Welcome!

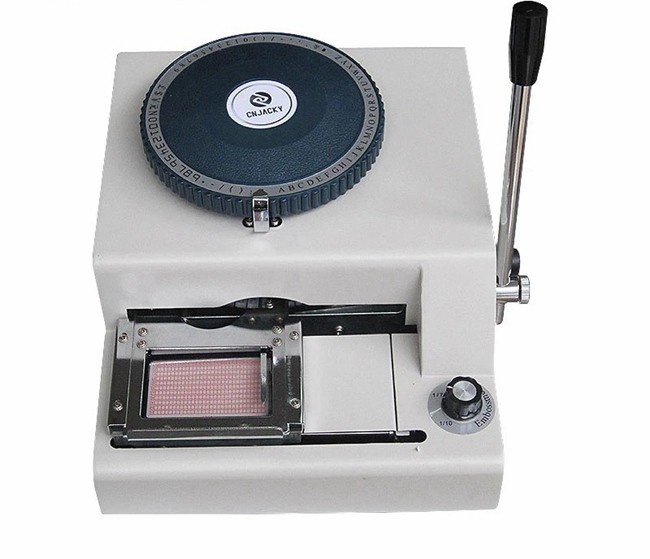

Wholesale Manual PVC ID / IC Card Embosser Machine

Product Description

The dog tag embossing machine usually adopts humanized design, the operation interface is simple and easy to understand, users can quickly get started without professional training. At the same time, the machine is also equipped with safety guards and fault alarm system to ensure the safety and stability of the operation process.

The structure of Dog embossing machine is relatively simple and compact, easy to maintain and repair. Users only need to follow the instruction manual to regularly clean and check all parts of the machine to ensure its long-term stable operation.

Dog embossing machines are usually equipped with a variety of patterns of molds, users can choose the right pattern for embossing according to their needs. In addition, some high-end dog tag embossing machines also support customized mold service, where users can design unique patterns and make molds according to their needs.

With the rise of pet culture and the pursuit of personalization of pets, dog tag embossing machine has become an important tool to realize the personalization of pet dog tags. Through the embossing technology, a variety of exquisite patterns and text can be produced on the dog tags, such as the pet's name, the owner's contact information, etc., which is both beautiful and practical.

Card embossing machines can produce a variety of unique patterns and textures through different combinations of dies and templates to meet personalized needs. Most of the modern card embossing machines adopt intelligent design, which is easy and convenient to operate, even children can easily get started under the guidance of adults. Card embossing machines are usually made of high-quality materials with good durability and safety. At the same time, there are protective devices inside the machine to prevent damage caused by operating errors.

Place the material to be embossed on the die, making sure it is centered and flat. If using a hot melt gun for heat embossing, heat the gun to the proper temperature in advance. Place the mold and material together in the embosser, adjust the pressure to the proper level, and gently press the handle of the embosser to emboss. Keep your hand steady during the embossing process and avoid applying too much force to avoid damaging the machine or the material. When pressing is complete, open the embosser and remove the mold and material. Carefully remove the embossed material from the mold and check if the embossing result is satisfactory. If further processing (e.g. hot foil fusing) is required, follow the appropriate steps.

Recommended Products

Recently Viewed

Wholesale PVC Card Embossing Machine 68 70 72 Character Plastic Card Plate Number Embosser

Wholesale PVC Card Embossing Machine 68 70 72 Character Plastic Card Plate Number Embosser Manufacturer From China PVC Card Embossing Machine 68 70 72 Character Plastic Card Plate Number Embosser

Manufacturer From China PVC Card Embossing Machine 68 70 72 Character Plastic Card Plate Number Embosser Manufacturer From China Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card

Manufacturer From China Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card Customized Characters Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card

Customized Characters Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card Metal Custom Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card

Metal Custom Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card

Contact Us

Zhengzhou Zomagtc Company Ltd.