Welcome!

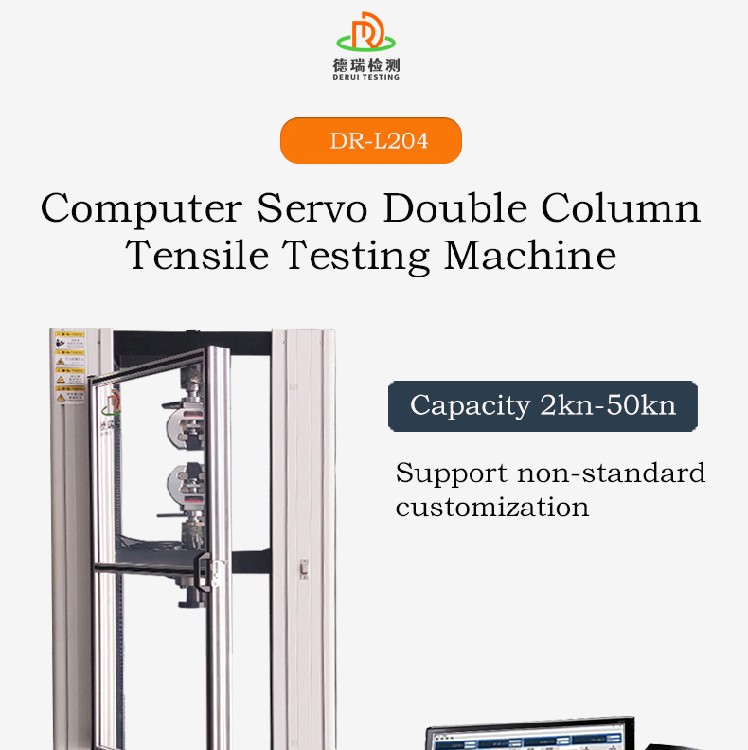

Long-term stable double-column tensile testing machine

Basic Info

| Clamping Mechanism | Hydraulic or pneumatic clamping (manual options also available) | Displacement Resolution | 0.001 mm | Electrical Supply | 220V, 50/60Hz (customizable for different regions) |

|---|---|---|---|---|---|

| Frame Material | High-quality steel or aluminum alloy | Frame Verticality | ≤ 0.2 mm (ensures accurate testing) | Machine Weight | 600 kg - 2000 kg (depending on model) |

| Model | DR-L202-2 | Power Safety | CE, UL, or CSA certified components | Test Mode Options | Single test, multiple step test, cyclic testing, stress-relaxation |

| Test Specimen Holder Type | Pneumatic or manual clamping (customizable) | ||||

Product Description

Long term stable double column tensile testing machine

A long-term stable double column tensile testing machine is a device designed specifically for testing high-strength materials or large components that require continuous and reliable performance. It can maintain high precision and stability over a long period of time, ensuring accurate and error free tensile loads applied to the sample, thereby accurately evaluating the mechanical properties of the material, such as strength, elastic modulus, elongation, and fracture toughness. This type of testing machine is widely used in industries such as metals, composite materials, and automotive parts, and is crucial for ensuring product quality and safety.

Structural characteristics

Double column frame: using two vertical columns to support the entire system, providing higher rigidity and stability, suitable for carrying large loads, and maintaining structural stability during long-term use.

Large travel testing space: With a large range of up and down movement, it is suitable for specimens of different lengths and shapes, ensuring sufficient operating space even during long-term testing.

Powerful Drive System: Equipped with high-performance motors and transmission mechanisms, ensuring stable application of tensile forces ranging from a few newtons to hundreds of kilonewtons or even higher, while maintaining long-term reliability.

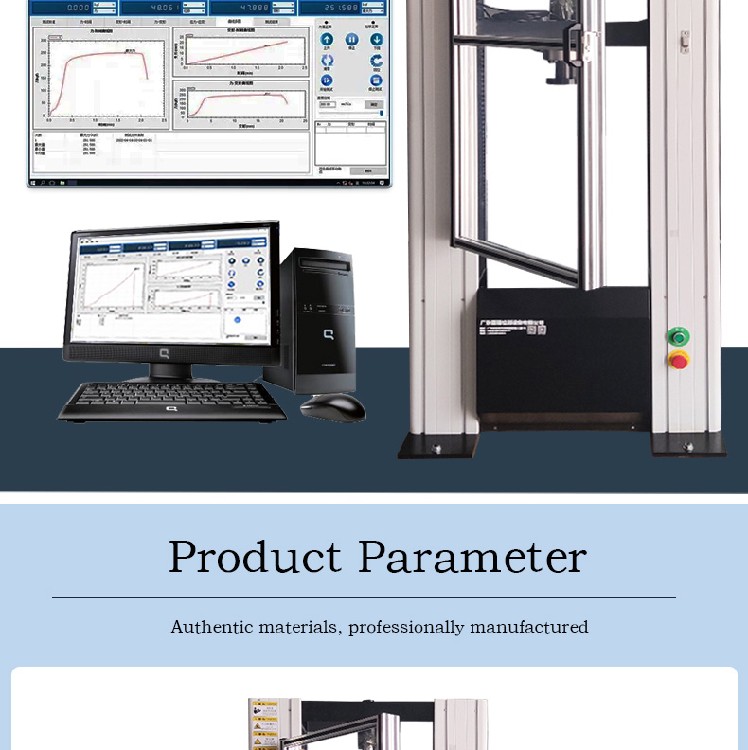

Precision Sensor: Equipped with high-precision load sensors and displacement encoders, it can accurately measure the applied force and deformation of the specimen even after prolonged use.

Safety protection devices: including emergency stop buttons, overload protection, limit switches, etc., to ensure the safety of operators, especially in unattended operating environments for long periods of time.

Functions and Applications

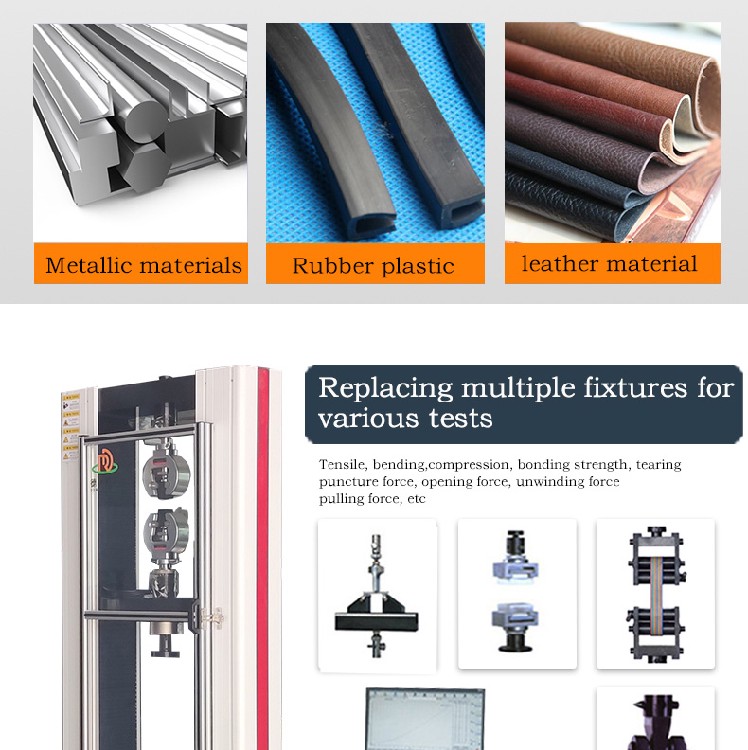

Multi mode testing capability: In addition to basic tensile testing, it can also perform various types of mechanical tests such as compression, bending, and shearing, simply by replacing the corresponding fixtures.

High degree of automation: Modern models are usually equipped with automatic control systems that can preset test programs and execute them automatically, reducing human error and making them particularly suitable for long-term continuous testing.

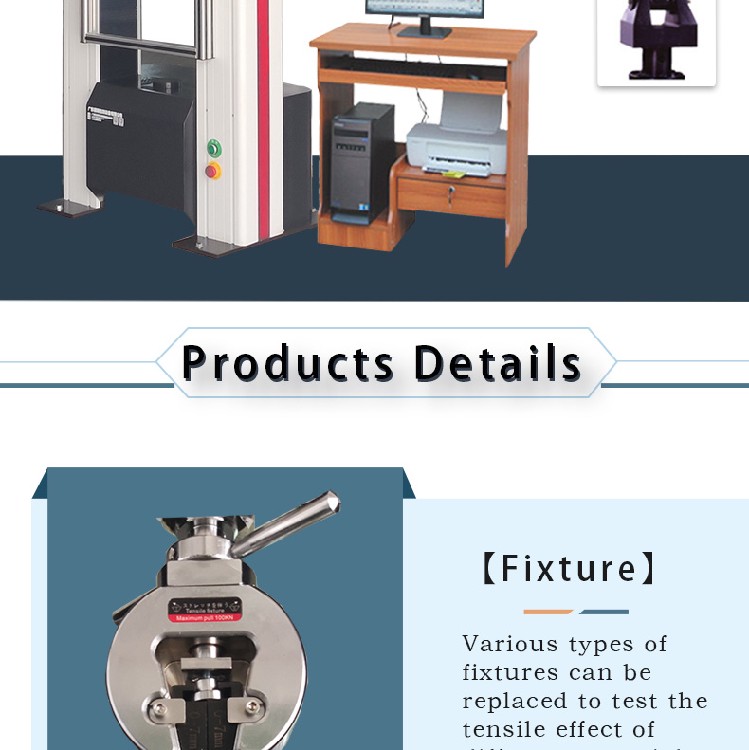

Data processing and analysis: The integrated data acquisition system can record various parameters during the testing process in real time, and perform data analysis and report generation through software, supporting long-term data tracking and analysis.

Compliant with international standards: According to ISO, ASTM, DIN and other international standards ensure the validity and comparability of test results, providing consistent results in both short-term and long-term testing.

Operational convenience

User friendly interface: intuitive operation panel or touch screen control, simplified settings and operation process, convenient for long-term use.

Quick fixture replacement: Designed with a convenient fixture replacement mechanism, it is easy to adjust to accommodate different types of specimens, even during long-term testing.

Easy maintenance: Modular design facilitates daily maintenance and repair, reduces long-term operating costs, and ensures that the equipment is always in optimal working condition.

Scope of application

The long-term stable double column tensile testing machine is suitable for the following fields:

Metal materials: high-strength metals and their products such as steel, aluminum alloys, titanium alloys, etc., especially suitable for materials that require long-term performance evaluation.

Composite materials: Advanced composite materials such as carbon fiber reinforced plastic (CFRP), glass fiber reinforced plastic (GFRP), etc., which typically require long-term performance testing.

Automotive industry: Performance testing of key structural components such as frames, suspension systems, and seat belts, especially those components that require verification of long-term reliability.

Aerospace: Strict quality control of aircraft structural components, engine parts, etc. to ensure long-term stable operation even under extreme conditions.

The reliability verification of infrastructure materials such as reinforced concrete and bridge cables in the construction industry is particularly important when evaluating long-term durability.

Selection precautions

When choosing a long-term stable double column tensile testing machine, the following aspects should be considered:

Maximum load capacity: Select a suitable tonnage machine based on the maximum expected stress of the tested material to ensure that it can meet the long-term testing requirements.

Accuracy requirements: Clearly define the required measurement accuracy, especially for high-end research or strict quality inspection scenarios, where long-term stability is particularly important.

Additional functional requirements: such as whether an environmental chamber is needed to simulate temperature changes, or a video extensometer for non-contact strain measurement, which may become a necessary condition in long-term testing.

Space and budget constraints: Reasonably plan the layout of laboratory space and make the best choice based on budget, considering the total cost of ownership for long-term use.

After sales service support: Priority should be given to brand suppliers who provide excellent technical support and service networks to ensure timely assistance in case of problems encountered during long-term use.

In short, the long-term stable double column tensile testing machine has become an indispensable part of many industrial fields with its powerful testing capabilities and accurate data output over a long period of time, providing solid technical support to ensure product performance.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.