Welcome!

4 roller automatic plate rolling machine for sale

Product Description

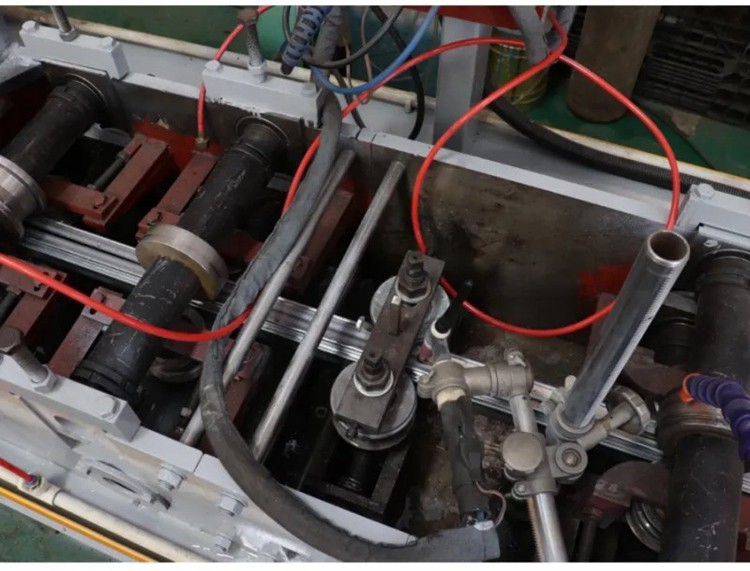

The four-roller automatic plate rolling machine is a device used for bending and forming metal plates. It can efficiently roll round, arc-shaped and conical workpieces within a certain range. It has the characteristics of small residual straight edges and high work efficiency. The four-roller plate rolling machine realizes the bending and curling of the plate by fixing the upper roller and moving the lower roller and the rollers on both sides. It uses the principle of three-point circle setting to roll different radii.

Four-roller plate rolling machine rolling skills

1. The main contents include: analyzing the forming mechanism of four-roller plate rolling, deriving the stress-strain relationship and curvature-bending moment relationship at any cross section when the plate is bent; theoretical analysis based on the classic unloading rebound model, and obtaining the calculation formula of the plate rebound radius; analyzing the geometric position of each axis roller in the rolling process and the stress condition of the plate, and establishing the geometric models of the four-roller plate rolling pre-bending stage and the multi-pass rolling stage. Based on ABAQUS finite element software, finite element models of the shaft roller and the plate in the rolling stage and the unloading and rebound stage were established; the influencing factors of the angularity phenomenon were analyzed, and a theoretical model of the pre-bending section distance of the plate was established; through the stress-strain field analysis of the deformation zone, the strain field analysis of the lower surface of the plate, the circumferential curvature analysis of the rolled plate and the quality analysis of the rolled plate joint, the reasons for the angularity of the plate were obtained, and the influence of single-pass forming and multi-pass forming on the angularity phenomenon of the plate was analyzed.

2. The roller movement forms of the four-roller CNC plate rolling machine and the three-roller CNC plate rolling machine are different, but the working principles are the same. They all use the principle of three-point circle determination to roll different radii. However, the straight edge and roundness of the pre-bent four-roller CNC plate rolling machine are better than those of the three-roller.

3. The upper roller is fixed in position, and the lower roller moves upward in a straight line to clamp the steel plate. The rollers on both sides move in a straight line or arc to move closer to the upper roller to adjust the curvature radius of the roll. The roller movement forms of the four-roller and three-roller plate rolling machines are different, but the working principles are the same. They all use the principle of three-point circle determination to roll different radii.

Automatic parameter setting of four-roll plate rolling machine

1. The W12 CNC four-roll plate rolling machine is equipped with a programmable CNC system, which can store automatic rolling data of hundreds of different workpieces, and realize one-key call and one-key start. No manual operation is required, and the workpiece rolling is completed automatically. This model not only meets the automatic rolling processing of circular shapes, but also meets the automatic rolling of various arc-shaped, square, triangular, oblate, elliptical and other workpieces. The operating system is equipped with an EPS electronic automatic leveling system, which can automatically adjust the parallelism of the moving axis to ensure product quality. The equipment completes material alignment, pre-bending and rolling in one rolling process. The remaining straight edge of the pre-bending is ≤5 times the plate thickness, and the rolling accuracy is high, which can meet the requirements of automatic welding. This model adopts the patented technology of inverted side roller cylinder, which can effectively reduce the height of the fuselage while improving the sliding stability and reducing equipment failures, meet the ground installation requirements, and reduce the user's equipment foundation pit and other infrastructure construction costs.

2. The four-roller plate rolling machine is a fully servo automatic type, which is used to roll steel plates into cylindrical, square, oval, and D-shaped shapes at room temperature; it adopts a computer program control system. Main technical parameters: W12CNC-8×600

3. Before setting the automatic rolling parameters, you need to understand the following parameters: Thickness and hardness of the plate rolling material: The thickness and hardness of the plate rolling material will affect the rolling ability of the four-roller plate rolling machine. Thinner materials are relatively easy to roll, while thicker materials require greater rolling force.

4. Among them, the four-roller plate rolling machine can process plates with a thickness of 250mm and a width of 4000mm. The arc four-roller plate rolling machine has adopted CNC control. The advantages are that it uses hydraulic drive, high transmission efficiency, and small size; it uses lubrication-free bearings; the diameter of the roll is small, only 1 times the diameter of the upper roller

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.