Welcome!

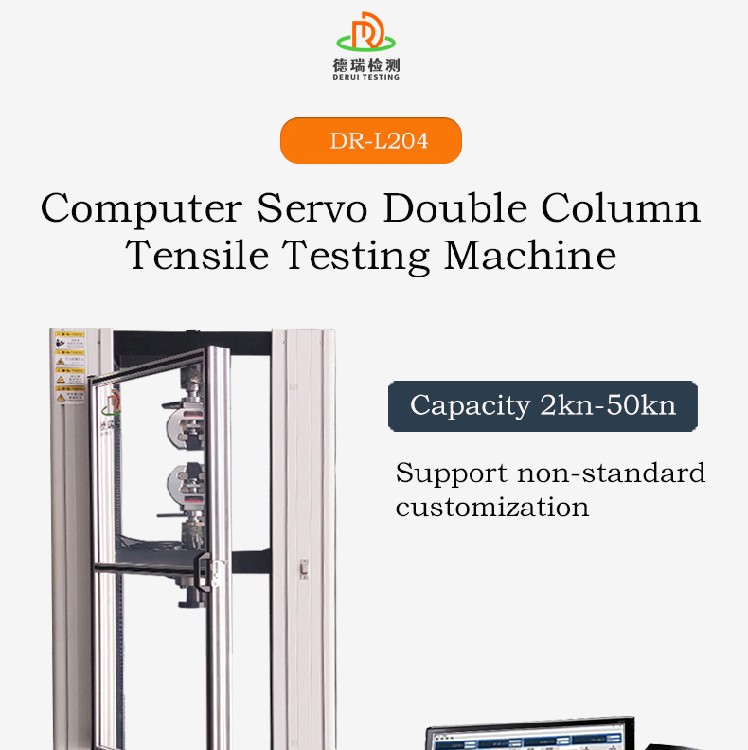

Quality Acceptance Computer-controlled Dual-column Tensile Testing Machine

Basic Info

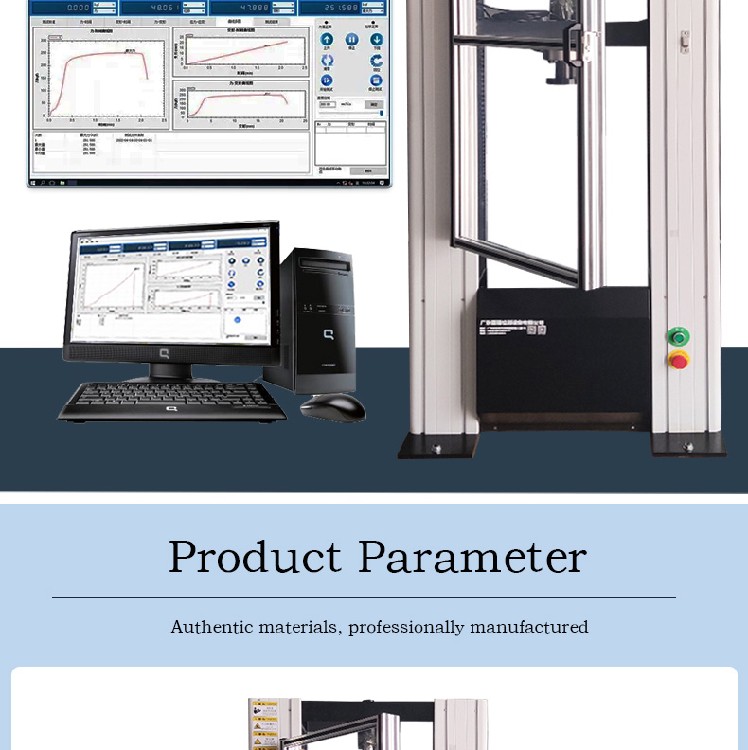

| Control Panel | User-friendly touch panel for test programming | Data Storage | Built-in storage for test results and test sequences | Electrical Supply | 220V, 50/60Hz (customizable for different regions) |

|---|---|---|---|---|---|

| Force-Displacement Curve | Real-time graphical plotting of force vs. displacement | Maximum Speed | 1000 mm/min (adjustable speed) | Model | DR-H202-3 |

| PC Interface | USB, Ethernet, or wireless communication (optional) | Safety Features | Overload protection, emergency stop button, safety shields | Tensile Modulus Measurement | Automatic calculation of Young's modulus (elastic modulus) |

| Test Duration | Adjustable from seconds to hours depending on test type | Test Modes | Constant load, constant elongation, cyclic load, constant stress | ||

Product Description

How to Choose the Right Computer-controlled Dual-column Tensile Testing Machine for Quality Acceptance

Selecting the appropriate Computer-controlled Dual-column Tensile Testing Machine for quality acceptance involves considering multiple factors to ensure that the chosen equipment meets specific testing requirements and provides reliable long-term performance. Below are key elements to focus on during the selection process:

1. Clarify Testing Requirements

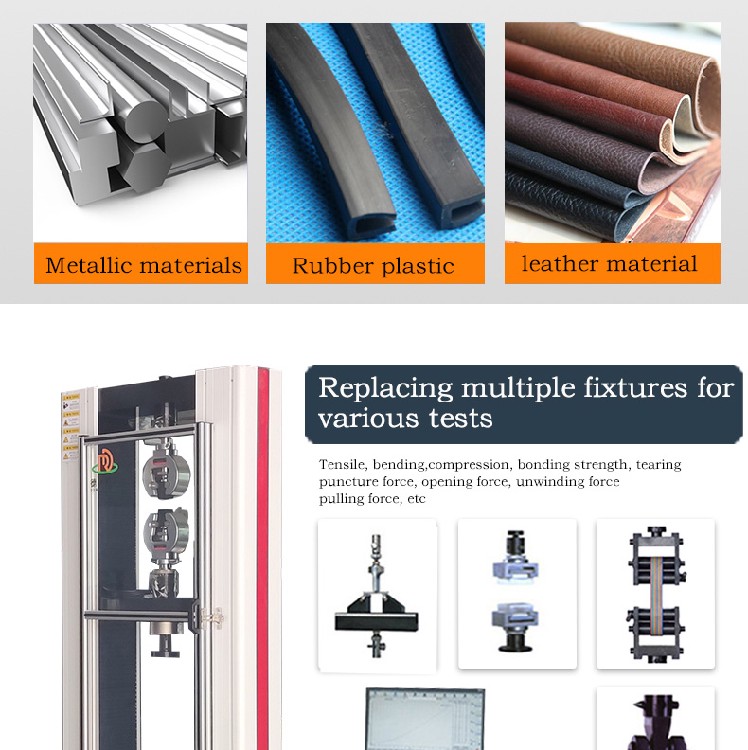

- Material Type: Determine the types of materials you will be testing (e.g., metals, plastics, composites), as different materials may require different fixtures and testing conditions.

- Maximum Load Capacity: Assess the maximum expected stress of your samples and choose a machine with an appropriate load range. It's generally advisable to select a machine capable of handling 3 to 10 times the anticipated maximum load.

- Testing Speed and Travel Distance: Select a suitable speed range (e.g., 5~300mm/min) and travel length (e.g., 600mm~1000mm) based on the size and characteristics of various samples.

2. Precision and Measurement Capabilities

- Force Measurement Accuracy: Ensure the machine’s force measurement accuracy meets standards, such as within ±0.5%. For applications requiring high precision, opt for even more accurate sensors.

- Displacement Accuracy: The accuracy of displacement measurement is equally important, especially when analyzing elongation or fracture points.

- Data Acquisition Frequency: A high sampling rate helps capture rapidly changing data, enhancing the reliability of test results.

3. Automation and Software Features

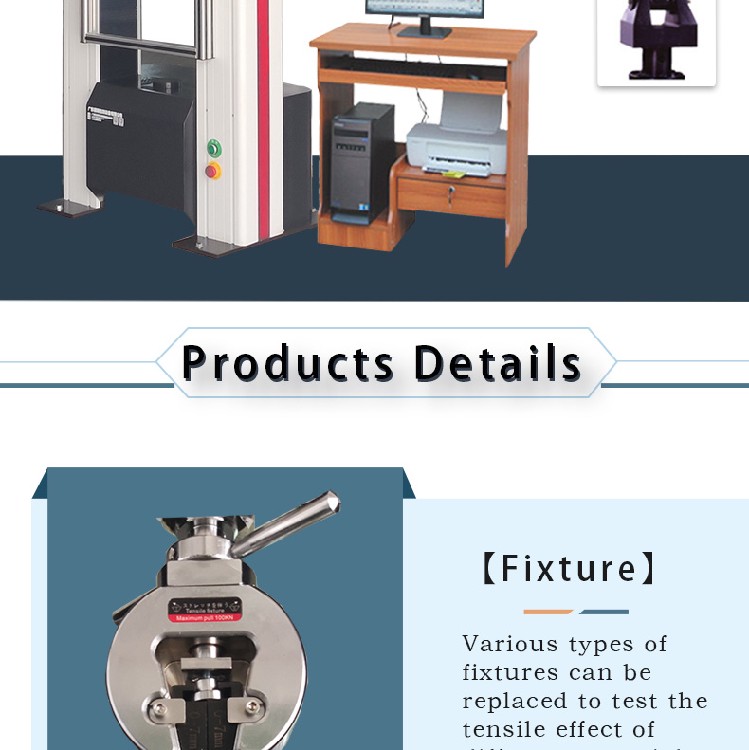

- Degree of Automation: Modern machines typically offer high levels of automation, including automatic loading, unloading, and execution of test programs, which can significantly reduce human error and improve efficiency.

- Data Analysis Software: High-quality software not only simplifies the operation but also provides robust data processing and report generation capabilities for subsequent quality assessment.

4. Additional Functions and Expandability

- Environmental Simulation: If tests need to be conducted under non-standard conditions (such as high or low temperatures, humidity control), consider whether the machine includes environmental chambers.

- Modular Design: Opt for a modular system that supports future upgrades and expansion, such as adding new test modes or changing fixture types.

5. Brand Reputation and After-sales Service

- Manufacturer Reputation: Prioritize well-known brands, as these companies often provide better product quality and technical support.

- After-sales Support: Good after-sales service is crucial, covering installation, training, maintenance, and repair services.

6. Budget Considerations

- Initial Investment Cost: While high-performance equipment may have higher upfront costs, consider the long-term benefits in terms of reduced maintenance expenses and increased efficiency.

- Total Cost of Ownership (TCO): Besides the purchase price, factor in operational costs, consumables, and potential downtime losses.

7. Space and Facility Constraints

- Laboratory Space: Ensure your lab has sufficient space to accommodate the selected testing machine and any auxiliary equipment.

- Power Supply and Other Infrastructure: Verify that existing facilities meet the equipment’s requirements, such as power voltage and grounding conditions.

8. Regulations and Certifications

- Compliance: Ensure the selected equipment complies with relevant international and national standards (e.g., ISO, ASTM, DIN), which is critical for ensuring the validity and comparability of test results.

By following these steps, you can scientifically and rationally select the most suitable computer-controlled dual-column tensile testing machine for quality acceptance, providing solid technical assurance for product quality and safety. Maintaining close communication with suppliers to obtain professional advice and support is also an essential part of successful procurement.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.