Welcome!

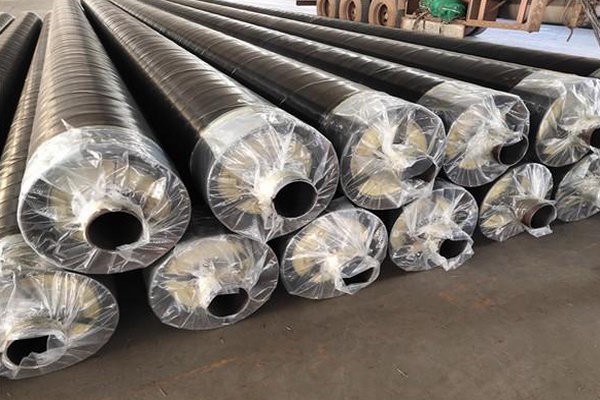

China Supplier Corrugation 150mm X 50mm Structure Plate Corrugated Pipe Culvert of Tunnels, Bridges and Culverts.

Product Description

The metal culvert adopts standardized design, with a short production cycle and stable and reliable quality. Meanwhile, standardized design also facilitates quality control and management during the construction process. The use of metal culverts reduces the demand for traditional building materials such as cement, yellow sand, stones, etc., and reduces the consumption of natural resources. Meanwhile, metal culverts can be recycled and reused, meeting environmental protection requirements.

With the increasing requirements for environmental protection, efficiency, and quality, the application prospects of metal culverts will be even broader. Metal culverts, with their unique structure and advantages, are playing an increasingly important role in modern transportation infrastructure construction. On site installation of metal culverts does not require the use of large equipment, reducing construction difficulty and cost.

The construction cost of metal culverts is relatively low, especially in areas lacking sand and gravel materials or with low foundation bearing capacity, and their advantages are more significant. Metal culverts are not only widely used in the construction of transportation infrastructure such as highways and railways, but also in the reinforcement, emergency rescue, and communication engineering of bridges. Metal culverts are constructed using assembly methods, which can significantly shorten the construction period compared to traditional reinforced concrete culverts.

Metal culverts, also known as metal corrugated culverts or steel corrugated pipe culverts, are a special type of culvert structure mainly used for culverts (pipes) in various engineering projects such as highways, railways, small bridges, passages, retaining walls, as well as mine and roadway retaining wall support. The following is a detailed introduction to the main characteristics and composition of metal culverts:

Recommended Products

Recently Viewed

Contact Us

Qingdao Quanlong Metal Materials Co., Ltd.