Welcome!

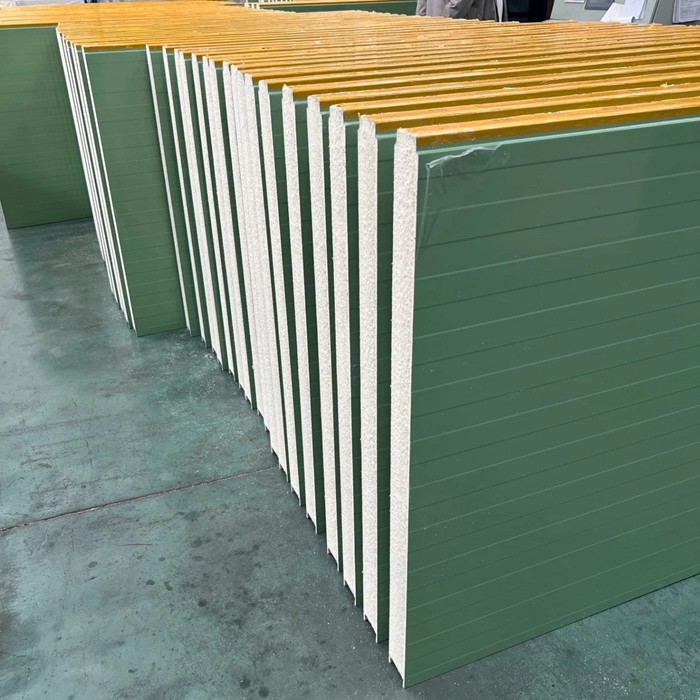

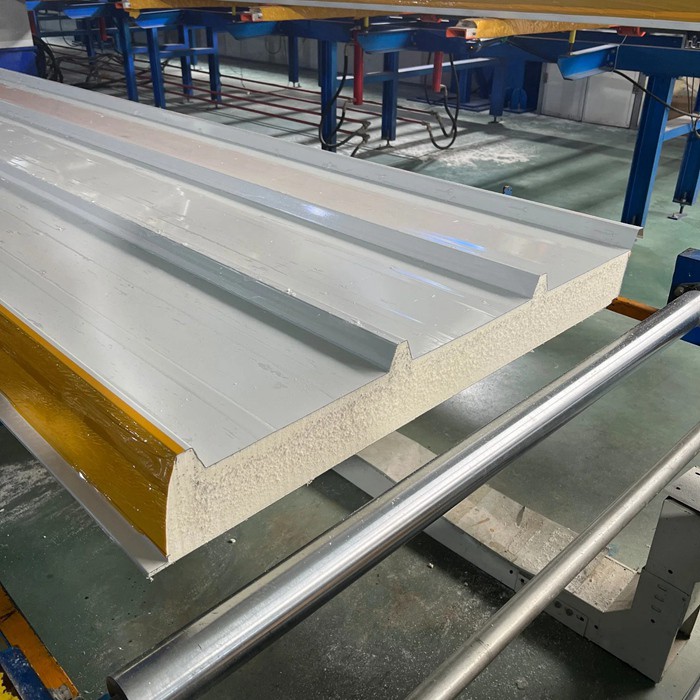

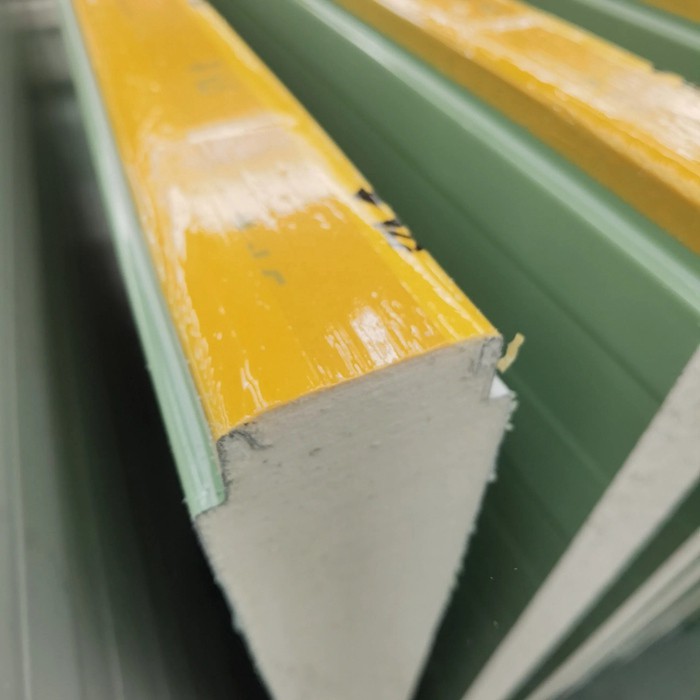

Customized Insulated Wall Roof Boards EPS/Glasswool Waterproof Sandwich Panels for Internal and External Wall

Product Description

Insulation sandwich panels are also suitable for places that require strict temperature control, such as cold storage, hospitals, laboratories, etc. In these special occasions, the excellent insulation performance of insulated sandwich panels can ensure the stability of indoor temperature and meet specific needs. The metal sheet surface of the insulation sandwich panel can be treated with various spraying, embossing, and other treatments, presenting rich colors and textures that can blend with different architectural styles. Meanwhile, its sturdy structure also ensures the aesthetics and durability of the building.

Core material is a key part of insulation sandwich panels, commonly used include polystyrene, rock wool, polyurethane, etc. These materials have good thermal insulation performance, which can effectively reduce heat transfer and reduce building energy consumption. The use of insulated sandwich panels helps to reduce building energy consumption and carbon emissions, in line with the concepts of green building and sustainable development.

Sandwich panels typically consist of two layers of metal sheets (such as steel plates, aluminum plates, etc.) and one layer of core material, which can be materials such as polystyrene, rock wool, polyurethane, etc. This sandwich structure allows the sandwich panel to have both the strength and rigidity of a metal plate, as well as the insulation, sound insulation, fire resistance, and other properties of the core material.

Sandwich panels, as an efficient and multifunctional building material, have been widely used in the construction industry in recent years. It meets the multiple needs of modern architecture for aesthetics, durability, environmental protection, and energy efficiency with its unique structural design and excellent performance characteristics.

Recommended Products

Recently Viewed

Packaged container houses for export from Tianjin Port, Insulated folding container houses for export

Packaged container houses for export from Tianjin Port, Insulated folding container houses for export Exported container movable houses in Tianjin Port. Wholesale sale of packed container houses and folding container houses

Exported container movable houses in Tianjin Port. Wholesale sale of packed container houses and folding container houses Export rock wool boards from Tianjin Port and export rock wool color steel houses for living

Export rock wool boards from Tianjin Port and export rock wool color steel houses for living Sell color steel houses and prefabricated panel houses. Export container mobile houses for living and office use

Sell color steel houses and prefabricated panel houses. Export container mobile houses for living and office use Color steel prefabricated houses for export to Africa from Tianjin Port, Export container houses

Color steel prefabricated houses for export to Africa from Tianjin Port, Export container houses

Contact Us

Shandong Hark Steel Material Co., Ltd.