Welcome!

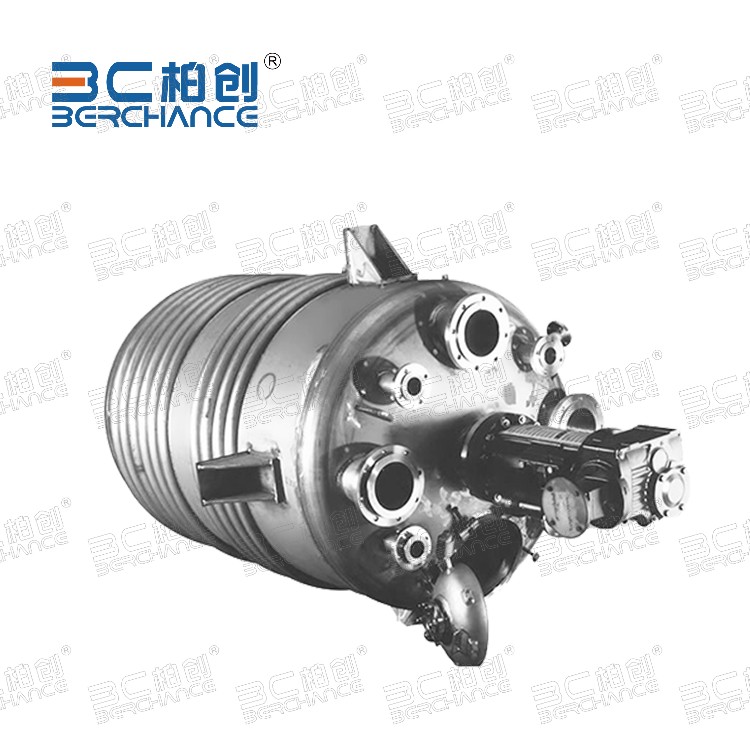

Stainless Steel (SS) Chemical Project Distillation Using High Pressure Limpet Coils Reaction Kettle

Product Description

Distillation vessels are widely used in various industries such as pharmaceuticals, chemicals, food, and light industry. In the pharmaceutical industry, distillation kettles are commonly used to extract active ingredients from drugs, such as extracting essential oils from plants or separating target products from fermentation broth. In the chemical industry, distillation kettles are used for the purification and separation of various chemicals, such as fraction cutting in petroleum processing and product purification in organic synthesis. In addition, in the food industry, distillation kettles are also used in the production process of extracting substances such as spices and alcohol.

Maintenance and upkeep

Strictly follow operating procedures and safety regulations to ensure the safety of operators.

Regularly inspect and maintain all equipment and accessories of the reactor to ensure its normal operation and extend its service life.

Pay attention to changes in temperature, pressure, and other parameters during the reaction process, and adjust control parameters in a timely manner to maintain a stable production process.

During shutdown or maintenance, it is necessary to follow the prescribed procedures for emptying, cleaning, and maintenance to ensure the good condition of the equipment.

Reaction vessels are widely used in industries such as petroleum, chemical, rubber, pesticides, dyes, pharmaceuticals, and food. In these industries, reaction vessels are used to complete processes such as sulfurization, nitration, hydrogenation, alkylation, polymerization, and condensation. For example, in the pharmaceutical industry, reaction vessels are used as critical steps in drug synthesis processes; In the chemical industry, it is used for the synthesis and purification of various chemicals.

Distillation kettle is one of the indispensable and important equipment in chemical production, with a compact structure, easy operation, good separation effect, and a wide range of applications. With the continuous advancement of technology and the expansion of application fields, the performance and functionality of distillation kettles will also be further improved and perfected. The distillation kettle converts electrical energy into thermal energy to heat materials, which has the advantages of easy cleaning, high efficiency (with an electrical energy utilization rate of over 95%), heating temperature of over 3000 ℃, and easy adjustment.

The distillation kettle has the advantages of simple structure, convenient operation, and good separation effect. Meanwhile, with the continuous advancement of technology, modern distillation kettles have also achieved higher levels of automation and a wider range of applications. In order to solve the problem of intermittent maintenance and cleaning of solid and high boiling point substances in the production process of traditional distillation kettles, modern distillation kettles have made many improvements in design, such as adding devices such as demisters and settling chambers, to improve production efficiency and product quality.

Recommended Products

Recently Viewed

Stainless Steel Coil Reactor with Efficient Heat Transfer and Temperature Control

Stainless Steel Coil Reactor with Efficient Heat Transfer and Temperature Control Stainless Steel Storage Tank for Corrosive Liquids and Food-Grade Applications

Stainless Steel Storage Tank for Corrosive Liquids and Food-Grade Applications Stainless Steel Fermentation Tank with Automatic Temperature Control for Biotech and Food Industries

Stainless Steel Fermentation Tank with Automatic Temperature Control for Biotech and Food Industries High-Efficiency Stainless Steel Heat Exchanger for Chemical, Food, and Pharmaceutical Industries

High-Efficiency Stainless Steel Heat Exchanger for Chemical, Food, and Pharmaceutical Industries Stainless Steel Mixing Tank for Food, Chemical, and Pharmaceutical Applications

Stainless Steel Mixing Tank for Food, Chemical, and Pharmaceutical Applications

Contact Us

Zibo Gyro Industrial Fabrication and Sales Co., Ltd.