Welcome!

Dust Resistance Tester with 999H Programmable Test Time

Product Description

Dust Test Chamber Parameter

| Item | Specification |

| Internal dimension | 800W*800D*800Hmm |

| External dimension | 1300W*1000D*1700Hmm |

| Test sample | Size W20cm- L30cm-D15cm, weight 0.5kg |

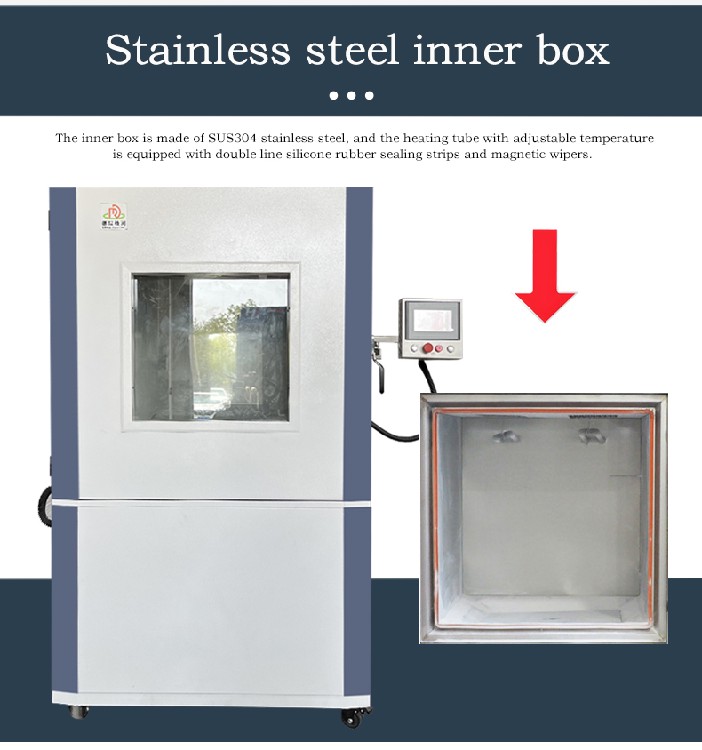

| Chamber material | SUS304 Stainless steel |

| Specifications of square mesh sieve | Mesh hole 75um, mesh metal wire diameter 50um |

| Talcum powder amount | 2kg/ m³ |

| Airflow speed | No more than 2m/s |

| Door | Left open door with tempered glass door |

| Controller | PLC Touch Screen controller, programmable to set as below cycle:a. Blowing dust time (Stop/Blow) m/sb. Cycle time: can be adjustedc. Pre-set test time: 0s ~99m99s |

| Vacuum system | Pressure gauge, air filter, Pressure regulating FRL, connecting pipe, Vacuum pump |

| Vacuum pump capacity | 60-600 L/H |

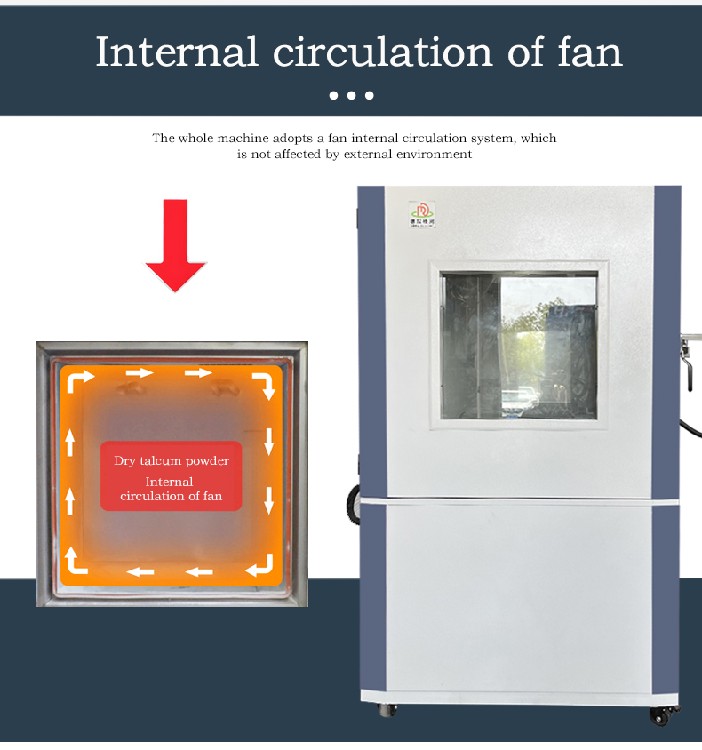

| Fan | Centrifugal fan |

| Safety protection devices | Meter over-temperature function, Phase shortage protection, Power short-circuit protection |

When selecting the appropriate test standard for a dust tester, several factors need to be considered, including the type of product, the environment in which it will be used, and industry requirements. The following are some suggestions for selecting a test standard:

1. Product type and protection level

Electronic products: usually require a higher dust protection level, such as IP5X or IP6X, to ensure the normal operation of the equipment in harsh environments.

Automotive parts: such as parts in the engine compartment, lights, instrument panels, etc., need to choose the appropriate level of protection according to the actual use of the environment, usually IP5X or IP6X.

Industrial equipment: equipment that may encounter a large amount of dust and particles in the production process, requiring a higher level of dust protection.

2. Use environment and test conditions

Dry environment: If the product is mainly used in dry and less dusty environments, a lower dust protection rating, such as IP4X, can be selected.

Harsh environment: such as deserts, construction sites and other dusty environments, you need to choose a higher level of dust protection, such as IP6X.

Special environments: such as medical equipment used in operating rooms and other environments, need to have good dustproof performance.

3. Industry standards and regulatory requirements

International standards: such as IEC 60529 is a widely used international standard for dustproof testing, applicable to a variety of electronic equipment and products.

National standards: e.g. GB/T 4208-2017 is a national standard in China, which stipulates the classification and test methods for enclosure protection level.

Industry-specific standards: e.g. the automotive industry may have specific dust-proof test standards, such as ISO 20653.

4. Test Purpose and Requirements

Quality control: If the purpose of the test is to ensure product quality and reliability, a test method that complies with industry standards may be selected.

Product certification: Some products may require specific certification, such as IP rating certification, which requires the selection of the appropriate test standards.

5. Test equipment and resources

Equipment capacity: Ensure that the selected test standard matches the capacity of the test equipment, such as whether the equipment is able to simulate the required environmental conditions.

Test Cost: Consider the cost and time of testing and select the appropriate test standard to optimize the testing process.

6. Standard Updates and Latest Requirements

Standards update: Regularly monitor the update of relevant standards to ensure that the test methods meet the latest industry requirements.

By considering the above factors, the most appropriate dust test standard can be selected for a specific product to ensure the accuracy and reliability of the test results.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.