Welcome!

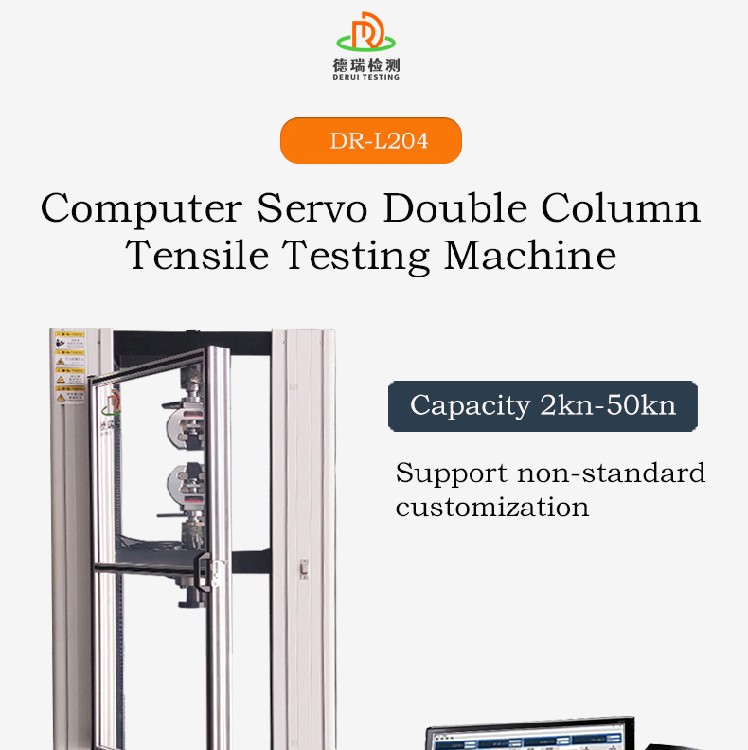

High-load double-column tensile testing machine

Basic Info

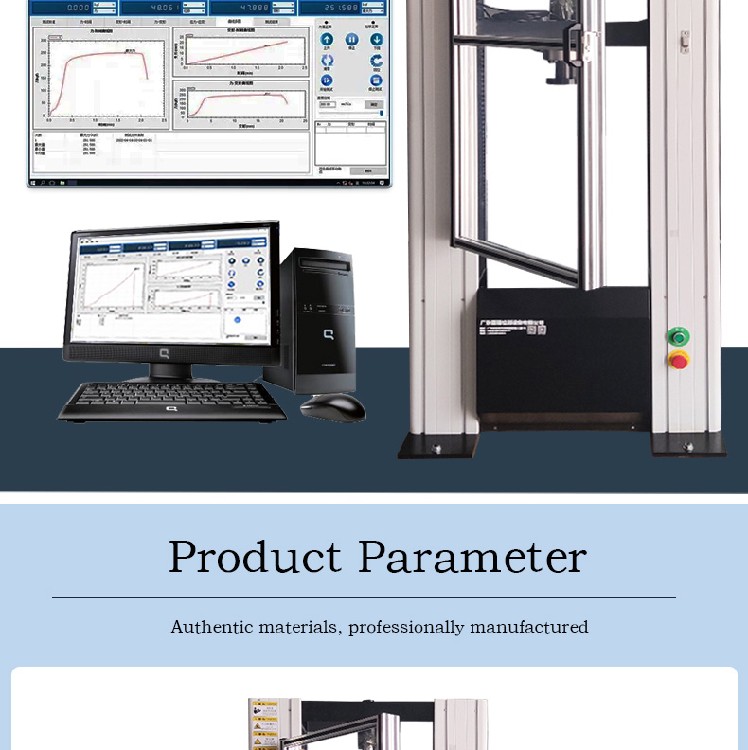

| Crosshead Speed Range | 0.001 mm/min to 1000 mm/min (adjustable) | Displacement Measurement | LVDT (Linear Variable Displacement Transducer) | Electrical Supply | 220V, 50/60Hz (customizable for different regions) |

|---|---|---|---|---|---|

| Frame Type | Double column vertical frame | Load Accuracy | ±0.5% of full scale or better | Load Measurement | Load cell with high precision (digital or analog) |

| Max Testing Force | 100 kN, 200 kN, 300 kN, 500 kN (customizable) | Model | DR-L202 | Model Type | Double-Column Tensile Testing Machine |

Product Description

High-capacity Dual-column Tensile Testing Machine

A High-capacity Dual-column Tensile Testing Machine is a specialized device designed for testing high-strength materials or large components. It can apply substantial forces to evaluate the mechanical properties of samples under tensile loads, such as strength, elastic modulus, elongation, and fracture toughness. This type of testing machine is widely used in industries like metals, composites, automotive parts, ensuring product quality and safety.

Structural Features

- Dual-column Frame: Utilizes two vertical columns to support the entire system, offering higher rigidity and stability, suitable for handling larger loads.

- Large Travel Testing Space: Provides an extensive vertical travel range, accommodating samples of varying lengths and shapes.

- Powerful Drive System: Equipped with high-performance motors and transmission mechanisms, ensuring stable application of tensile forces ranging from several Newtons up to hundreds of kilonewtons or more.

- Precision Sensors: Incorporates high-precision load cells and displacement encoders for accurate measurement of applied force and sample deformation.

- Safety Protection Devices: Includes emergency stop buttons, overload protection, limit switches, etc., to ensure operator safety.

Functions and Applications

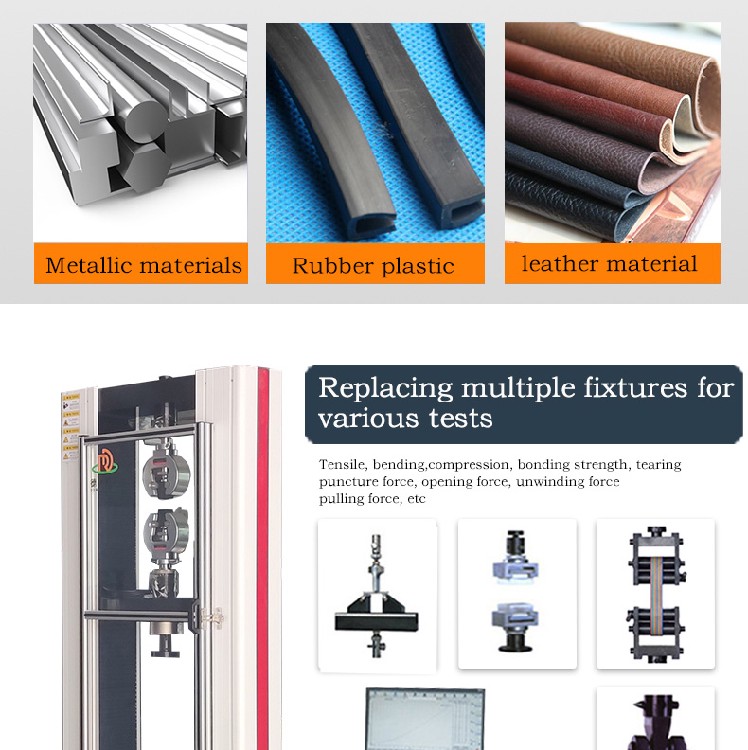

- Multi-mode Testing Capability: Beyond basic tensile testing, it can also perform compression, bending, shear, and other types of mechanical tests by simply changing the fixtures.

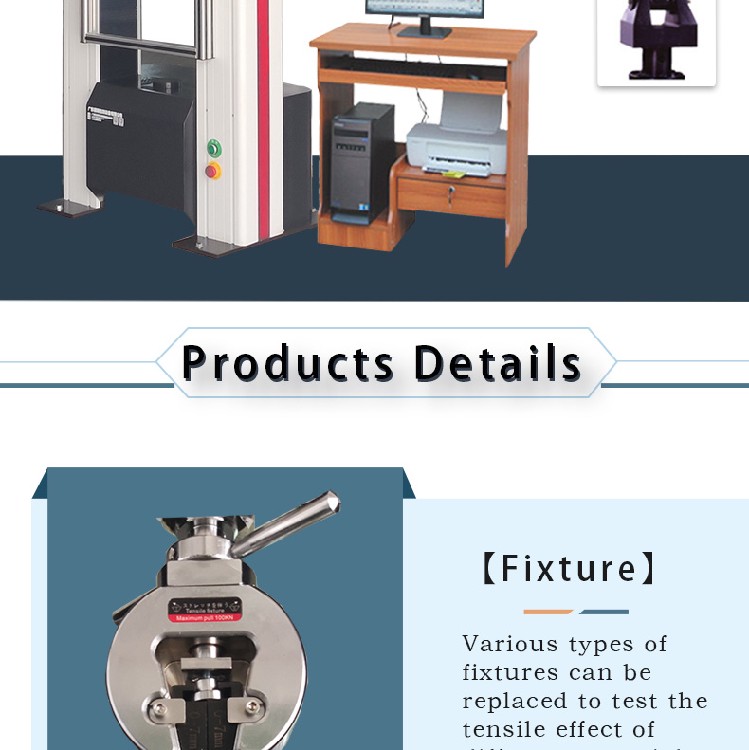

- High Degree of Automation: Modern machines typically come with automatic control systems that can preset test programs and execute them automatically, minimizing human error.

- Data Processing and Analysis: Integrated data acquisition systems record various parameters during testing in real-time and analyze data through software to generate reports.

- Compliance with International Standards: Manufactured according to international standards such as ISO, ASTM, DIN, ensuring valid and comparable test results.

Operational Convenience

- User-friendly Interface: Intuitive control panels or touchscreens simplify setup and operation.

- Quick Fixture Replacement: Designed with easy fixture change mechanisms to adapt quickly to different types of samples.

- Simple Maintenance: Modular design facilitates daily maintenance and repairs, reducing long-term operating costs.

Application Fields

The high-capacity dual-column tensile testing machine is applicable in the following sectors:

- Metallic Materials: Such as steel, aluminum alloys, titanium alloys, and their products.

- Composite Materials: Advanced composites like carbon fiber-reinforced plastics (CFRP) and glass fiber-reinforced plastics (GFRP).

- Automotive Industry: Performance testing of critical structural components like chassis, suspension systems, seat belts.

- Aerospace: Strict quality control of aircraft structural components, engine parts.

- Construction Industry: Reliability verification of construction materials like reinforced concrete, bridge cables.

Selection Considerations

When selecting a high-capacity dual-column tensile testing machine, consider the following aspects:

- Maximum Load Capacity: Choose a machine with appropriate tonnage based on the maximum expected stress of the materials to be tested.

- Accuracy Requirements: Define the required measurement accuracy, especially for advanced research or stringent quality inspections.

- Additional Functional Needs: Determine if environmental chambers for temperature simulation or video extensometers for non-contact strain measurement are needed.

- Space and Budget Constraints: Plan laboratory space layout reasonably and make choices within budget.

- After-sales Service Support: Prioritize brands that offer good technical support and service networks.

In summary, the high-capacity dual-column tensile testing machine stands out with its robust testing capabilities and precise data output, becoming an indispensable part of many industrial fields, providing solid technical support for ensuring product performance.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.