Welcome!

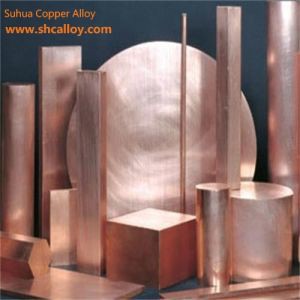

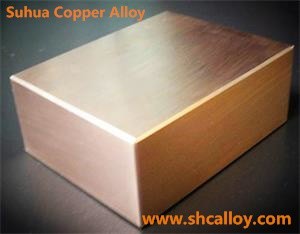

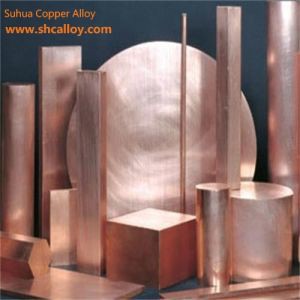

China Best Chromium Copper Alloy for Spot Welder

Product Description

Chromium copper has begun to replace beryllium copper as a general mold material in the mold industry due to its conductive and thermal conductivity, hardness, wear resistance and explosion resistance, and superior price compared with beryllium copper mold material. For example, shoe sole molds, plumbing molds, plastic molds that generally require high smoothness, connectors, guide wires, and other products that require high strength wires.

It has high strength and hardness, electrical conductivity and thermal conductivity, good wear resistance and wear resistance. After aging treatment, the hardness, strength, electrical conductivity and thermal conductivity are significantly improved, and it is easy to weld. It is widely used for motor commutator, spot welding machine, seam welding machine, electrode for butt welding machine, as well as other parts requiring strength, hardness, conductivity and conductivity at high temperature. The electric spark electrode can be used to produce an ideal mirror surface, with good upright performance. It can achieve the effect that is difficult to achieve with pure red copper such as flaking. It is good for difficult to machine materials such as tungsten steel.

Recommended Products

Recently Viewed

Contact Us

Suhua Copper Alloy Co., Ltd.