Welcome!

High-precision hydraulic plate rolling machine

Product Description

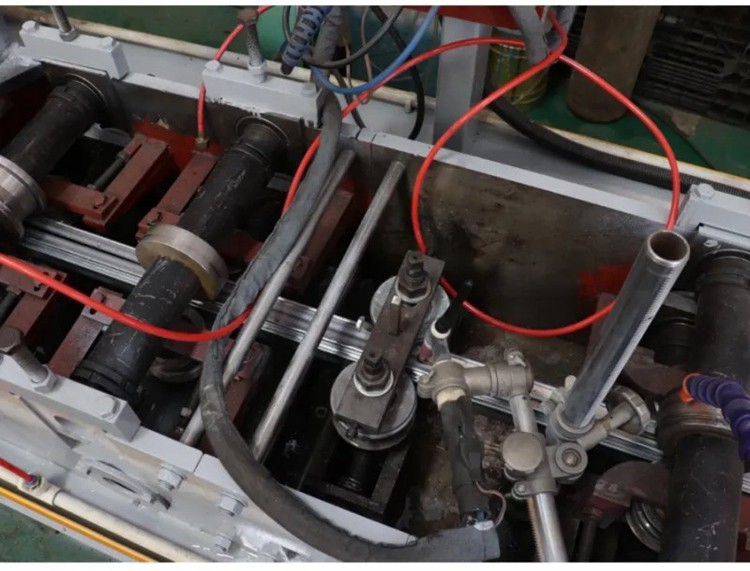

Hydraulic plate rolling machine is a shaping machine tool for continuous point bending of sheet metal. The hydraulic plate rolling machine is a shaping machine tool for continuous point bending of sheet metal. The upper roller is at the central symmetrical position of the two lower rollers. The hydraulic oil in the hydraulic cylinder acts on the piston to make vertical lifting and lowering movements. The final gear of the main reducer drives the two lower rollers to mesh and rotate to provide torque for rolling the sheet metal. The flat plastic metal plate of the plate rolling machine passes between the three working rollers (two lower rollers and one upper roller) of the plate rolling machine. With the help of the downward pressure of the upper roller and the rotation of the lower roller, the metal plate undergoes multiple continuous bendings, produces permanent plastic deformation, and is rolled into the required cylindrical, conical or part of them.

Product advantages

1. The high-precision hydraulic plate rolling machine adopts a hydraulic transmission design, which makes the operation smooth and reliable, ensuring the stability and accuracy of the plate rolling process.

2. Equipped with a special plate rolling machine CNC system E20 for the rear gauge, the plate rolling times have a digital display device, which improves the accuracy and convenience of the operation.

3. The fully automatic plate rolling machine plate press adopts an independent hydraulic press, and each press has a plastic pad at the end to protect the workpiece surface from damage and ensure the uniform distribution of pressure.

4. The all-steel welded structure is adopted, and the vibration eliminates stress to ensure the high strength and good rigidity of the machine, and improve the durability and stability of the machine.

5. The rolling support device reduces friction while ensuring that the workpiece surface is not scratched, further improving the quality of the plate rolling.

6. The high-precision hydraulic plate rolling machine has the function of stepless adjustment of the stroke, and the gap between the upper and lower blade edges is adjusted by the handle to ensure the uniformity of the blade gap and the accuracy of the plate rolling.

7. It adopts hydraulic transmission and swing-type tool holder. The overall welding of the frame is sturdy and durable. The accumulator cylinder has a smooth and rapid return stroke, ensuring the high efficiency and stability of the machine.

Maintenance and care

1. According to the provisions in the machine lubrication diagram, refuel each oil cup lubrication and manual lubrication point as required.

2. Roll the plate according to the parameters specified by the hydraulic plate rolling machine. The thickness of the plate rolling is 20mm, the maximum length is 2500mm, and the yield limit of the plate rolling material is less than 250Mpa.

3. After turning on the power, perform the positive and negative directions of the lower roller and the lifting and lowering of the upper roller, and check whether there is abnormal jamming in each movement.

4. Strictly operate according to the plate rolling processing procedures and operating methods of the hydraulic plate rolling machine. When the upper roller is lifted to the limit position, pay great attention to the safe operation of the equipment.

5. Only when the main drive is stopped can the upper roller be lifted and lowered, the tilting and resetting of the flip bearing and the lifting of the upper roller be carried out.

6. During the operation, if irregular noise, impact and other abnormal phenomena are found, the machine should be stopped immediately for inspection.

7. During the operation, all personnel should coordinate with each other and obey the command of the person in charge of the plate rolling. It is forbidden to start the machine without a command.

8. When rolling plates with a hydraulic plate rolling machine, be careful not to let your hands get pressed by the steel plate and rolled in together with the steel plate.

9. When lifting steel plates or rolls with a crane, be careful not to collide with the machine.

After the hydraulic plate rolling machine is finished, make sure that the site is cleaned up after the work is completed, and do a good job of equipment maintenance and turn off the power in time.

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.