Welcome!

New Design Computerized Lockstitch Sewing Machine

Product Description

Computer controlled sewing machines perform well in terms of automation, precision, multifunctionality, ease of operation, low noise and vibration, and cleanliness and environmental protection. It is one of the essential high-precision equipment in modern sewing industry, widely used and favored by various industries. With the continuous advancement of technology and changes in market demand, the performance and functionality of computerized sewing machines will continue to improve and perfect.

Industrial sewing machines have also promoted the upgrading and transformation of the entire industry chain. With the popularization and application of automation and intelligent technology, the textile and garment industry is gradually developing towards digitalization, networking, and intelligence, injecting new vitality into the sustainable development of the industry. As the core production equipment in the textile and garment industry, industrial sewing machines play an important role in promoting industry progress and upgrading. With the continuous advancement of technology and changing market demands, we have reason to believe that industrial sewing machines will play a more important role and contribute in the future.

On the vast stage of the textile and garment industry, industrial sewing machines, as the core production equipment, continue to drive the progress and development of the industry with their efficient, precise, and diversified sewing capabilities. Flat sewing machine is the most common type of industrial sewing machine used for sewing straight and simple curves, widely used in clothing, luggage, footwear and other fields.

Industrial sewing machines, as the name suggests, are sewing equipment designed specifically for large-scale production. Compared to household sewing machines, they have more powerful motors, stronger bodies, more complex mechanical structures, and higher sewing speeds. These characteristics enable industrial sewing machines to work continuously, efficiently complete a large number of sewing tasks, while ensuring the firmness and aesthetics of the stitches.

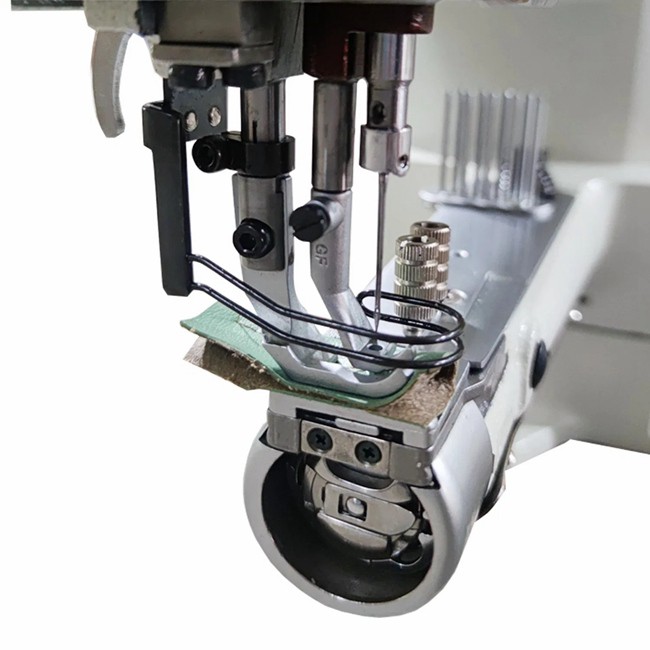

The working principle of a sewing machine mainly includes four steps: thread transfer, pinhole formation, stitch formation, and fabric transfer. The sewing machine provides two threads, upper and lower, through a spool, which enter the machine body through a guide, tensioner, and spool to ensure smooth thread transfer. The sewing machine forms needle holes through the reciprocating motion of the upper and lower needles. When the needle moves downwards, the upper needle passes the thread through the fabric through the thread plate and the lower needle eye plate, forming a needle eye. The formation of a trace depends on the interweaving of online and offline lines. When the upper needle passes down through the fabric, it will thread the upper thread through the fabric and interweave with the lower thread in the needle eye, forming a stitch. The sewing machine transfers fabric through the lower hem, upper hem, and gear transmission. When the gear rotates, the lower swing and upper swing move alternately, conveying the fabric forward.

Recommended Products

Recently Viewed

Factory Supplier Direct Drive Computerized Lockstitch Industrial Sewing Machine

Factory Supplier Direct Drive Computerized Lockstitch Industrial Sewing Machine High Speed Direct Drive Direct Drive Computerized Lockstitch Industrial Sewing Machine

High Speed Direct Drive Direct Drive Computerized Lockstitch Industrial Sewing Machine New Design Touch Panel Computerized Lockstitch Sewing Machine with Speaking

New Design Touch Panel Computerized Lockstitch Sewing Machine with Speaking High Quality Industrial Direct Drive Auto Trimmer Sewing Machine

High Quality Industrial Direct Drive Auto Trimmer Sewing Machine High Speed Direct Drive Computerized Lockstitch Sewing Machine

High Speed Direct Drive Computerized Lockstitch Sewing Machine

Contact Us

KUN SHAN EAGLE TECHNOLOGY CO.,LTD.