Welcome!

Guangdong Texchain Textile Technology Co., Ltd

Main products: Pretreatment Agents ,Dyeing Auxiliaries,printing assistant,Functional Finishing Agent,Soft finishing agent,Cowboy washing agent,AMINO SILICONE OIL,HYDROPHILIC SILICONE OIL,FLAKE,LEVELING AGENT,FIXER,Fluorine free waterproofing agent,WET ABSORPTION FAST DRY FINISHING AGENT,STIFFENING AGENT,WET ABRASION FASTNESS IMPROVING AGENT,Enzymes

Oil based fluorine free waterproof agent

Product Description

Technical indicators

Component: Polyurethane polymer

Appearance: Colorless to light yellow transparent liquid

Suitable for coating and finishing of various fabrics and leather.

Product performance

1. Strong adhesion to fabrics and good film-forming properties;

2. It has excellent anti siphon performance;

3. Anti fouling properties;

4. Excellent water repellency, impermeability, and hydrolysis resistance;

5. This product is fluorine free and environmentally friendly, and does not contain PFOS or PFOA.

Usage:

It can be diluted with appropriate solvents and applied to independent equipment equipped with local exhaust or air handling units, such as impregnation

Liquid roll and dip rolling treatment or industrial spray. Suitable solvents are hydrocarbons, such as isopropyl derivatives of petroleum distillates or paraffin wax

N-Butyl acetate.

Reference process

1. Recommended formula and process flow for wet impregnation

PU resin 100

Fluorine free waterproofing agent 0.2-0.4

Color paste 5

DMF 250-350

Non woven fabric → immersion solution → solidification (20-25% DMF, temperature 25-35 ℃) → water washing → drying (120-130 ℃, 30 minutes)

2. Recommended formula and process flow for wet coating

PU resin 100

Additives 2-4

Color paste 10

Fluorine free waterproofing agent 0.2-0.4

DMF 250-350

Non woven fabric → containing immersion solution → extrusion roller (0.15-0.25MP) → hot roller (semi dry, with a tying rate of 30% -45%, 60-70 ℃) → coating

Layer liquid → Solidification (20-25% DMF, temperature 25-35 ℃) → Water washing

3. Recommended formula and process flow for dry direct immersion

PU resin 100

Additives 1-2

Fluorine free waterproofing agent 1-1.5

Toluene 20

Polyester → Water removal → Lower layer coating → Upper layer coating → Drying (130 ℃, 3 minutes)

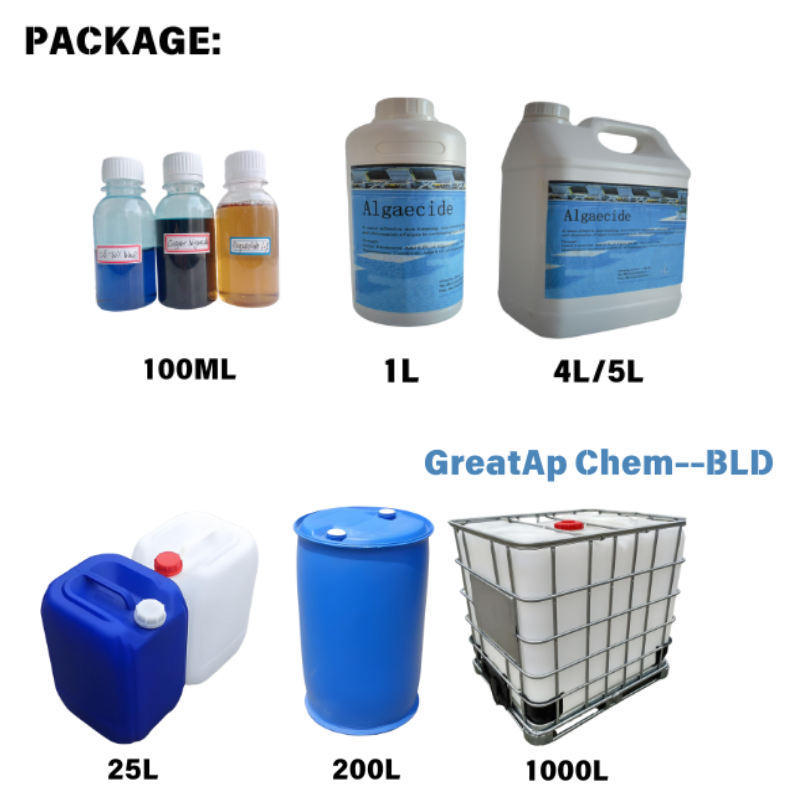

Packaging, storage and transportation

125KG/barrel, sealed and stored in a cool and dry place, with a storage period of 6 months.

Recommended Products

Recently Viewed

Selling Hot 2-Methylimidazole 2-Methyl-1h-Imidazole 693-98-1 C4H6N2

Selling Hot 2-Methylimidazole 2-Methyl-1h-Imidazole 693-98-1 C4H6N2 CAS:127-09-3 Industrial grade Sodium Aceta Leather auxiliaries sewage treatment preservative

CAS:127-09-3 Industrial grade Sodium Aceta Leather auxiliaries sewage treatment preservative Perfumes, cosmetics, toilet preparations, and industrial products for flavor and fragrance.

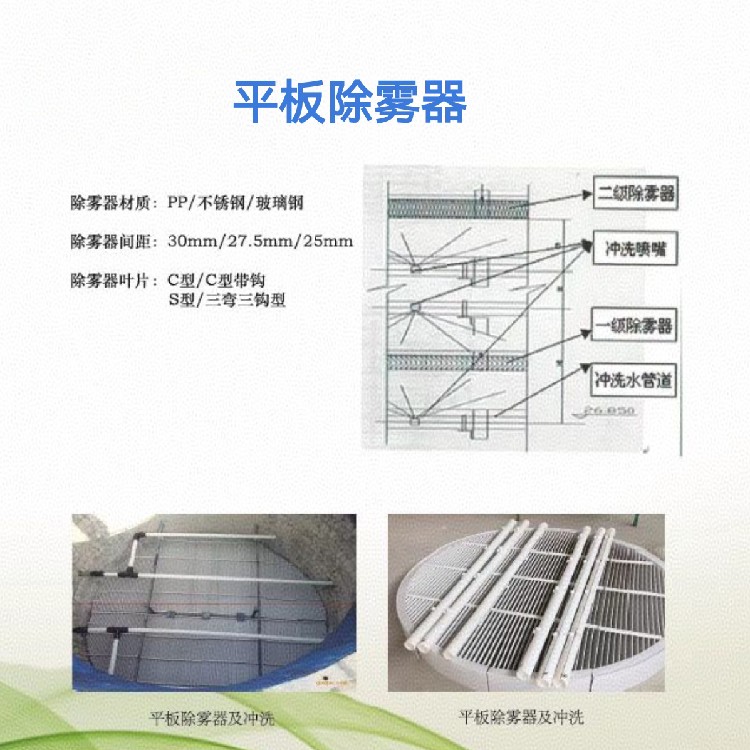

Perfumes, cosmetics, toilet preparations, and industrial products for flavor and fragrance. Horizontal ridge tubular and flat-plate demisters

Horizontal ridge tubular and flat-plate demisters Imidazole-Epichlorohydrin Copolymer Ime Brightener in Alkaline Zinc and Zinc Alloy Plating CAS No. 68797-57-9

Imidazole-Epichlorohydrin Copolymer Ime Brightener in Alkaline Zinc and Zinc Alloy Plating CAS No. 68797-57-9

Contact Us

Guangdong Texchain Textile Technology Co., Ltd