Welcome!

High-Quality High-Performance Polythene Garbage Bag Making Machinery

Product Description

As an important equipment for modern environmentally friendly production, the garbage bag manufacturing machine not only improves production efficiency and product quality, but also promotes the development of environmentally friendly production. With the continuous advancement of technology and the improvement of environmental awareness, we believe that garbage bag manufacturing machines will play a more important role in the future, bringing more convenience and beauty to our living environment.

The cut garbage bags need to be punched and sealed. Advanced robotic punching equipment creates easy-to-use pockets on garbage bags based on design and requirements. Subsequently, efficient machines seal the bottom of the bag to prevent garbage from leaking out. After sealing, the garbage bag is checked by testing equipment to see if it meets the standards. Qualified garbage bags are sent to the packaging machine for centralized packaging, and finally sealed in smooth plastic bags with relevant labels printed, ready for sale.

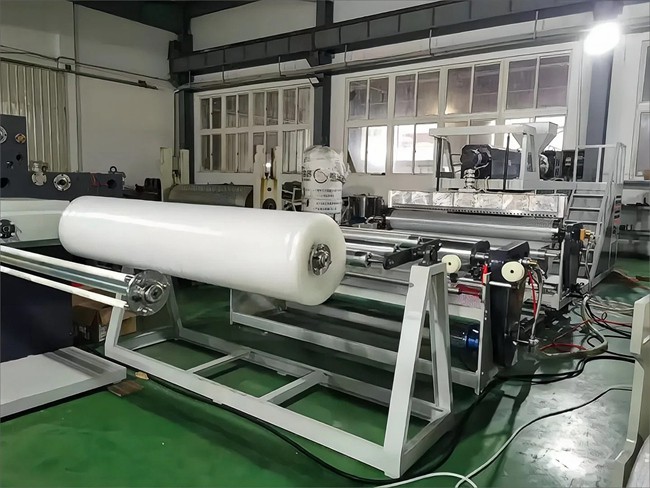

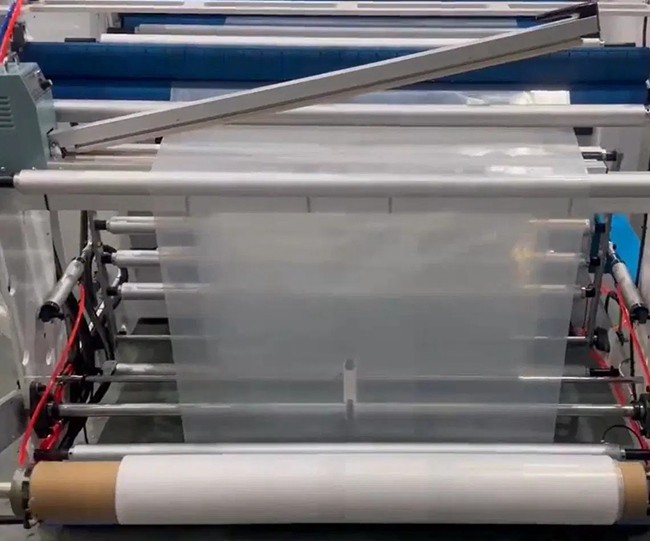

In the machine, polyethylene particles are heated to a molten state and enter the bag making machine through specific pipes. The melted plastic is formed into a continuous plastic film through the blown film process, and when the film width and length meet the design standards, it is cooled and shaped.

The heat sealing cutter is one of the core components of the garbage bag manufacturing machine, which precisely controls the temperature through a thermostat to seal and cut the plastic film. The whole bag device is responsible for processing the entire bag after producing a fixed number of bags, ensuring the consistency and stability of the product. The temperature controller adopts Delta DTA4848R with self-tuning function, with temperature error controlled within 0.1 degrees, ensuring precise sealing and cutting quality. The main raw material for producing garbage bags is polyethylene particles. These particles are formulated from high molecular weight polymers such as high-density polyethylene or low-density polyethylene, as well as other auxiliary materials such as fillers, plasticizers, lubricants, stabilizers, colorants, etc. These materials are mixed in specific proportions to ensure the overall performance of the garbage bag is good.

The storage device is responsible for storing and quantitatively supplying raw materials. Usually, the main raw material for producing garbage bags is polyethylene (PE) particles, which are heated and melted by specific machines before entering the subsequent production process. The storage device ensures accurate supply of raw materials through photoelectric control, providing stable raw material supply for continuous production. The stepper device drives the raw materials into the processing area, while the frequency converter controls the operating speed of key components such as the heat sealing cutter. The frequency conversion device adopts advanced Delta M-series frequency converters, which have functions such as automatic torque compensation, slip compensation, and automatic voltage stabilization, effectively protecting the motor, avoiding the impact of starting current on the power grid, and achieving energy conservation and consumption reduction.

Recommended Products

Recently Viewed

Factory Outlet Durable Plastic Chair Injection Moulding Machine

Factory Outlet Durable Plastic Chair Injection Moulding Machine Factory Outlet Toy Making Price Plastic Chair Injection Moulding Machine

Factory Outlet Toy Making Price Plastic Chair Injection Moulding Machine Factory Outlet Durable Plastic Chair Injection Moulding Machine

Factory Outlet Durable Plastic Chair Injection Moulding Machine Factory Outlet Plastic Chair Injection Moulding Machine Big Size Plastic Injection Molding Machine

Factory Outlet Plastic Chair Injection Moulding Machine Big Size Plastic Injection Molding Machine Automatic Plastic Chair Injection Moulding Machine Big Size Plastic Injection Molding Machine

Automatic Plastic Chair Injection Moulding Machine Big Size Plastic Injection Molding Machine

Contact Us

WENZHOU E-SHION MACHINERY CO., LTD.