Welcome!

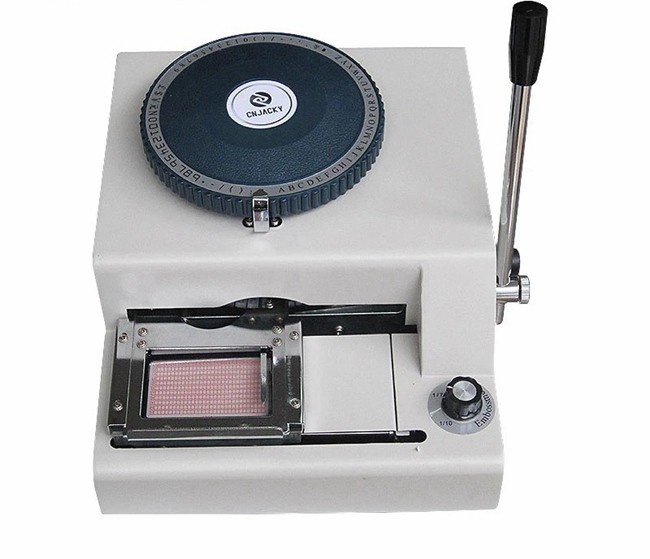

Customized Characters Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card

Product Description

Dog card embossing machine is usually designed with electric or pneumatic drive, which is able to automate the embossing process and greatly improve the production efficiency. Compared with manual production, it can complete the embossing of a large number of dog tags in a short period of time, reducing the tedious and time-consuming manual operation.

Automated operation not only improves production efficiency, but also significantly reduces production costs. Since the machine can work continuously and does not require frequent breaks, it maximizes the use of time resources and reduces errors and waste caused by improper manual operation or fatigue.

Using a card embossing machine for DIY production can not only exercise children's hands-on ability and creativity, but also enable them to better understand the knowledge of nature and plants, and cultivate artistic aesthetic ability. The price of card embossing machine is relatively affordable, suitable for families and schools and other places. At the same time, the overall production cost is also lower because most of the production materials are low-cost materials such as natural plants and paper.

Card embossing machines can produce a variety of unique patterns and textures through different combinations of dies and templates to meet personalized needs. Most of the modern card embossing machines adopt intelligent design, which is easy and convenient to operate, even children can easily get started under the guidance of adults. Card embossing machines are usually made of high-quality materials with good durability and safety. At the same time, there are protective devices inside the machine to prevent damage caused by operating errors.

Place the material to be embossed on the die, making sure it is centered and flat. If using a hot melt gun for heat embossing, heat the gun to the proper temperature in advance. Place the mold and material together in the embosser, adjust the pressure to the proper level, and gently press the handle of the embosser to emboss. Keep your hand steady during the embossing process and avoid applying too much force to avoid damaging the machine or the material. When pressing is complete, open the embosser and remove the mold and material. Carefully remove the embossed material from the mold and check if the embossing result is satisfactory. If further processing (e.g. hot foil fusing) is required, follow the appropriate steps.

The process of DIY making with a card embossing machine is relatively simple. In addition to the card embossing machine itself, you need to prepare embossing paper, scissors, flowers, plant leaves and other natural materials. Ensure that the chosen materials are dry and suitable for the embossing process. Choose a suitable embossing mold or template and install it on the embossing machine. Different molds can produce different patterns and textures, so choose according to actual needs.

Recommended Products

Recently Viewed

Wholesale PVC Card Embossing Machine 68 70 72 Character Plastic Card Plate Number Embosser

Wholesale PVC Card Embossing Machine 68 70 72 Character Plastic Card Plate Number Embosser Manufacturer From China PVC Card Embossing Machine 68 70 72 Character Plastic Card Plate Number Embosser

Manufacturer From China PVC Card Embossing Machine 68 70 72 Character Plastic Card Plate Number Embosser Manufacturer From China Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card

Manufacturer From China Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card Customized Characters Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card

Customized Characters Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card Metal Custom Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card

Metal Custom Manual Operate PVC ID Card Embosser and Letter Word Printer for Plastic Card

Contact Us

Zhengzhou Zomagtc Company Ltd.