Welcome!

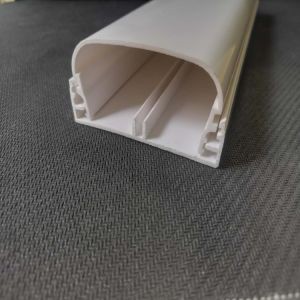

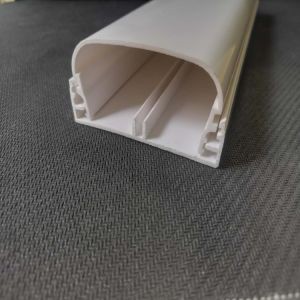

Automatic CNC Plastic Injection Mould Part for Machine Rubber Parts

Product Description

The closed rubber mixer is mainly used for rubber molding and mixing. It has one more internal mixing chamber than an open rubber mixer. After the raw rubber and compounding agent are loaded into the mixing chamber from the feeding hopper, the material door is closed, and the top bolt of the pressing device is pressed down. The two rotors in the mixing chamber rotate in opposite directions at different or the same speed. The loaded rubber is subjected to continuous stirring, folding, and intense kneading between the rotors, as well as between the rotors and the internal mixing chamber, resulting in oxidative chain breakage and increased plasticity. At the same time, the rubber material is dispersed and uniformly mixed due to shearing action, thereby achieving the purpose of rubber mixing.

The open type rubber mixer is mainly used for heat refining, sheeting, breaking, molding, and mixing of rubber. It consists of a roller, a roller bearing, a roller pitch adjustment device, an emergency braking device, a frame, a base, a transmission device, and a heating and cooling system. The working principle of an open rubber mixing machine is that raw rubber or rubber material is pulled into the roller gap by friction between two opposing rotating rollers at different speeds, and is subjected to intense shearing and extrusion to increase plasticity. This double roller open type rubber mixing machine has been used in production since 1826. Its structure is relatively simple, and it is still widely used in modern times.

Recommended Products

Recently Viewed

China Custom Injection Molding Mold Plastic & Rubber Machinery Parts

China Custom Injection Molding Mold Plastic & Rubber Machinery Parts Automatic CNC Plastic Injection Mould Part for Machine Rubber Parts

Automatic CNC Plastic Injection Mould Part for Machine Rubber Parts Automatic Plastic Injection Molding Mold Plastic & CNC Rubber Machinery Parts

Automatic Plastic Injection Molding Mold Plastic & CNC Rubber Machinery Parts Conveyor

Conveyor Factory supply Plastic Injection Molding Mold Plastic & CNC Rubber Machinery Parts

Factory supply Plastic Injection Molding Mold Plastic & CNC Rubber Machinery Parts

Contact Us

Tongxiang Juli Plastic Co., Ltd.