Welcome!

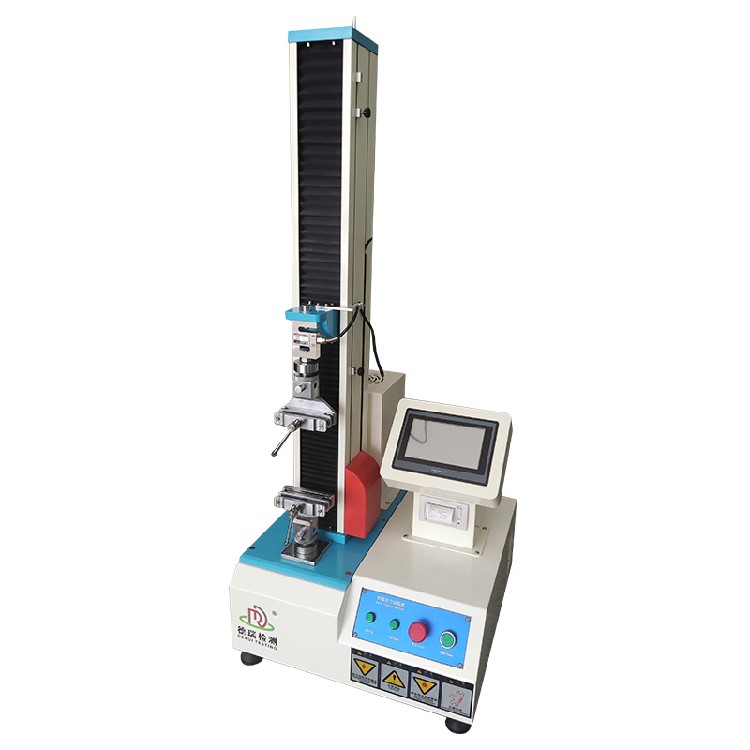

Desktop single-column tensile testing machine

Basic Info

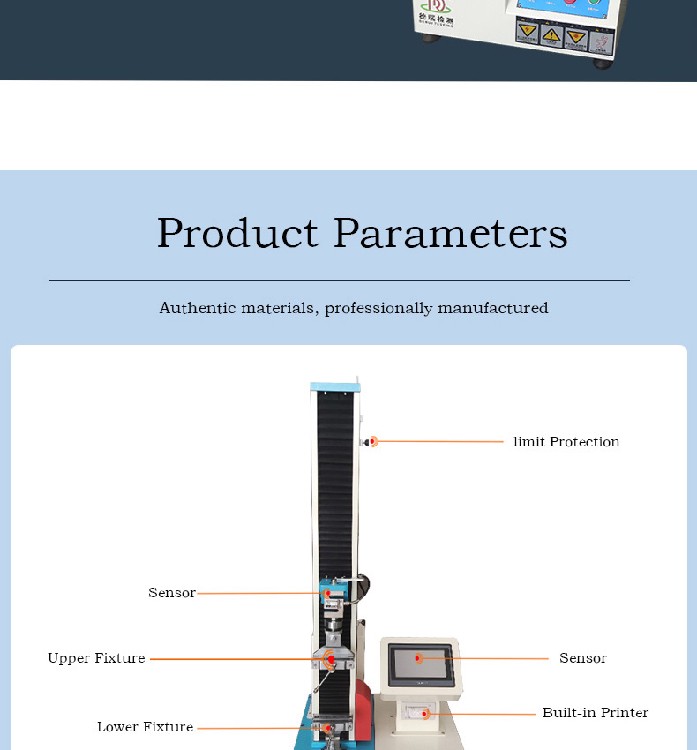

| Desktop Single-Column Tensile Testing Machine | DR-H201 | Load Capacity | 0.5 kN, 1 kN, 5 kN, 10 kN, 20 kN (customizable) | Load Cell | ±0.5% Accuracy, 1 N to 20 kN (depending on capacity) |

|---|---|---|---|---|---|

| Max Test Stroke | 600 mm, 1000 mm (customizable) | Model Type | Desktop Single-Column Tensile Testing Machine | Power Supply | 220V, 50/60Hz (customizable for different regions) |

| Testing Method | Tensile, Compression, Bending, Shear (depending on fixtures) | ||||

Product Description

Desktop Single-Column Tensile Testing Machine

A Desktop Single-Column Tensile Testing Machine is a compact, laboratory-scale testing system designed to measure the tensile strength, elongation, and mechanical properties of materials and small components. This type of testing machine is ideal for use in environments where space is limited, such as research labs, educational settings, or small-scale production areas. The single-column design, with its straightforward vertical testing structure, makes it easy to use while still offering the precision needed for accurate material testing.

These machines are often used to test a wide variety of materials, including metals, plastics, rubber, textiles, and composites, as well as small finished products like connectors, wires, and fasteners.

Product Features

- Compact Desktop Design:Space-Saving: The machine is designed for desktop use, requiring minimal space in the laboratory or testing area, making it ideal for small workspaces or educational institutions.Lightweight Construction: The compact single-column structure ensures that the machine is lightweight and easy to transport or relocate when needed.

- High-Precision Load Cell:Accurate Force Measurement: Equipped with a high-precision load cell, the tensile testing machine offers accurate force measurement across a broad range of testing materials. The load cell ensures that the force applied during the test is measured with high accuracy and is displayed in real-time.Wide Load Capacity Range: These machines often come in various load capacities, typically ranging from 1 kN to 50 kN, depending on the model and application requirements.

- Servo Motor Drive System:Smooth Testing Process: The machine uses a servo motor drive system to move the crosshead smoothly and accurately. This ensures consistent testing conditions, particularly important for materials with low tensile strength or small test samples.Precise Speed Control: The servo motor allows for precise speed control of the testing process, enabling slow or fast test cycles as required by the material or test specification.

- Digital Control System:Touchscreen Interface: The machine is equipped with an easy-to-use touchscreen control panel that allows the operator to set parameters like testing speed, load limits, and displacement limits. Users can easily start, stop, or pause the test with simple controls.Test Programming: The control system often supports pre-set test programs for various materials, providing the ability to automate and standardize testing for repeatability.Data Logging and Analysis: The system can log test data such as force vs. displacement, stress vs. strain, and load vs. elongation. The data can be analyzed immediately or stored for future reference, either via a built-in software solution or exported to external programs like Excel.

- Adjustable Crosshead:Variable Distance Adjustment: The crosshead is adjustable, allowing for testing of different sample sizes and accommodating a wide range of specimen thicknesses and lengths.Easy Sample Mounting: The crosshead's adjustable height makes it easy to mount samples with varying lengths or geometries.

- Safety Features:Emergency Stop Button: An emergency stop button ensures safe operation, allowing the machine to halt immediately in case of a malfunction or unexpected behavior.Overload Protection: The system has built-in overload protection, preventing damage to the machine in case of excessive force beyond the set limits.Safety Shields: Some models include protective shields around the sample area to protect users from flying debris or broken samples during testing.

- Versatile Grips and Fixtures:Various Grip Options: The machine is often supplied with a variety of grip types (e.g., manual or pneumatic grips, clamp grips, tensile jaws) that are interchangeable, allowing it to hold different materials securely during testing.Customizable Fixtures: Custom fixtures and adapters can be added for non-standard samples, including thin wires, small metal sheets, or films.

Product Characteristics

- Ideal for Small Samples:The desktop single-column tensile testing machine is perfect for testing small samples, such as small components, films, wires, foils, textiles, and other thin materials, that cannot be tested with larger machines. This makes it highly suitable for R&D and educational use.

- High Accuracy and Precision:With high-precision sensors and an advanced control system, these machines deliver accurate and reliable tensile testing results. They provide valuable data for material engineers and product developers working with new or unique materials.

- Compact and Portable:This machine's compact design makes it portable and easy to store, offering a space-efficient alternative to larger tensile testing machines.

- Low-Cost Option for Research and Education:Given its relatively affordable price point, the desktop single-column tensile testing machine is an excellent choice for small research labs, educational institutions, and testing labs that don’t require the capacity or complexity of industrial machines but still need precise testing capabilities.

Usage Guidelines

- Preparing Samples:Ensure that test samples are properly prepared and cleaned before testing. For consistent results, ensure that each sample is cut or prepared to meet the required dimensions for the test (e.g., gauge length, thickness).Mount samples securely in the grips, ensuring that they are aligned and properly centered to prevent slippage during testing.

- Programming and Calibration:Before starting the test, program the test parameters (e.g., speed, load limits, displacement) via the control panel. It is important to calibrate the load cell and displacement sensors periodically to ensure accurate readings.If necessary, set up the test profile to match the material standards (e.g., ASTM, ISO) that apply to the sample.

- Monitoring the Test:Start the test and monitor it through the digital control system, ensuring the testing machine is running smoothly and that no abnormalities occur during the process.The test is typically performed until the material breaks or reaches a specific strain value, depending on the material type and test requirements.

- Data Collection and Analysis:Once the test is complete, use the control system to review the data, including the tensile strength, elongation, stress-strain curve, and other relevant mechanical properties.The data can be saved for future analysis or compared against material standards to assess the material’s performance under tensile stress.

- Post-Test Sample Inspection:After the test is completed, inspect the sample for visible signs of failure (e.g., fractures, cracks, or stretching). This can provide valuable insights into the material's performance characteristics and its suitability for specific applications.

- Regular Maintenance:Periodically check the load cell, servo motor, grips, and crosshead for any signs of wear and tear. Keep the machine clean and well-maintained to ensure accurate results and extend its service life.

Installation Environment

- Space Requirements:As a desktop unit, this machine is designed to fit into small spaces, but ensure there is enough room for easy access to the control panel, grips, and sample mounting areas. A typical workstation area of about 2 square meters is usually sufficient.

- Power Supply:The machine operates on standard 110V or 220V electrical power (depending on the model). Check the manufacturer's specifications for power requirements to ensure compatibility with your facility’s electrical system.

- Environmental Conditions:The machine should be operated in a well-ventilated area with a stable ambient temperature (ideally between 18°C and 25°C). Excessive dust or extreme temperatures may affect the performance of the load cell or other components.

- Safety Precautions:Install the machine in a location that minimizes the risk of accidental impacts or obstructions to its operation. Make sure protective safety shields (if provided) are in place to prevent injury during testing.Ensure the work area is free from hazards and that operators are trained in using the testing machine safely.

Conclusion

A Desktop Single-Column Tensile Testing Machine is a highly versatile, compact, and cost-effective solution for testing small samples or components under tensile stress. With its precise load measurement, programmable test profiles, and easy-to-use digital controls, this machine is ideal for research, development, quality control, and educational purposes. It is especially suited for small-scale laboratories or environments where space is at a premium but where accurate and reliable mechanical testing is still required. Whether you're testing plastics, metals, textiles, or composites, this machine provides the capability to gather meaningful data on material performance under stress, helping to drive product development and material analysis.

4o

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.