Welcome!

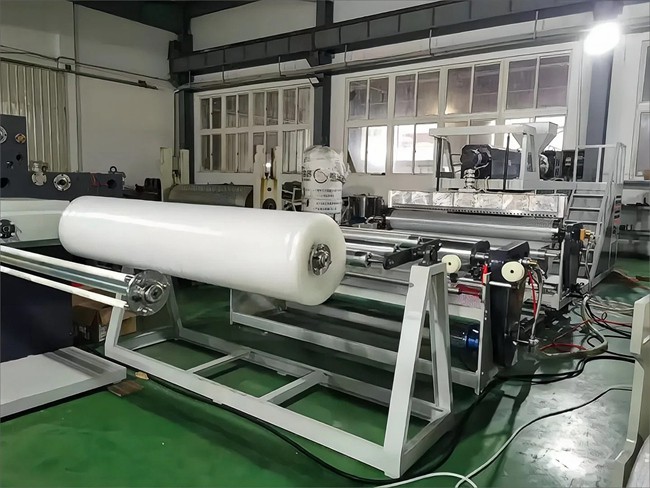

High Speed Plastic Garbage Flat Bag Cutting Making Machine

Product Description

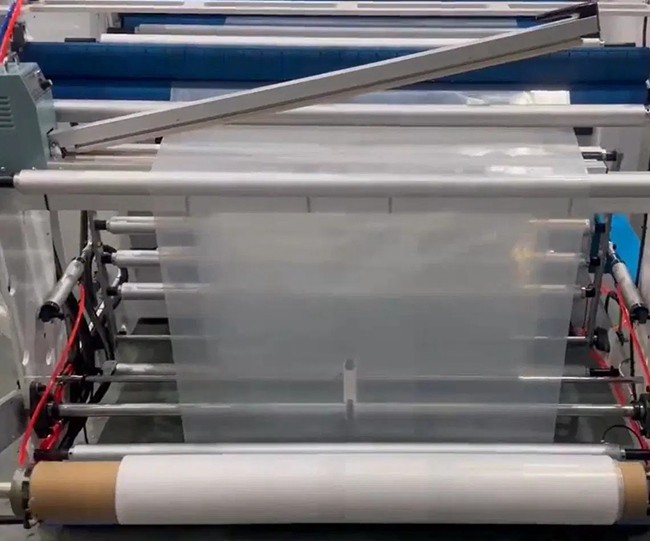

If the product design has printing content, the printing process should be carried out before the plastic film cools down. After printing is completed, the plastic film is rolled into large rolls and then cut by a bag making machine. The bag making machine divides the roll plastic film into individual garbage bag products according to the set length and shape. Different product forms (such as flat rolled bags, vest style rolled bags, etc.) have different cutting methods.

In the machine, polyethylene particles are heated to a molten state and enter the bag making machine through specific pipes. The melted plastic is formed into a continuous plastic film through the blown film process, and when the film width and length meet the design standards, it is cooled and shaped.

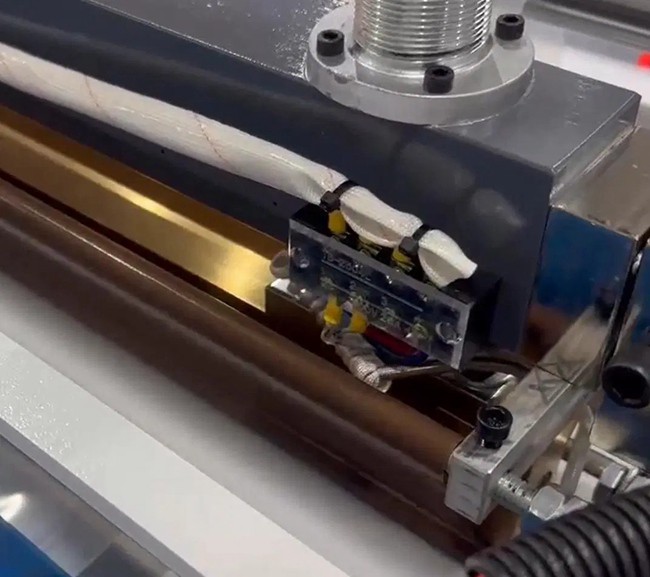

Garbage bag manufacturing machine is a production equipment that integrates automation and efficiency. It mainly consists of a material storage device, a stepper device, a frequency conversion device, a whole bag device, a heat sealing cutter, and a control device. These components work together to complete the entire process from raw material transportation to finished product production. The garbage bag manufacturing machine also pays attention to energy conservation and emission reduction in the production process. By optimizing equipment structure and improving production efficiency, reducing energy consumption and waste emissions, we contribute to the cause of environmental protection.

With the acceleration of urbanization, garbage disposal has become an important part of urban management. Garbage bags, as an indispensable item in daily life, are receiving increasing attention for their production efficiency and environmental performance. As an important equipment in this field, the garbage bag manufacturing machine not only improves production efficiency, but also continuously promotes the development of environmentally friendly production through technological innovation.

Recommended Products

Recently Viewed

High Quality Three Layers PE Air Bubble Film Extruder Machine

High Quality Three Layers PE Air Bubble Film Extruder Machine High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine

High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine High Speed 3-7 Layers Composite Air Bubble Film Making Machine

High Speed 3-7 Layers Composite Air Bubble Film Making Machine High Quality 3-7 Layers Composite Air Bubble Film Making Machine

High Quality 3-7 Layers Composite Air Bubble Film Making Machine Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Contact Us

WENZHOU E-SHION MACHINERY CO., LTD.