Welcome!

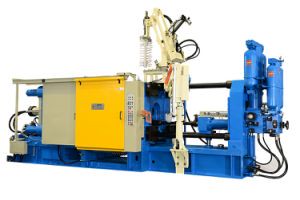

New Green Cold Chamber Aluminum High Pressure Copper Die Casting Machine

Product Description

Foundry machinery is generally classified according to molding methods, and is customarily divided into ordinary sand casting and special casting. Common sand mold casting includes three types: wet sand mold, dry sand mold, and chemical hardening sand mold casting. According to the different molding materials, special casting can be divided into two categories: one category uses natural mineral sand as the main molding material, such as investment casting, shell mold casting, negative pressure casting, mud mold casting, full mold casting, ceramic mold casting, etc; One type uses metal as the main casting material, such as metal mold casting, centrifugal casting, continuous casting, pressure casting, low pressure casting, etc.

Post treatment of castings: The process of performing heat treatment, shaping, rust prevention treatment, and rough machining on cleaned castings. Post treatment of castings is the last step in the production of casting equipment. The process of removing a casting from a mold, removing excess parts outside the body, and polishing and finishing the inner and outer surfaces of the casting equipment. The main work is to clean the mold core and core iron. Cast Nonferrous Alloys Nonferrous alloys used to cast castings are a class of casting equipment. There are mainly cast copper alloys, cast aluminum alloys, and cast magnesium alloys.

Recommended Products

Recently Viewed

Customized Wire Straightening Tool with 18 Rollers Copper Wire Straightener

Customized Wire Straightening Tool with 18 Rollers Copper Wire Straightener Wholesale Wire Straightening Tool with 18 Rollers Copper Wire Straightener

Wholesale Wire Straightening Tool with 18 Rollers Copper Wire Straightener Factory Directly Wire Straighteners for Drawing Lines Steel Wire Straightening Machine

Factory Directly Wire Straighteners for Drawing Lines Steel Wire Straightening Machine Wholesale Wire Forming Machine Metal Straightening Machinery Steel Straightener

Wholesale Wire Forming Machine Metal Straightening Machinery Steel Straightener High Quality Wire Forming Machine Metal Straightening Machinery Steel Straightener

High Quality Wire Forming Machine Metal Straightening Machinery Steel Straightener

Contact Us

Jiangmen Zhenli Machinery Co., Ltd.