Welcome!

Wholesale Wall Cladding Double Layer Steel Profile Zinc Metal Roofing Roof Glazed Tile Press

Product Description

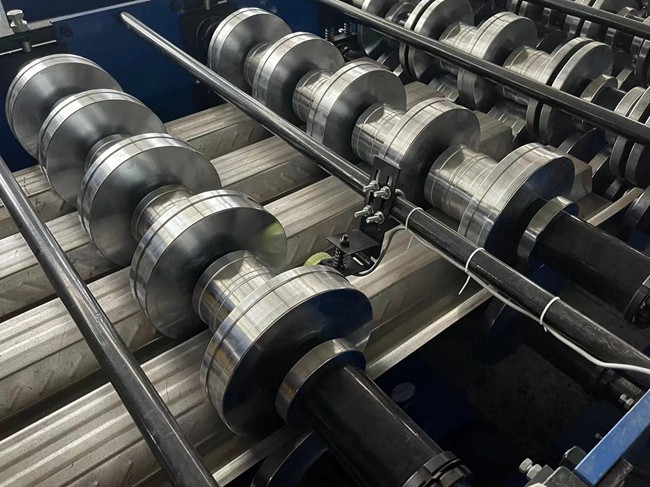

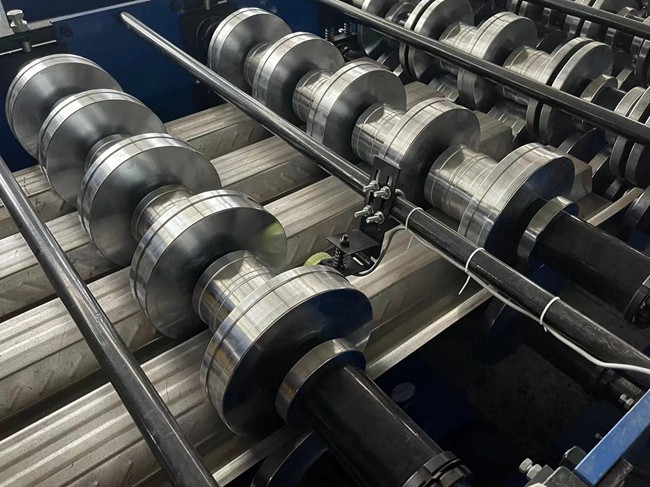

The metal tile forming machine mainly processes metal coils into various shapes and specifications of metal tiles through a series of precise mechanical actions. Firstly, place the metal coil into the material rack of the equipment. The material rack is adjusted according to the diameter and weight of the coil to ensure that the coil can smoothly and smoothly enter the forming part. After entering the forming section, the metal coil is pressed and bent by a series of rollers to form the desired tile shape. In this process, the precise design and adjustment of the rollers are crucial, as they determine the shape and quality of the tiles.

The metal tile copying machine has a wide range of applications in the metal tile processing industry, especially in high-end construction fields such as villas, museums, and tourist buildings that require high-precision and high-quality metal tiles. In addition, with the continuous advancement of technology and the expansion of application fields, metal tile copying machines are expected to play an important role in more fields.

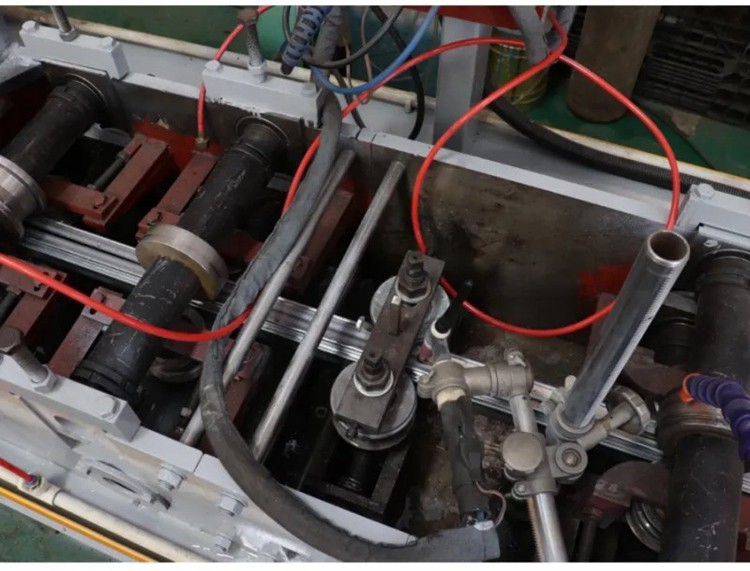

Cold tile forming machine, also known as cold bending forming machine or cold bending tile pressing machine, is a mechanical equipment used to cold process raw materials such as metal coil, sheet or pipe into tiles or profiles of various shapes and specifications. The cold tile forming machine uses a series of precision components such as rollers, molds, and roller shafts to continuously bend and press raw materials laterally, thereby producing finished products with specific shapes, sizes, and materials. Its working principle usually involves placing the metal coil on the bracket of the equipment, and then driving the sprocket through the motor, which in turn drives the cold bending tile roller for cold pressing processing. Finally, the required tiles or profiles are obtained through the cutting system.

The cold tile forming machine usually consists of a large frame base, mechanical transmission system, hydraulic forming and cutting system, electrical control system, and feeding auxiliary system. These parts work together to ensure that the equipment can efficiently and stably complete processing tasks. Cold tile forming machine is an efficient, precise, and flexible metal processing equipment with broad application prospects in multiple industries.

Cold tile forming machines are widely used in various fields such as construction, transportation, home appliances, ships, and petrochemicals. In the construction industry, it can be used to produce components such as lightweight steel structures, steel buildings, roofs, wall panels, arch structures, safety doors, and window frames; In the manufacturing industry, it can be used to produce components such as wind turbine bucket frames, wire reels, and automotive chassis; In the shipbuilding industry, components such as hull structures and deck structures can be produced; In the petrochemical industry, it can be used to produce various pipelines and fittings.

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.