Welcome!

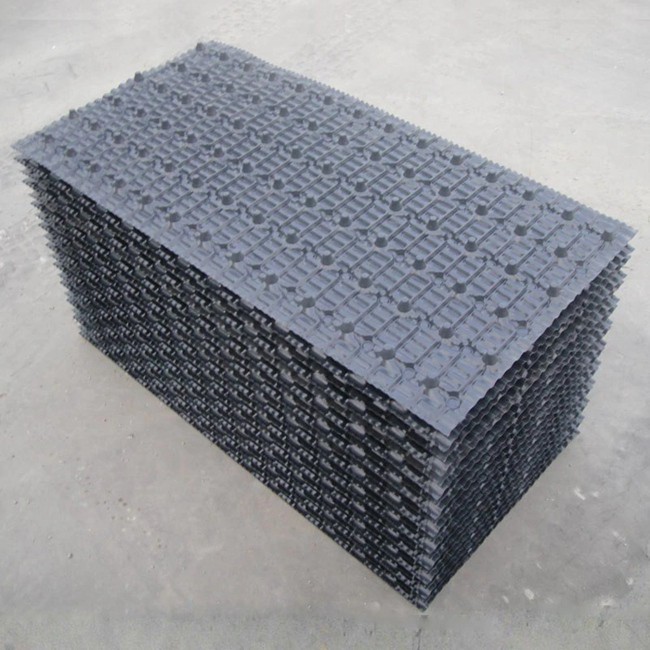

China Supplier Various Cooling Tower PVC Film Filler

Product Description

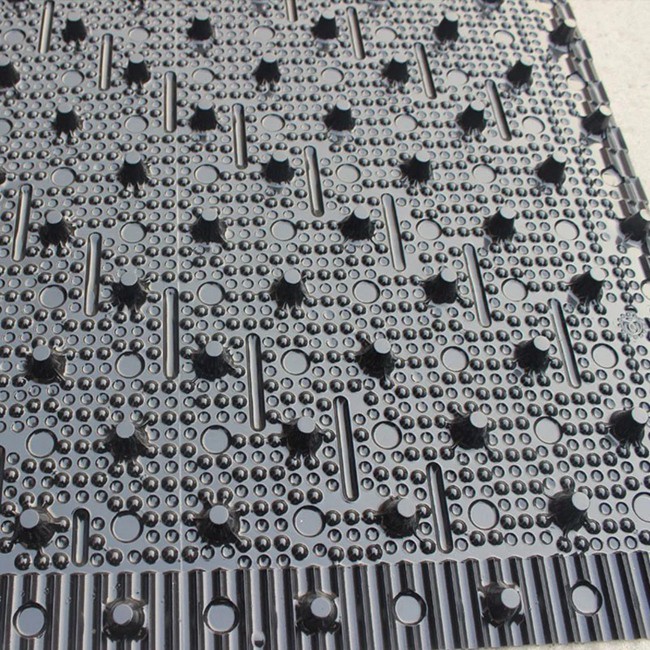

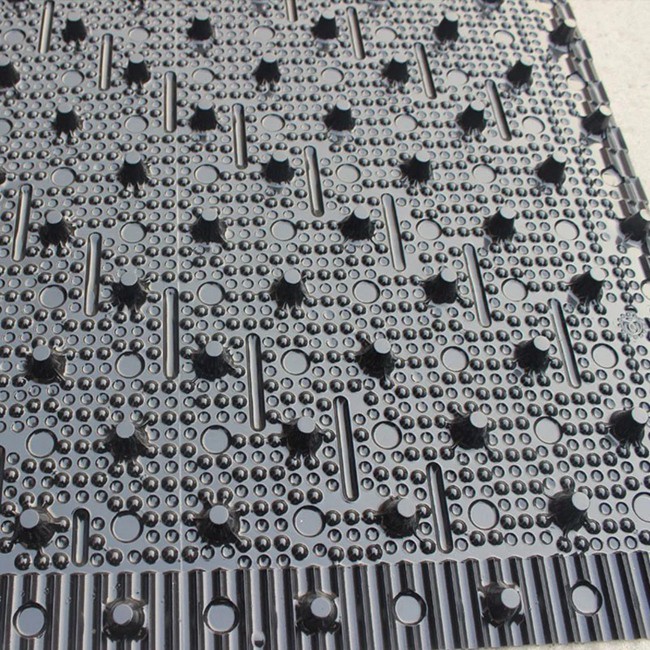

There are various types of PVC cooling tower packing, such as plastic grid packing, plastic film packing, and plastic spherical packing. These different types of fillers have different characteristics and applicable scenarios, which can meet the needs of different cooling towers. For example, plastic grid packing is suitable for cooling towers with high evaporation rate and cooling effect; Plastic film packing is suitable for use in cooling towers with high levels of dust and easy accumulation of dust in the environment; Plastic spherical fillers are known for their high porosity, large surface area, and high efficiency.

PVC material has good chemical stability and can resist the erosion of various chemicals. During the operation of cooling towers, it is often necessary to handle various chemicals and high-temperature fluids, so the corrosion resistance and high-temperature resistance of the packing are crucial. PVC filler can operate stably for a long time in such an environment, ensuring the performance and lifespan of the cooling tower.

In addition to the aforementioned fields, PVC fillers are also widely used in various industries such as construction, packaging, and automotive manufacturing. For example, in the field of construction, PVC fillers can be used as waterproof materials and soundproofing boards; In the packaging industry, it can be used as a film and sealing material; In the field of automobile manufacturing, PVC fillers can be used to make components such as interior decorative strips and cable sheaths.

In the field of air treatment, PVC fillers also play an important role. For example, in air filters, PVC packing can effectively remove pollutants from the air and improve air quality. Its good breathability and ventilation performance enable air to pass through the packing layer more smoothly, fully contact with other media in the filter, and improve filtration efficiency.

PVC fillers are known for their excellent chemical inertness, corrosion resistance, and wear resistance. It can maintain stable performance in various harsh environments and withstand long-term corrosion from chemical substances and impact from high-temperature fluids. In addition, PVC fillers also have excellent breathability and ventilation performance, thanks to their corrugated or hexagonal structure, which can significantly increase the breathable area of the filler bed and improve the efficiency of heat and mass exchange.

Recommended Products

Recently Viewed

Best Price Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower

Best Price Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower China Supplier Mini Closed Water Cooling Tower Price

China Supplier Mini Closed Water Cooling Tower Price Best Price Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower

Best Price Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower Best Price Mini Closed Water Cooling Tower Price

Best Price Mini Closed Water Cooling Tower Price Hot Sale Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower

Hot Sale Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower

Contact Us

WEIFANG HENG AN IMP & EXP CO., LTD.