Welcome!

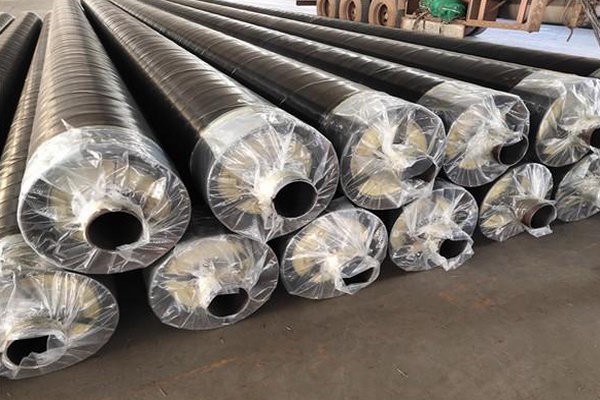

Custom Stainless Steel Elbow 3 Way Elbow Pipe Fittings

Product Description

Stainless steel three-way bend pipes have become indispensable connecting fittings in pipeline systems due to their excellent material properties, compact structure, and wide application fields. With the continuous advancement of industrial technology, the manufacturing process of stainless steel tee bends will be continuously optimized to meet more complex and diverse needs. In the future development, stainless steel tee bends will continue to play an important role in various fields, promoting the upgrading and development of pipeline systems.

The manufacturing process of stainless steel tee bends mainly includes hydraulic bulging and hot pressing forming. Among them, the hydraulic bulging process uses a dedicated hydraulic press to inject liquid into a tube blank with a diameter equal to that of a tee, and synchronously squeezes the tube blank through the two horizontal side cylinders of the hydraulic press, causing the metal material to flow in the mold cavity and bulge out the branch pipe. This process has high production efficiency and increases the thickness of the main pipe and shoulder wall, but requires a large tonnage of equipment, mainly suitable for the manufacture of standard wall thickness stainless steel tees.

The stainless steel material used for the stainless steel three-way bend pipe is smooth inside and outside, non-toxic, and not easy to rust. It has extremely high corrosion resistance and strength, ensuring the long-term stable operation of the pipeline system. Compared to traditional pipe joints, stainless steel tee bends have lower flow resistance and can effectively improve fluid transport efficiency. The three-way bend pipe has a compact design, occupies a small space, and is easy to install and maintain. Adopting advanced connection technologies such as welding and flange connections to ensure sealing performance and eliminate water leakage issues. Stainless steel three-way bend pipes have complete specifications and can be applied to complex environments such as high vacuum and strong pressure, meeting the needs of different fields.

Moreover, the maintenance of these elbows is relatively simple. Regular inspections and occasional cleaning are usually sufficient to ensure their longevity and optimal performance. In the event of damage or wear, the modular nature of piping systems makes it easy to replace individual components without disrupting the entire network.

In the realm of piping systems, the stainless steel 3-way elbow pipe stands out as a versatile component that plays a crucial role in fluid dynamics. This ingenious piece of hardware is designed to redirect the flow of liquids, gases, or even solids in three different directions, making it an essential element in various industries, including plumbing, HVAC, and chemical processing.

Recommended Products

Recently Viewed

Contact Us

Shandong Hongtai Metal Products Co., Ltd.