Welcome!

ASTM B392 99.95% pure niobium bars

- T/T L/C D/P D/A MoneyGram Credit Card

- Shanghai port Tianjin port

- 100 Ton / Tons per Month

Basic Info

| Application | Industrial | Brand Name | XLT | Diameter | dia 3.0-110mm |

|---|---|---|---|---|---|

| Grade | niobium, Nb1, Nb2, FNb1, FNb2 | Length | ≤6000mm | Model Number | XLT-NB01 |

| Place of Origin | Shaanxi, China | Shape | Round | Technique | Forged |

| Weight | volume x8.57g/cm3 | ||||

Product Description

Product Description

Niobium bar for niobium products

Specifications

Niobium bar

ASTM B 393-98

Size:Thk up to 0.1mm max*W up to 200mm max.*L

Best price+High quality+Prompt delivery!

Our company holds Tantalum ,Niobium as the dominant products in the scope of rare metal new materials, including many sorts and grades of their metals, sheet, tube, wire ,rod ,crucible , target ,alloy and so on.

Niobium is an associated metal of tantalum ,characterized in high strength ,high conductivity ,resistance to corrosion by liquid base metals ,section with low neutron capture ,etc ,widely used for steel ,ceramics ,electronics ,nuclear energy industries and superconductor technology.

Product Name: niobium alloy sheet for niobium products

Designation:RO4210-2,RO4261-4,C-103 Nb-Hf-Ti Alloy,Cb752 Nb-W-Zr Alloy;

Standard:ASTMB393;

Purity:Nb>99.95%;

State:Annealed(M) or Non-Annealed(Y)

Size:

Thickness(mm) | Width(mm) | Length(mm) |

| 0.10~0.20 | 30≤W≤200 | 30≤L≤1500 |

| 0.2~1.0 | 30≤W≤300 | 30≤L≤1500 |

| 1.0~10.0 | 30≤L≤1000 | 30≤L≤2000 |

| ≥10.0 | 30≤L≤1000 | 30≤L≤1000 |

1, Chemistry

Designation | RO4210-2 | RO4261-4 | C-103 | Cb752 | |

Impurities (%) | Zr | 0.02 | 0.8~1.2 | 0.7 | 2.0~3.0 |

Ti | 0.002 | 0.02 | 0.7~1.3 | 0.2 | |

C | 0.01 | 0.01 | 0.015 | 0.015 | |

N | 0.015 | 0.01 | 0.015 | 0.01 | |

O | 0.015 | 0.015 | 0.023 | 0.02 | |

H | 0.001 | 0.0015 | 0.002 | 0.0015 | |

Ta | 0.10 | 0.10 | 0.5 | 0.5 | |

Fe | 0.005 | 0.005 | - | - | |

Si | 0.005 | 0.005 | - | - | |

W | 0.03 | 0.03 | 0.5 | 9.0~11.0 | |

Ni | 0.005 | 0.005 | - | - | |

Mo | 0.010 | 0.01 | - | - | |

Cr | 0.002 | 0.002 | - | - | |

Hf | - | - | 9.0~11.0 | 0.2 | |

Nb | Bal | Bal | Bal | Bal | |

2,Tollerance

Thickness(mm) | Tollerance of Thickness(mm) | Width(mm) | Tollerance of Width(mm) | Length | Tollerance of Length (mm) |

>0.1~0.2 | ±0.015 | 30~200 | ±2.0 | 30≤L≤1500 | ±3.0 |

>0.2~0.3 | ±0.02 | 30~300 | ±3.0 | 30≤L≤1500 | ±3.0 |

>0.3~0.5 | ±0.03 | 30~300 | ±3.0 | 30≤L≤1500 | ±3.0 |

>0.5~0.8 | ±0.04 | 30~300 | ±3.0 | 30≤L≤1500 | ±3.0 |

>0.8~1.0 | ±0.06 | 30~300 | ±3.0 | 30≤L≤1500 | ±3.0 |

>1.0~1.5 | ±0.08 | 30~1000 | ±4.0 | 30≤L≤2000 | ±3.0 |

>1.5~2.0 | ±0.12 | 30~1000 | ±4.0 | 30≤L≤2000 | ±3.0 |

>2.0~3.0 | ±0.18 | 30~1000 | ±4.0 | 30≤L≤2000 | ±3.0 |

>3.0~4.0 | ±0.18 | 30~1000 | ±4.0 | 30≤L≤2000 | ±3.0 |

>4.0~6.0 | ±0.20 | 30~1000 | ±4.0 | 30≤L≤2000 | ±3.0 |

Note:The tolerance should be determined by the seller and buyer for special size products. | |||||

3,Physical Properies

Designation | State | Thickness (mm) | Tensile Strength σb /MPa | Elong A / % |

RO4210-2 | Annealed | 0.1~0.25 | ≥196 | ≥25 |

Annealed | ≥0.25~0.5 | ≥196 | ≥25 | |

Annealed | ≥0.5 | ≥196 | ≥25 |

first-classs production equipment

Recommended Products

Recently Viewed

Contact Us

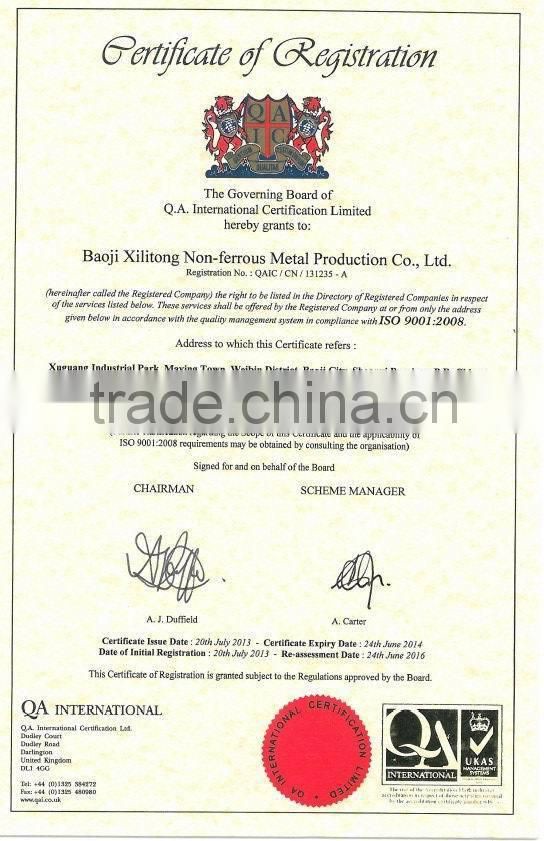

Baoji Xilitong Non-Ferrous Metal Production Co., Ltd.