Welcome!

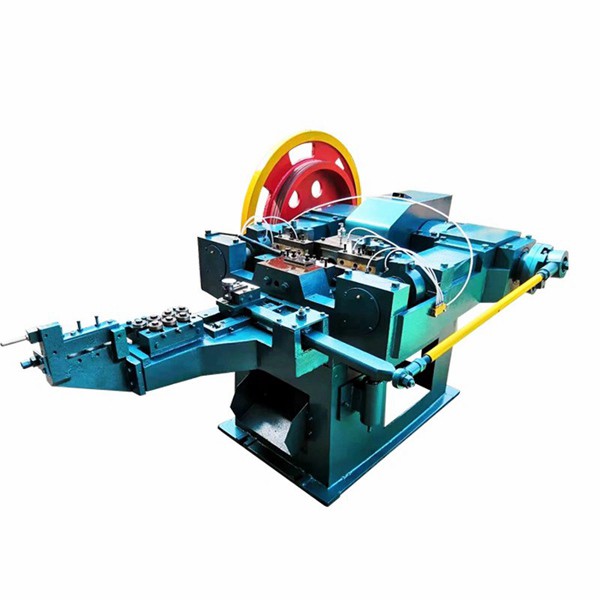

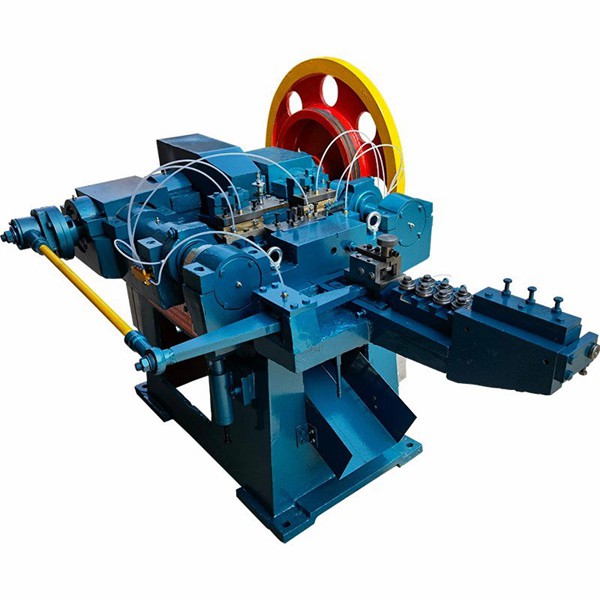

Automatic Iron Wire Nail Steel Nail Manufacturing Machine Suppliers

Product Description

The steel nail manufacturing machine adopts an automated production process, which can continuously produce and greatly improve production efficiency. Through precise control systems and mechanical structures, the steel nail manufacturing machine can ensure the accurate size and stable quality of the produced steel nails. The steel nail manufacturing machine can adjust production parameters as needed to adapt to different specifications and types of steel nail production. Equipment is usually equipped with comprehensive safety protection devices to ensure the safety of operators.

High speed nail making machines are widely used in industries such as construction, furniture manufacturing, and packaging, especially in situations where a large and fast production of nails is required, such as construction sites and furniture factories. High speed nail making machines will develop towards a more intelligent and automated direction, while focusing on energy conservation, emission reduction, and environmental performance improvement. The high-speed nail making machine ensures the accurate size and stable quality of the produced nails through precise control systems and mechanical structures. It can produce various nails with diameters ranging from 2.0mm to 3.5mm and lengths ranging from 45mm to 90mm.

The working principle of a high-speed nail making machine mainly includes steps such as wire feeding, cutting, welding, positioning, forming, and removal. The steel wire is fed into the machine through the feeding system, and after precise cutting and welding, the steel wire is positioned and shaped into the required nail shape. Finally, it is automatically removed by the hook head to complete the production of the nail. The high-speed nail making machine is suitable for producing various types of nails, such as roll nails, paper row nails, core pulling rivets, large and small cap nails, etc., and has strong adaptability.

As an important equipment for nail production, nail making machines play an irreplaceable role in fields such as metal processing, construction, and furniture manufacturing due to their high efficiency and precision. As an important equipment in modern industry, nail making machines play an important role in various fields due to their high efficiency and precision. With the continuous progress of technology and the expansion of application fields, the development prospects of nail making machines will be even broader.

The nail making machine mainly consists of a feeding system, a stamping system, a cutting system, and a control system. Its working principle is to feed raw materials into the stamping area through a feeding system, undergo a series of precision stamping and cutting operations, and finally produce nails that meet the requirements. Throughout the process, the control system plays a crucial role in ensuring stable and efficient production of the machine according to preset parameters.

Recommended Products

Recently Viewed

Customized Wire Straightening Tool with 18 Rollers Copper Wire Straightener

Customized Wire Straightening Tool with 18 Rollers Copper Wire Straightener Wholesale Wire Straightening Tool with 18 Rollers Copper Wire Straightener

Wholesale Wire Straightening Tool with 18 Rollers Copper Wire Straightener Factory Directly Wire Straighteners for Drawing Lines Steel Wire Straightening Machine

Factory Directly Wire Straighteners for Drawing Lines Steel Wire Straightening Machine Wholesale Wire Forming Machine Metal Straightening Machinery Steel Straightener

Wholesale Wire Forming Machine Metal Straightening Machinery Steel Straightener High Quality Wire Forming Machine Metal Straightening Machinery Steel Straightener

High Quality Wire Forming Machine Metal Straightening Machinery Steel Straightener

Contact Us

WuXi JingJie Robot Technology Co., Ltd.