Welcome!

Precision stainless steel spring strip

Product Description

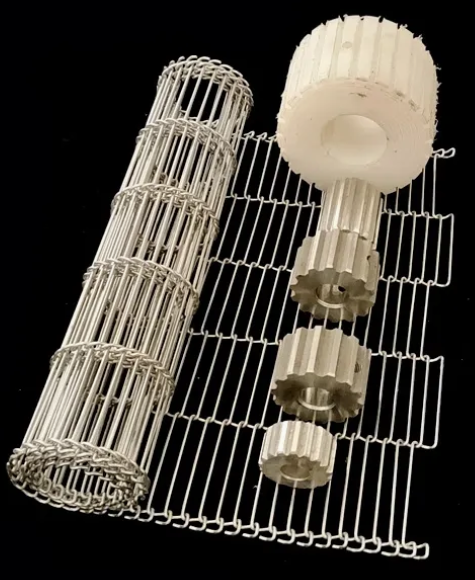

Precision stainless steel spring strip

Stainless steel spring strip is suitable for making springs and elastic elements, with excellent corrosion resistance and mechanical properties. Mainly used for making springs and elastic elements, its excellent corrosion resistance enables it to work stably for a long time in various corrosive environments. This material can resist corrosion from weakly corrosive media such as water and steam, as well as strong corrosive media such as acid, alkali, salt and other chemically corrosive media. The standards of stainless steel spring strip include GBT_24588-2009, etc., which ensures the reliability of its quality and performance.

There are many types of stainless steel spring strips, including tension springs, compression springs, torsion springs and precision springs. These springs can produce large elastic deformation when loaded, and the deformation disappears and returns to its original shape after unloading, with good elastic recovery ability. Not only does it have high yield strength, high tensile strength and high hardness, it also has good elasticity and fatigue resistance, and is suitable for making various parts that need to bear loads and maintain elasticity.

The materials of stainless steel spring strips include austenitic stainless steel, ferritic stainless steel, martensitic stainless steel and precipitation hardening stainless steel. Austenitic stainless steel: including 201 stainless steel (national standard grade 12Cr17Mn6Ni5N, unified digital code S35350), 301 stainless steel (national standard grade 12Cr17Ni7, unified digital code S30110), 304 stainless steel (national standard grade 06Cr19Ni10, unified digital code S30408) and 316 stainless steel (national standard grade 06Cr17Ni12Mo2, unified digital code S31608). These materials are widely used due to their excellent corrosion resistance and formability. Ferritic stainless steel: including 430 stainless steel (national standard grade 10Cr17, unified digital code S11710). This material is used in some specific application scenarios due to its good corrosion resistance. Martensitic stainless steel: including 420 stainless steel (GB 20Cr13, unified digital code S42020; GB 30Cr13, unified digital code S42030; GB 40Cr13, unified digital code S42040). These materials are used in applications that require high durability due to their high hardness and wear resistance. Precipitation hardening stainless steel: including 631 stainless steel (GB 07Cr17Ni7Al, unified digital code S51770). This material is used in some special applications due to its excellent mechanical properties and corrosion resistance.

Specifications and standards

The main standards for stainless steel spring strips include GB/T4231 and YB(T)11-83. GB/T4231 specifies the dimensions and allowable deviations of stainless steel cold-rolled strips for springs, while YB(T)11-83 specifies the wire standards for stainless steel springs, which are divided into Group A, Group B, and Group C according to tensile strength.

The dimensions and specifications of stainless steel spring strips include thickness and width. The thickness ranges from 0.10mm to 1.60mm, and the width ranges from 10mm to 250mm. See Table 5-227 and Table 5-228 for specific dimensions and allowable deviations.

Application Range

Stainless steel spring strips are widely used in many industries, including chemical machinery, electronics, etc., where the working environment requires corrosion resistance, medium temperature resistance, non-magnetic properties, etc. The design and production of stainless steel spring strips are carried out by professional spring factories. According to different working environments and usage requirements, appropriate materials and spring types are selected to ensure product performance and reliability.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.