Welcome!

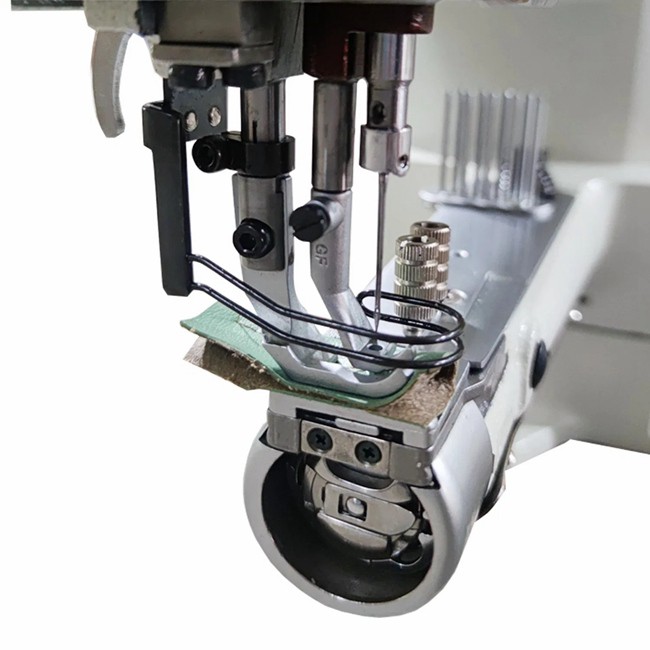

High Speed Direct Drive Computerized Lockstitch Stepping Industrial Sewing Machine

Product Description

The computer sewing machine uses an electrically controlled stepper motor to control the sewing action. After the power is turned on, the motor starts to run, and the controller sends instructions to the motor drive mechanism to control its forward and reverse rotation, thereby achieving the up and down movement of the needle and synchronously controlling the feed of the fabric. This operation control based on an electrically controlled stepper motor closely correlates the sewing speed with the motor operating speed, achieving precise and efficient sewing operations.

Industrial sewing machines have also promoted the upgrading and transformation of the entire industry chain. With the popularization and application of automation and intelligent technology, the textile and garment industry is gradually developing towards digitalization, networking, and intelligence, injecting new vitality into the sustainable development of the industry. As the core production equipment in the textile and garment industry, industrial sewing machines play an important role in promoting industry progress and upgrading. With the continuous advancement of technology and changing market demands, we have reason to believe that industrial sewing machines will play a more important role and contribute in the future.

In the mid to low end sewing machine products, the world sewing machine industry has completed its transfer to China, and the industrial transfer is gradually extending to mid to high end products. In the Chinese market, there is a wide variety of types and brands of sewing machines available, meeting the needs of different consumers. Sewing machines, as an important sewing tool, play a crucial role in fields such as textiles, clothing, and home furnishings. With the continuous advancement of technology and the diversification of consumer demands, the functions and types of sewing machines are also constantly enriched and improved.

The working principle of a sewing machine mainly includes four steps: thread transfer, pinhole formation, stitch formation, and fabric transfer. The sewing machine provides two threads, upper and lower, through a spool, which enter the machine body through a guide, tensioner, and spool to ensure smooth thread transfer. The sewing machine forms needle holes through the reciprocating motion of the upper and lower needles. When the needle moves downwards, the upper needle passes the thread through the fabric through the thread plate and the lower needle eye plate, forming a needle eye. The formation of a trace depends on the interweaving of online and offline lines. When the upper needle passes down through the fabric, it will thread the upper thread through the fabric and interweave with the lower thread in the needle eye, forming a stitch. The sewing machine transfers fabric through the lower hem, upper hem, and gear transmission. When the gear rotates, the lower swing and upper swing move alternately, conveying the fabric forward.

Recommended Products

Recently Viewed

Factory Supplier Direct Drive Computerized Lockstitch Industrial Sewing Machine

Factory Supplier Direct Drive Computerized Lockstitch Industrial Sewing Machine High Speed Direct Drive Direct Drive Computerized Lockstitch Industrial Sewing Machine

High Speed Direct Drive Direct Drive Computerized Lockstitch Industrial Sewing Machine New Design Touch Panel Computerized Lockstitch Sewing Machine with Speaking

New Design Touch Panel Computerized Lockstitch Sewing Machine with Speaking High Quality Industrial Direct Drive Auto Trimmer Sewing Machine

High Quality Industrial Direct Drive Auto Trimmer Sewing Machine High Speed Direct Drive Computerized Lockstitch Sewing Machine

High Speed Direct Drive Computerized Lockstitch Sewing Machine

Contact Us

KUN SHAN EAGLE TECHNOLOGY CO.,LTD.