Welcome!

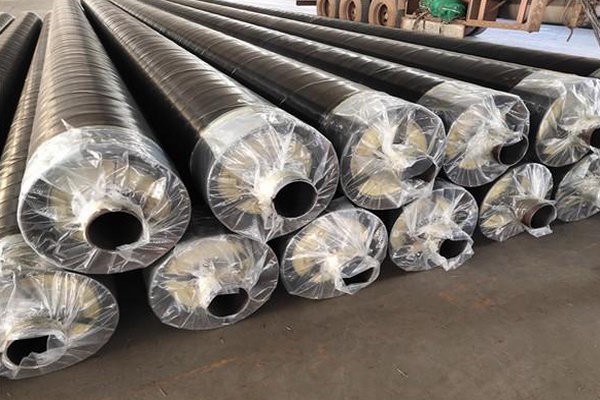

Hot Selling Stainless Steel Elbow 3 Way Elbow Pipe Fittings

Product Description

The manufacturing process of stainless steel tee bends mainly includes hydraulic bulging and hot pressing forming. Among them, the hydraulic bulging process uses a dedicated hydraulic press to inject liquid into a tube blank with a diameter equal to that of a tee, and synchronously squeezes the tube blank through the two horizontal side cylinders of the hydraulic press, causing the metal material to flow in the mold cavity and bulge out the branch pipe. This process has high production efficiency and increases the thickness of the main pipe and shoulder wall, but requires a large tonnage of equipment, mainly suitable for the manufacture of standard wall thickness stainless steel tees.

Installation of the stainless steel 3-way elbow pipe is straightforward, thanks to its compatibility with various connection methods, including welding, threading, and socket welding. This flexibility allows for easy integration into existing piping systems or the creation of new configurations tailored to specific needs.

The design of the 3-way elbow allows for a smooth transition of flow, minimizing turbulence and pressure drops. This is achieved through the precise angles and contours of the elbow, which are typically either 90 degrees or 45 degrees, depending on the specific requirements of the piping system.

Recommended Products

Recently Viewed

Contact Us

Shandong Hongtai Metal Products Co., Ltd.