Welcome!

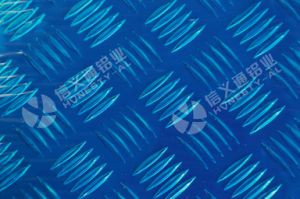

Wholesale Anti-Corrosion Aluminum Foil Aluminum Coil Aluminum Strip with Coating

Product Description

7075 mainly contains zinc. It also belongs to the aviation series. It is an aluminum magnesium zinc copper alloy, a heat-treatable alloy, a super-hard aluminum alloy, and has good wear resistance. The 7075 aluminum plate is stress-relieved, and will not deform and warp after processing. All the super-large and super-thick 7075 aluminum plates are subject to ultrasonic detection, which can ensure that there are no sand holes and impurities. 7075 is an aluminum alloy with high hardness and strength, which is often used to manufacture aircraft structures and futures. It requires the manufacture of high stress structural parts and moulds with high strength and strong corrosion resistance. Basically relying on imports, China's production technology needs to be improved.

The aluminum alloy with silicon content between 8% and 12% is a transition zone, which can use both ordinary cemented carbide and diamond tools. However, when using cemented carbide, tools with PVD (physical coating) method, no aluminum element and smaller film thickness shall be used. Because the PVD method and small film thickness make it possible for the tool to maintain a sharp cutting edge (otherwise, to avoid the abnormal growth of the film at the edge, it is necessary to passivate the edge sufficiently, and the cutting aluminum alloy will not be sharp enough), and the film material containing aluminum may cause the affinity between the blade film and the workpiece material and damage the combination of the film and the tool substrate. Because the superhard coating is mostly composed of aluminum, nitrogen and titanium, the edge may be broken due to a small amount of peeling off of the cemented carbide substrate along with the film.

Recommended Products

Recently Viewed

China Factory Supply ultra aluminum fence Garden/Field/Farm Fence

China Factory Supply ultra aluminum fence Garden/Field/Farm Fence Good Price ultra aluminum fence Aluminium Fence for Privacy

Good Price ultra aluminum fence Aluminium Fence for Privacy High Quality elite aluminum fence Garden/Field/Farm Fence

High Quality elite aluminum fence Garden/Field/Farm Fence High Quality powder coated aluminum fence Aluminium Fence for Privacy

High Quality powder coated aluminum fence Aluminium Fence for Privacy Good Price aluminum fence vs steel Aluminium Fence for Privacy

Good Price aluminum fence vs steel Aluminium Fence for Privacy

Contact Us

Jinan Honesty Aluminum Industry Co., Ltd.