Welcome!

High Quality Profile Trapezoidal Tile Metal Roofing Sheet Roll Forming Making Machine

Product Description

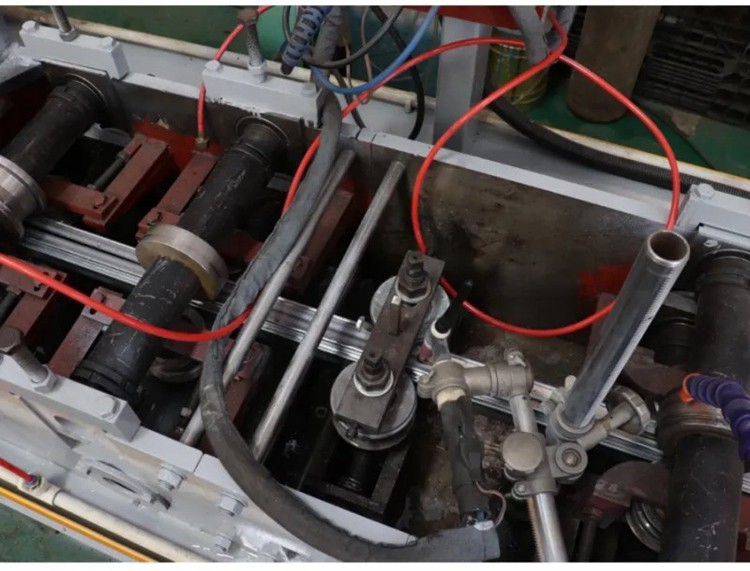

In order to enhance the wind resistance and appearance of the tiles, the forming part also includes a embossing device. By heating, cooling, and applying pressure, certain protrusions are formed on the surface of the tiles to improve overall performance. Finally, the formed tiles are cut to a predetermined length using hydraulic or mechanical cutting mechanisms, completing the entire production process.

Advantages and Characteristics

Efficiency: The cold tile forming machine can continuously and automatically complete processing tasks, greatly improving production efficiency.

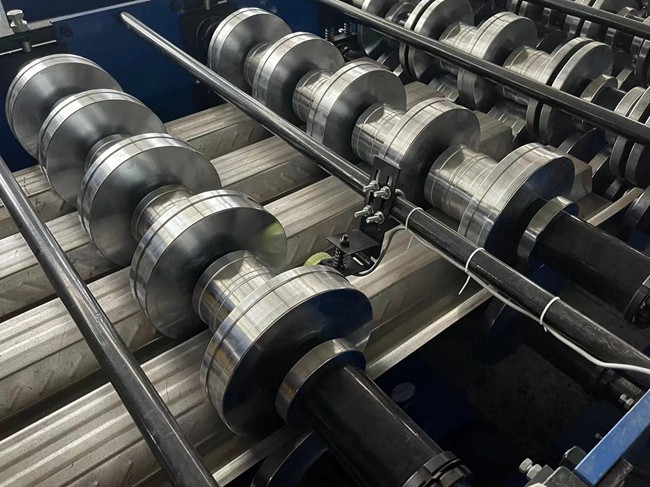

High precision: Through precise roller and mold design, it can ensure that the processed products have extremely high dimensional and shape accuracy.

Flexibility: The equipment can adjust and replace molds according to different processing needs, thus adapting to processing tasks of various specifications and shapes.

Economy: Cold bending technology has lower energy consumption and less material waste compared to hot processing, therefore it has higher economic benefits.

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.