Welcome!

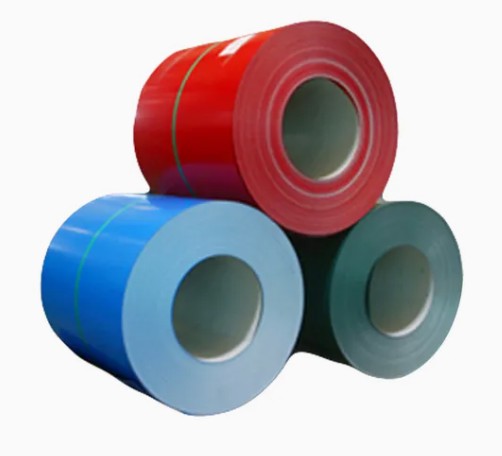

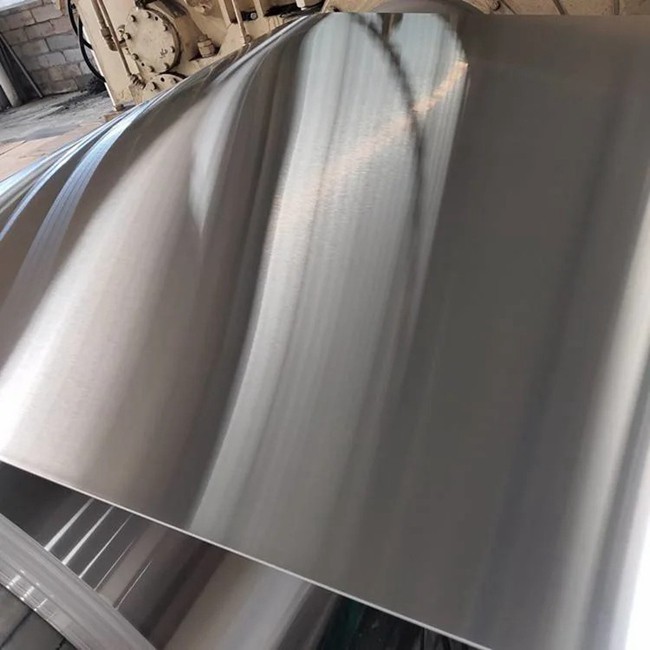

High Quality Building Material Roofing Sheets Steel-Products Carbon Steel Coil

Product Description

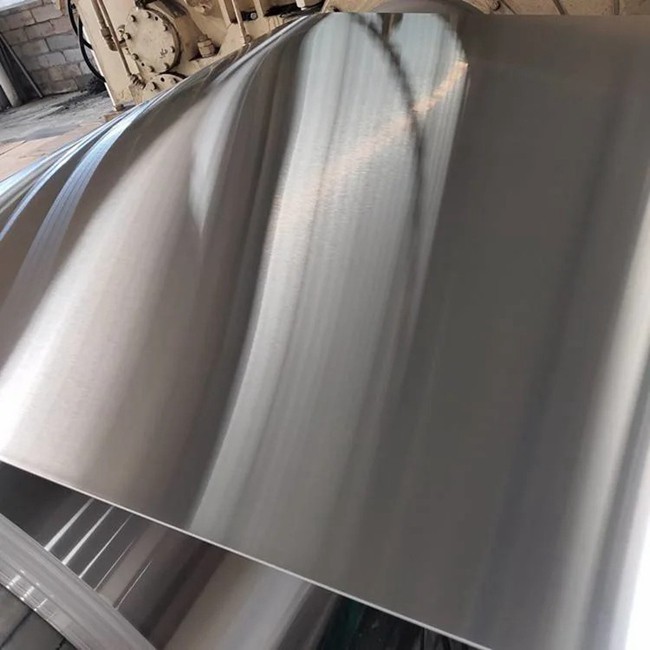

Hot dip galvanized steel coils have a rough appearance and a darker color, generally presenting a silver white color. Due to the influence of the manufacturing process, water streaks and droplets may appear on the surface. But its coating has strong adhesion and long service life. Cold galvanized steel coils have a smooth and bright appearance, and can be color passivated as needed to present different colors. But its coating is relatively thin and the anti-corrosion time is relatively short.

Hot dip galvanized steel coils are commonly used in fields that require high corrosion resistance and strength, such as marine engineering, chemical engineering, shipbuilding, aerospace, etc., due to their excellent anti-corrosion performance and strength. In these fields, hot-dip galvanized steel coils can effectively resist the erosion of materials by harsh environments. Cold dip galvanized steel coils are commonly used in fields such as construction, home appliances, automobiles, and light industry. Although its anti-corrosion performance is not as good as hot-dip galvanized steel coils, its cost is relatively low and it can meet the anti-corrosion requirements in general environments.

Galvanized steel coils are commonly used for components in building structures, such as beams, columns, purlins, as well as for building roofs, walls, and other areas. Its excellent anti-corrosion performance can protect building materials from corrosion by the atmosphere and water. Galvanized steel coils are also widely used in automobile manufacturing, such as manufacturing car bodies, doors, engine covers, and other components. Its corrosion resistance helps to extend the service life of automotive components.

Characteristics of galvanized steel coil

Strong corrosion resistance: Zinc has strong corrosion resistance and can protect steel from atmospheric, water, and chemical substances.

High surface smoothness: The galvanized steel surface is smooth and shiny, with good decorative properties.

Excellent processing performance: Galvanized steel coils can undergo various processing techniques such as bending, stamping, and shearing without affecting the overall performance of the steel.

Strong welding performance: Galvanized steel coils can be well connected with other materials and are widely used in the manufacturing of various mechanical equipment and industrial components.

Recommended Products

Recently Viewed

Contact Us

Henan XinChang Import and Export Trade Co., Ltd.