Welcome!

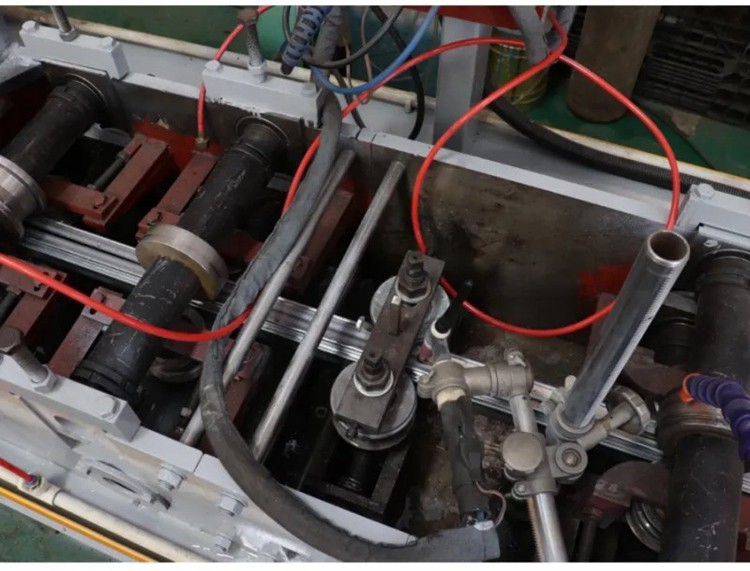

4 roll plate bending machine manufacturer

Product Description

Instructions for use

The four-roller plate rolling machine is mainly used for bending and forming metal sheets. It can roll round, arc-shaped and tapered workpieces within a certain range, and has the function of pre-bending the end of the plate. The basic operating steps are as follows:

Preparation: Make sure the equipment is in good condition and check whether all safety devices are normal.

Loading: Place the metal sheet on the lower roller to ensure that the sheet is flat and not twisted.

Adjust the roller spacing: Adjust the position of the upper roller and side rollers according to the shape and size of the workpiece to be rolled.

Start the equipment: Start the hydraulic system to raise the lower roller and press the end of the plate between the upper and lower rollers.

Rolling process: By controlling the hydraulic system, the plate is rolled step by step until the required shape and size are reached.

Unloading: After rolling, remove the plate from the equipment for subsequent processing.

Advantages and Disadvantages

advantage:

High precision: The four-roller plate rolling machine has highly precise processing capabilities and can achieve precise control of the thickness and shape of metal sheets to ensure product quality and dimensional consistency.

Efficient production: Due to the efficient rolling speed of the four-roller plate rolling machine, production efficiency can be significantly improved.

Versatility: Works with a variety of workpiece shapes and sizes, including round, curved and tapered workpieces.

shortcoming:

Complex operation: Although the four-roller plate bending machine is easy to use, first-time operators may need some time to become familiar with the equipment.

Maintenance costs: Due to the complexity and precision of the equipment, maintenance costs are relatively high.

Operating procedures

Safety inspection: Before operation, equipment safety inspection must be carried out to ensure that all safety devices are working properly.

Multi-person collaboration: When multiple people work together, there must be a dedicated person to direct to ensure that the operation is carried out in an orderly manner.

No overload: Overload work is strictly prohibited to avoid equipment damage.

Interruption handling: After the work is interrupted, the clutch should be put into neutral to prevent accidental start-up.

Precautions

Hand and foot safety: During operation, it is strictly forbidden to put hands and feet on the rollers, transmission parts and workpieces to prevent accidental injuries.

Equipment maintenance: Regular equipment maintenance and maintenance to ensure long-term stable operation of the equipment.

Operation training: Operators must undergo professional training and be familiar with the equipment's operating procedures and safety precautions.

Recommended Products

Recently Viewed

Fully automatic steel frame Profile Cold Roll Forming Machine

Fully automatic steel frame Profile Cold Roll Forming Machine Sell sheet metal Roll Forming machines at factory prices

Sell sheet metal Roll Forming machines at factory prices Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication

Plate Rolling Machine: Advanced Solutions for Industrial Metal Fabrication Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation

Plate Rolling Machine: Revolutionizing Metal Fabrication with Smart Innovation Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Precision Plate Rolling Machine: High-Efficiency Metal Forming with Unmatched Durability

Contact Us

Chifeng Bashiker Import&Export Trade Co., Ltd.