Welcome!

China Manufacturer Medicine Box Carton Erector Packing Sealing and Strapping Machine

Product Description

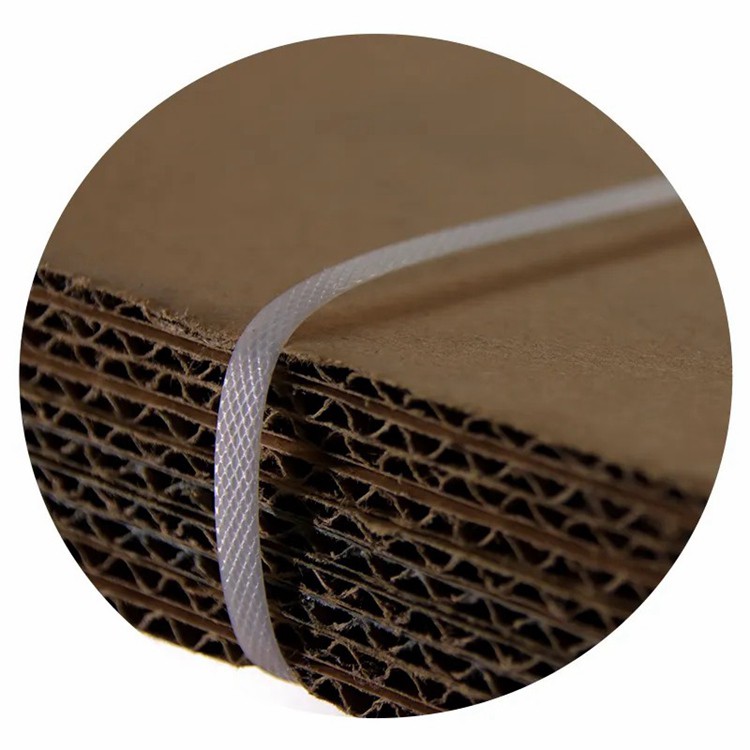

The design of strapping machines is often very user-friendly and easy to operate. Even inexperienced workers can quickly master the operating methods. At the same time, many strapping machines are also equipped with intelligent control systems that enable one click operation, further simplifying the operation process. The strapping machine adopts advanced strapping technology, which can ensure the stability and reliability of the strapping effect. Whether for products of different specifications or packaging materials of different materials, the strapping machine can provide consistent strapping effect, ensuring the beauty and firmness of the packaging.

The strapping machine can automatically complete the strapping process, significantly improving the packaging speed. Compared to manual tying, a tying machine can complete several hours of work for multiple workers, and the effect is more stable and uniform. This efficiency enables enterprises to quickly respond to large-scale packaging tasks and improve production efficiency. The strapping machine adopts advanced automation technology, such as automatic belt feeding, automatic positioning, automatic strapping and other functions, greatly reducing the labor intensity of workers. This not only improves production efficiency, but also reduces the error rate caused by human factors and enhances the overall quality of operations.

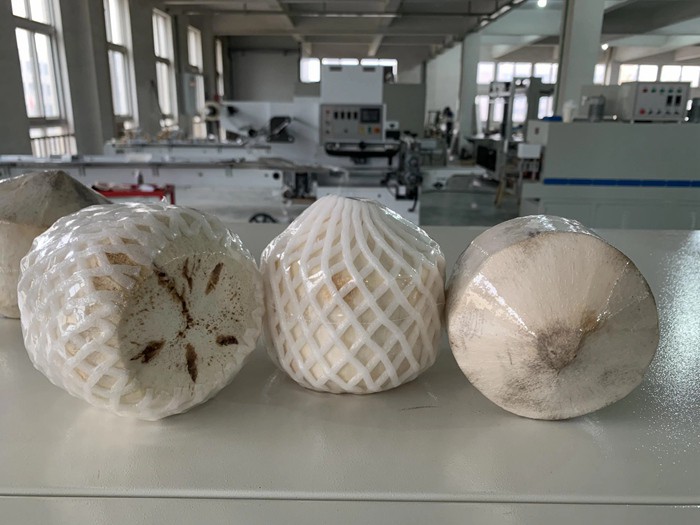

The plastic strapping machine is suitable for strapping small and medium weight packaging boxes, mainly using polypropylene straps, nylon straps, polyester straps, etc. This type of strapping machine is easy to operate and cost-effective, making it one of the most common types on the market. Especially suitable for handling plastic tape joints. By using methods such as electric heating welding, ultrasonic welding, high-frequency welding, or pulse welding, the plastic tape is melted and bonded to achieve a fastening effect. Electric strapping machines are usually suitable for fixed locations, while pneumatic strapping machines are widely used in various scenarios that require mobile operations due to their portability and flexibility.

As a widely used packaging equipment, the main function of a strapping machine is to use mechanical or electric devices to tighten and tie ropes, thin strips, or specific materials (such as plastic strips, steel strips) to prevent items from scattering, facilitate transportation, and storage. Whether in warehousing, logistics, packaging or other industries, strapping machines play an indispensable role.

Recommended Products

Recently Viewed

Paper Box Bundling Machine: Streamlined Packaging Efficiency

Paper Box Bundling Machine: Streamlined Packaging Efficiency Advanced Paper Box Bundling Machine: Smart Automation for Modern Packaging

Advanced Paper Box Bundling Machine: Smart Automation for Modern Packaging Auxiliary Packaging Machines: Your Partner in Smarter, Faster, and Greener Production

Auxiliary Packaging Machines: Your Partner in Smarter, Faster, and Greener Production Auxiliary Packaging Machines: Streamlining Efficiency and Precision

Auxiliary Packaging Machines: Streamlining Efficiency and Precision Auxiliary Packaging Machines: Precision, Efficiency, and Seamless Integration

Auxiliary Packaging Machines: Precision, Efficiency, and Seamless Integration

Contact Us

Shandong Sapphire Packaging Machinery Co., Ltd.