Welcome!

High Quality spray graphite lubricant Graphite Wear Resistance Metal Anti-Wear Gear Grease

Product Description

Graphite lubricants perform well under high temperature and high pressure conditions, while traditional lubricants may degrade or evaporate. The heat resistance of graphite enables it to withstand extreme temperatures without losing its lubrication ability, making it a reliable choice for demanding industrial applications.

One of the main advantages of graphite lubricants is that they can provide lubrication without the need for traditional wet oil or grease. The drying characteristics of graphite lubricants make them highly suitable for environments where liquid lubricants may attract dust, dirt, or pollutants, thereby increasing maintenance requirements and potential performance issues.

Graphite lubricants are suitable for various materials and surfaces, including metals, ceramics, plastics, etc. This enables it to be widely applied in different industrial fields, meeting the lubrication needs of different equipment and processes. Graphite lubricants have excellent anti-wear performance, which can effectively reduce wear and friction during equipment operation, protect the surface of the equipment from damage, and improve the overall performance and service life of the equipment.

The characteristics of graphite lubricants

Environmental protection and safety

high temperature stability

Good lubrication performance

Graphite lubricant, as an efficient and multifunctional lubricating material, plays an important role in many industrial fields. Its unique physical and chemical properties make graphite lubricants an indispensable lubrication solution in many mechanical equipment and process processes. This article will provide a detailed introduction to the characteristics, application areas, and advantages of graphite lubricants, helping readers better understand this excellent lubricating material.

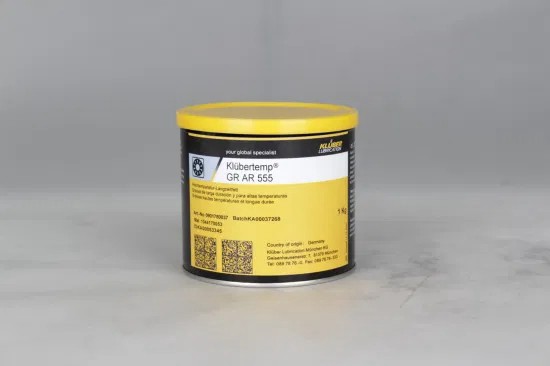

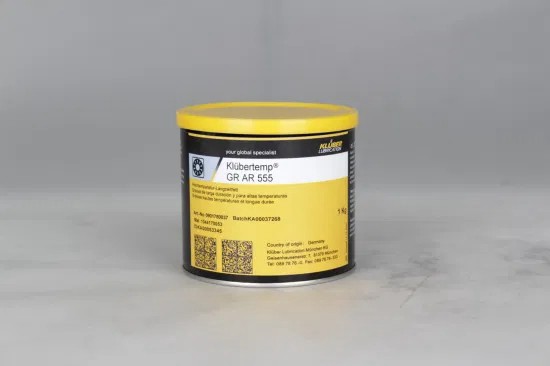

Recommended Products

Recently Viewed

High Quality graphite lubricants Graphite Wear Resistance Metal Anti-Wear Gear Grease

High Quality graphite lubricants Graphite Wear Resistance Metal Anti-Wear Gear Grease High Quality graphite spray lubricant Graphite Wear Resistance Metal Anti-Wear Gear Grease

High Quality graphite spray lubricant Graphite Wear Resistance Metal Anti-Wear Gear Grease New High-Efficiency spray graphite lubricant Graphite Lubricant for Graphite Battery

New High-Efficiency spray graphite lubricant Graphite Lubricant for Graphite Battery No. 32, No. 46 and No. 68 anti-wear hydraulic oil

No. 32, No. 46 and No. 68 anti-wear hydraulic oil 100% Original Oil graphite spray lubricant Graphite Lubricant for Graphite Battery

100% Original Oil graphite spray lubricant Graphite Lubricant for Graphite Battery

Contact Us

HEBEI XINGSHI IMPORT AND EXPORT CO., LTD.