Welcome!

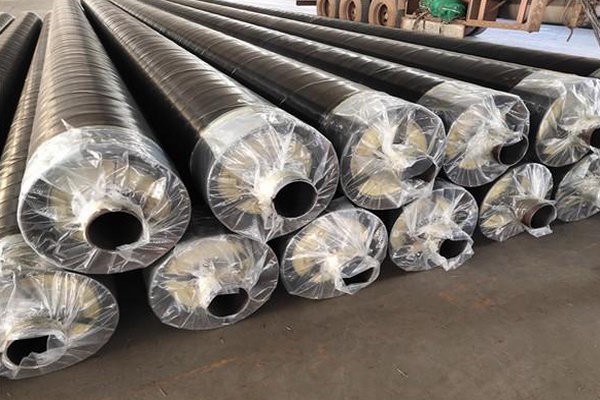

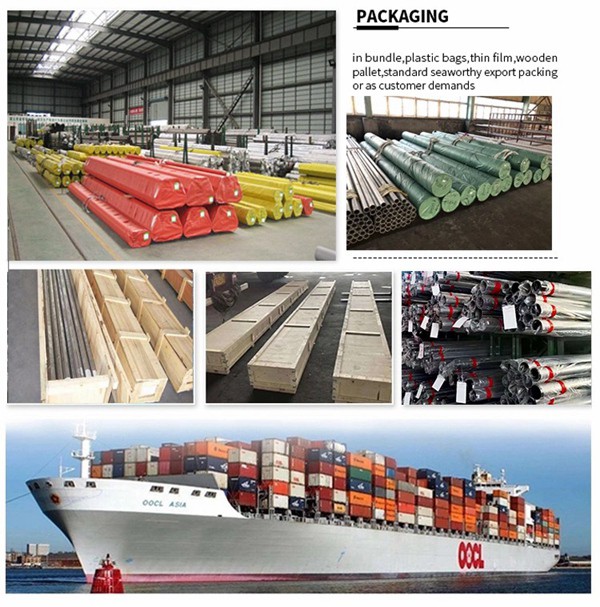

Factory Price Stainless Steel Welded Pipe Seamless Coil Tube

Product Description

The application fields of stainless steel pipes are very extensive, including multiple industries such as petrochemicals, food processing, pharmaceutical manufacturing, construction, and environmental protection. In the petrochemical industry, stainless steel pipes are often used to transport various corrosive media; In the construction industry, stainless steel pipes are used to make structural supports, decorative materials, etc; In the field of environmental protection, stainless steel pipes are used to manufacture sewage treatment equipment, exhaust gas treatment equipment, etc.

Stainless steel pipes can maintain stable performance in various corrosive media and are not prone to rusting or other forms of corrosion. Stainless steel pipes usually have high strength, hardness, and toughness, and can withstand large loads and impacts. The surface of stainless steel pipes is smooth and bright, easy to clean and maintain, and can maintain a beautiful appearance for a long time. Stainless steel pipes can be processed through various methods such as cutting, welding, and bending, making it easy to manufacture fittings of various shapes and sizes.

Although stainless steel pipes have excellent corrosion resistance, maintenance and upkeep are still necessary during use. Regularly clean the surface of the pipeline to remove attached dirt and impurities; For parts that have already rusted, timely repair or replacement should be carried out; During storage and transportation, contact with corrosive substances should be avoided to avoid damage to pipelines.

In the field of environmental protection, stainless steel pipes are used to manufacture various sewage treatment equipment, exhaust gas treatment equipment, etc. Its excellent corrosion resistance and mechanical properties enable these devices to operate stably for a long time, making important contributions to the environmental protection industry. The processing and installation of stainless steel pipes are relatively simple and convenient. It can be processed through various methods such as cutting, welding, and bending to meet the needs of different occasions. During the installation process, various methods such as flange connection, socket connection, and threaded connection can be used to ensure the firmness and reliability of pipeline connections.

Recommended Products

Recently Viewed

Contact Us

Shandong Hongtai Metal Products Co., Ltd.