Welcome!

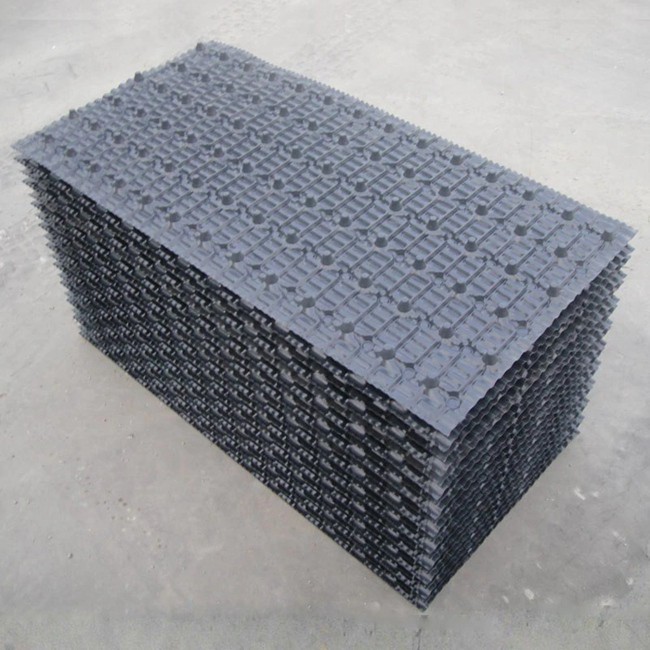

China Supplier Various Cooling Tower PVC Film Filler

Product Description

With the continuous progress of science and technology and the continuous development of industrial technology, the application scope of PVC fillers will continue to expand. In the future, PVC fillers are expected to leverage their unique advantages in more fields, providing efficient and reliable solutions for the heat dissipation, filtration, and purification needs of various industries. Meanwhile, with the increasing awareness of environmental protection and the deepening of sustainable development concepts, the environmental friendliness of PVC fillers will also become one of the important directions for their future development.

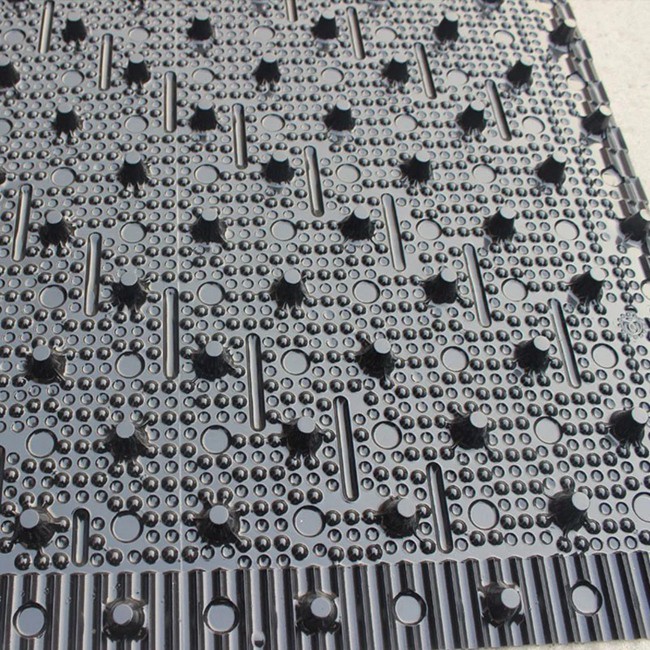

The manufacturing process of PVC filler mainly includes two steps: extrusion and molding. During the extrusion process, PVC particles are heated and extruded through a mold to form the desired filler shape. During the molding process, PVC particles are placed in molds with the desired shape and processed through heating and pressure to ultimately produce finished products. The precise control of these two steps ensures that the quality and performance of PVC fillers reach their optimal state.

In the field of air treatment, PVC fillers also play an important role. For example, in air filters, PVC packing can effectively remove pollutants from the air and improve air quality. Its good breathability and ventilation performance enable air to pass through the packing layer more smoothly, fully contact with other media in the filter, and improve filtration efficiency.

PVC fillers are known for their excellent chemical inertness, corrosion resistance, and wear resistance. It can maintain stable performance in various harsh environments and withstand long-term corrosion from chemical substances and impact from high-temperature fluids. In addition, PVC fillers also have excellent breathability and ventilation performance, thanks to their corrugated or hexagonal structure, which can significantly increase the breathable area of the filler bed and improve the efficiency of heat and mass exchange.

PVC (polyvinyl chloride) filler, as a widely used plastic filler, has demonstrated its unique advantages in various fields such as chemical engineering, environmental protection, water treatment, and air treatment. Another major advantage of PVC filler is its light weight, ease of processing and installation. This not only reduces installation costs, but also facilitates subsequent maintenance and cleaning work. At the same time, the surface of PVC filler is smooth and not easy to scale, which helps to maintain the cleanliness and efficient operation of equipment.

Recommended Products

Recently Viewed

Best Price Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower

Best Price Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower China Supplier Mini Closed Water Cooling Tower Price

China Supplier Mini Closed Water Cooling Tower Price Best Price Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower

Best Price Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower Best Price Mini Closed Water Cooling Tower Price

Best Price Mini Closed Water Cooling Tower Price Hot Sale Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower

Hot Sale Low Noise Bottle Type Round Mini FRP Open Water Cooling Tower

Contact Us

WEIFANG HENG AN IMP & EXP CO., LTD.