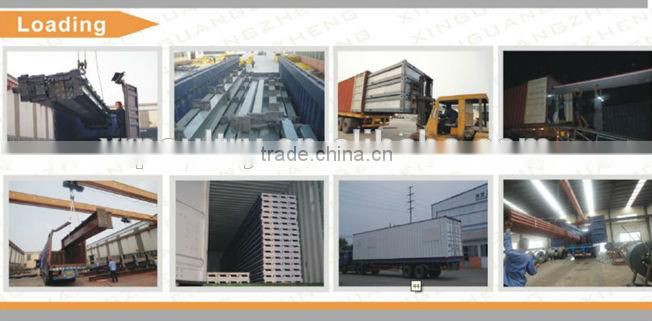

Package:

Packed by PVC Strip and plastic foam.

Loaded in sea freight container or per requests.

Loading:

20 GP,40 GP

Port:

Qingdao port, China.

one-stop service:

We supply the technical supportabout building and maintenance of steel structure poultry house.

We also can provide the model plan , if you tell us the information as bellow:

Factory address:

No.268,Sancheng road , Pingdu, Qingdao, China

Contract person: Kerwin Xu

Tel: +86 18560455549

As one of the leading poultry farm manufactures, our workshop area covers advanced processing equipment, good technological innovative ability, great capacity of production and processing in China. We also have established a good cooperative relationship with many worldwide companies. Our company has passed ISO9001:2008, TUV Rhineland authentication.

Recommended Products

Recently Viewed

Contact Us

Qingdao Xinri Poultry Machine Manufacturing Co., Ltd.